HOT PRODUCTS TAGS

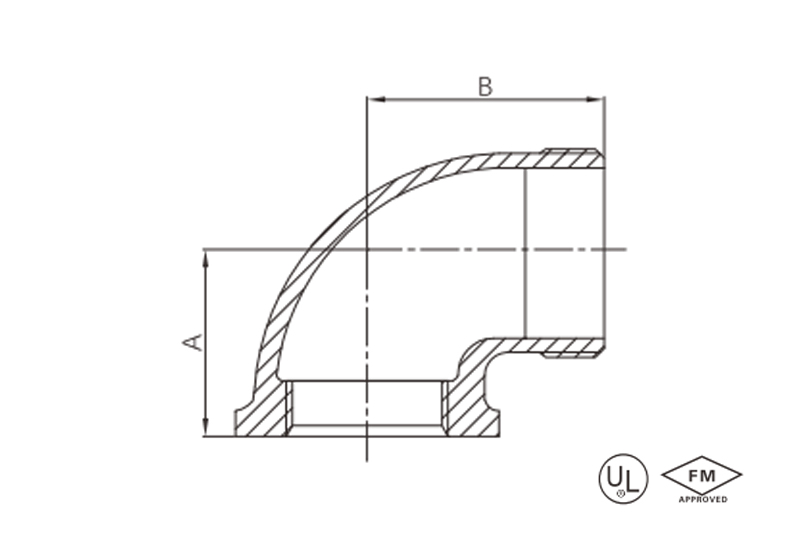

Malleable iron 90° street elbow

·Standard: ANSI/ASME B16.3

UL/FM

·Material: Malleable iron ASTM A197

·Thread: NPT

·W. pressure: Class 150, 300 psi (-29°C to 66°C)

Class 300, 1000 / 1500 / 2000 psi

(-29°C to 66°C)

·Surface: Black iron / hot dip galvanized

·Size Range: 1/2″ —6″ (Class 150)

1/4″—3″ (Class 300)

description

Malleable iron 90° street elbow, with secure socket connection, corrosion-resistant, easy to install, reliable and durable.

Specification

Available size

SIZE | A | B | ||

INCH | DN | MM | MM | MM |

1/2″ | 15 | 21.3 | 28.5 | 41.2 |

3/4″ | 20 | 26.7 | 33.3 | 48 |

1″ | 25 | 33.4 | 38.1 | 54.4 |

1-1/4″ | 32 | 42.2 | 44.5 | 62.2 |

1-1/2″ | 40 | 48.3 | 49.3 | 68.3 |

2″ | 50 | 60.3 | 57.2 | 82.8 |

2-1/2″ | 65 | 73 | 68.6 | 98 |

3″ | 80 | 88.9 | 78.2 | 114.6 |

4″ | 100 | 114.3 | 96.3 | 144.5 |

6″ | 150 | 168.3 | 130.3 | 204 |

1/4” | 8 | 13.7 | 23.9 | 36.6 |

3/8” | 10 | 17.1 | 26.9 | 41.4 |

1/2” | 15 | 21.3 | 31.8 | 50.8 |

3/4” | 20 | 26.7 | 36.6 | 55.6 |

1” | 25 | 33.4 | 41.4 | 65 |

1-1/4” | 32 | 42.2 | 49.3 | 73.2 |

1-1/2” | 40 | 48.3 | 54.1 | 79.5 |

2” | 50 | 60.3 | 63.5 | 93.7 |

2-1/2” | 65 | 73 | 74.7 | 114.3 |

3” | 80 | 88.9 | 85.9 | 130.3 |

application

- Wall-mounted equipment connections: Interfaces for wall-mounted equipment such as boilers and pumps, with external threads directly connected to equipment and internal threads connected to pipes, solving the problem of turning in narrow spaces.

- Dense wiring on instrument panels: Piping on the back of control cabinets and instrument panels, with small-sized elbows (e.g., 1/4″) enabling compact right-angle turns to avoid pipe crossings.

- High-pressure system safety upgrades: Air compressors and hydraulic stations with Class 300-grade piping, capable of withstanding 2000 psi high pressure, with threaded locking to prevent bursting.

- Corrosive environment direct connections: Hot-dip galvanized plates are used for seawater cooling pipes in coastal power plants and acid mist areas in chemical plants, replacing easily rusting flange connections.

- Emergency repair scenarios: Rapid repairs for pipe ruptures, with threaded connections eliminating the need for system shutdown and welding, enabling operation to resume within 30 minutes.

advantages

- Revolutionary dual-thread design:

- One head with straight thread (male): directly connected to the equipment at both ends;

- One end with internal thread (female) to connect to piping systems, which eliminates one joint and comes with leakage points reduced by 50%.

- Dual pressure rating coverage:

- _Class 150_ : General service, rating pressure 300 psi, temperature range -29°C to +66°C;

- Class 300 High-pressure specialized, with a 2000 psi burst pressure with a70% increase in safety margin.

- Seismic-resistant anti-loosening structure:

- Powder coated (black) to resist rust or corrosion. ▫Forged cast iron (ASTM A197) for high strength and mechanical impact resistance, 40% longer lifespan compared with regular nodular cast iron;

- Item Characteristics NPT tapered thread self-sealing design, which is resistant to vibration and has zero leakage.

- Full-scenario corrosion protection:

- hot-dip galvanized layer >80μm, salt spray test >1000 hours;

- e, Black iron using phosphating solution and can be used indoor dry environment.

- 90-second quick installation:

- No need for any specific tool, just manually tensioning, can save you 04hrs/node compared to welding.

packing

- Threaded Armor-Grade Protection:

- External threads fitted with silicone anti-collision caps, internal threads coated with food-grade anti-rust oil + heat-shrinkable film sealing;

- Elbow bodies wrapped in pearl cotton, embedded in high-density EPS molds to prevent transportation fractures.

- Pressure-Sensitive Smart Packaging:

- Class 150: Blue-labeled boxes, 30 pieces per box (≤1″), with internal compartment paper trays + humidity indicator cards;

- Class 300: Red-labeled box, 12 pieces per box, with a “high-pressure” lightning symbol printed on the box.

- Large-item special solution:

- ≥3″ elbows use a removable steel frame box with casters on the bottom for direct on-site transportation;

- NFC chips embedded inside the box for mobile phone sensing to obtain installation torque parameters.

- Error-proofing and traceability system:

- Product casting with “CL150/300” pressure rating markings;

- Outer box labeled with dual thread diagrams, arrows indicating “external thread → equipment, internal thread → pipeline.”

Available size

SIZE | A | B | ||

INCH | DN | MM | MM | MM |

1/2″ | 15 | 21.3 | 28.5 | 41.2 |

3/4″ | 20 | 26.7 | 33.3 | 48 |

1″ | 25 | 33.4 | 38.1 | 54.4 |

1-1/4″ | 32 | 42.2 | 44.5 | 62.2 |

1-1/2″ | 40 | 48.3 | 49.3 | 68.3 |

2″ | 50 | 60.3 | 57.2 | 82.8 |

2-1/2″ | 65 | 73 | 68.6 | 98 |

3″ | 80 | 88.9 | 78.2 | 114.6 |

4″ | 100 | 114.3 | 96.3 | 144.5 |

6″ | 150 | 168.3 | 130.3 | 204 |

1/4” | 8 | 13.7 | 23.9 | 36.6 |

3/8” | 10 | 17.1 | 26.9 | 41.4 |

1/2” | 15 | 21.3 | 31.8 | 50.8 |

3/4” | 20 | 26.7 | 36.6 | 55.6 |

1” | 25 | 33.4 | 41.4 | 65 |

1-1/4” | 32 | 42.2 | 49.3 | 73.2 |

1-1/2” | 40 | 48.3 | 54.1 | 79.5 |

2” | 50 | 60.3 | 63.5 | 93.7 |

2-1/2” | 65 | 73 | 74.7 | 114.3 |

3” | 80 | 88.9 | 85.9 | 130.3 |

- Wall-mounted equipment connections: Interfaces for wall-mounted equipment such as boilers and pumps, with external threads directly connected to equipment and internal threads connected to pipes, solving the problem of turning in narrow spaces.

- Dense wiring on instrument panels: Piping on the back of control cabinets and instrument panels, with small-sized elbows (e.g., 1/4″) enabling compact right-angle turns to avoid pipe crossings.

- High-pressure system safety upgrades: Air compressors and hydraulic stations with Class 300-grade piping, capable of withstanding 2000 psi high pressure, with threaded locking to prevent bursting.

- Corrosive environment direct connections: Hot-dip galvanized plates are used for seawater cooling pipes in coastal power plants and acid mist areas in chemical plants, replacing easily rusting flange connections.

- Emergency repair scenarios: Rapid repairs for pipe ruptures, with threaded connections eliminating the need for system shutdown and welding, enabling operation to resume within 30 minutes.

- Revolutionary dual-thread design:

- One head with straight thread (male): directly connected to the equipment at both ends;

- One end with internal thread (female) to connect to piping systems, which eliminates one joint and comes with leakage points reduced by 50%.

- Dual pressure rating coverage:

- _Class 150_ : General service, rating pressure 300 psi, temperature range -29°C to +66°C;

- Class 300 High-pressure specialized, with a 2000 psi burst pressure with a70% increase in safety margin.

- Seismic-resistant anti-loosening structure:

- Powder coated (black) to resist rust or corrosion. ▫Forged cast iron (ASTM A197) for high strength and mechanical impact resistance, 40% longer lifespan compared with regular nodular cast iron;

- Item Characteristics NPT tapered thread self-sealing design, which is resistant to vibration and has zero leakage.

- Full-scenario corrosion protection:

- hot-dip galvanized layer >80μm, salt spray test >1000 hours;

- e, Black iron using phosphating solution and can be used indoor dry environment.

- 90-second quick installation:

- No need for any specific tool, just manually tensioning, can save you 04hrs/node compared to welding.

- Threaded Armor-Grade Protection:

- External threads fitted with silicone anti-collision caps, internal threads coated with food-grade anti-rust oil + heat-shrinkable film sealing;

- Elbow bodies wrapped in pearl cotton, embedded in high-density EPS molds to prevent transportation fractures.

- Pressure-Sensitive Smart Packaging:

- Class 150: Blue-labeled boxes, 30 pieces per box (≤1″), with internal compartment paper trays + humidity indicator cards;

- Class 300: Red-labeled box, 12 pieces per box, with a “high-pressure” lightning symbol printed on the box.

- Large-item special solution:

- ≥3″ elbows use a removable steel frame box with casters on the bottom for direct on-site transportation;

- NFC chips embedded inside the box for mobile phone sensing to obtain installation torque parameters.

- Error-proofing and traceability system:

- Product casting with “CL150/300” pressure rating markings;

- Outer box labeled with dual thread diagrams, arrows indicating “external thread → equipment, internal thread → pipeline.”

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.