HOT PRODUCTS TAGS

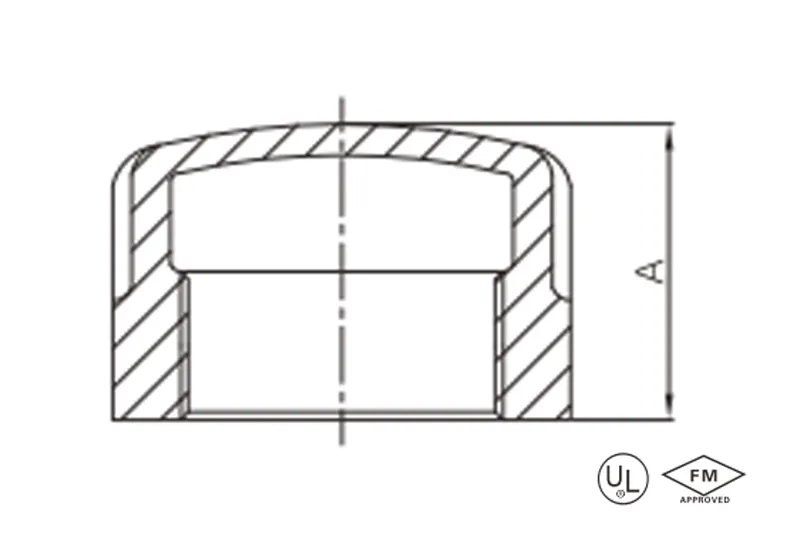

Malleable iron cap (Recessed)

·Standard: ASME B16.3

UL/FM

·Material: Malleable iron ASTM A197

·Thread: NPT

·W. pressure: Class 150, 300 psi (-29°C to 66°C)

Class 300, 1000 / 1500 / 2000 psi

(-29°C to 66°C)

·Surface: Black iron / hot dip galvanized

·Size Range: 1/2″ —6” (Class 150)

1/4″ —4” (Class 300)

description

Malleable iron cap (Recessed) is a malleable cast iron pipe fitting with a concave structure at the end, used to seal the end of a pipe.

Specification

Available size

Size | A (Min) | ||

Inch | DN | mm | mm |

1/2″ | 15 | 21.3 | 22.1 |

3/4″ | 20 | 26.7 | 24.6 |

1″ | 25 | 33.4 | 29.5 |

1-1/4″ | 32 | 42.2 | 32.5 |

1-1/2″ | 40 | 48.3 | 33.8 |

2″ | 50 | 60.3 | 36.8 |

2-1/2″ | 65 | 73.0 | 43.2 |

3″ | 80 | 88.9 | 45.7 |

4″ | 100 | 114.3 | 52.8 |

5” | 125 | 141.3 | 58.9 |

6” | 150 | 168.3 | 64.8 |

1/4” | 8 | 13.7 | 19.8 |

3/8” | 10 | 17.1 | 21.1 |

1/2” | 15 | 21.3 | 24.9 |

3/4” | 20 | 26.7 | 27.4 |

1” | 25 | 33.4 | 32 |

1-1/4” | 32 | 42.2 | 35.1 |

1-1/2” | 40 | 48.3 | 36.3 |

2” | 50 | 60.3 | 42.7 |

2-1/2” | 65 | 73.0 | 52.3 |

3” | 80 | 88.9 | 55.1 |

4” | 100 | 114.3 | 60.5 |

application

- End plugging of piping systems: permanent or temporary closure of open ports of water supply and drainage pipelines.

- Equipment maintenance isolation protection: seal the equipment interface during maintenance to prevent media leakage.

- Reserved interface of fire pipe network: seals the branch pipe port of the future expansion in the building fire protection system.

- Ship piping system protection: Closed deck pipe ports against marine salt spray.

- Industrial equipment pressure testing: Closed pipe ends for system tightness pressurization testing.

- Winter storage of agricultural irrigation systems: seal irrigation pipe network ports in winter to prevent frost cracking.

- Energy transmission pipeline maintenance: Block the isolation pipe section during oil and gas pipeline maintenance.

- Laboratory pipeline safety: seal the unused interface of the experimental gas pipeline.

advantages

- Groove-reinforced sealing: The recessed structure enhances the pressure-bearing capacity of the port seal.

- Quick-tightening seal: The standard thread design enables installation and removal in seconds.

- Extreme pressure protection: Maintains long-term zero-leakage sealing stability under high-pressure conditions.

- Full-environment corrosion resistance: Thickened galvanized coating resists chemical media and moisture corrosion.

- Wide size coverage: Fully compatible with micro-precision tubes to large industrial tubes.

- Impact-resistant structure: Reinforced groove design withstands external impact deformation.

- Temperature change adaptability: Maintains material structural integrity in extreme cold and high-temperature environments.

- Lifetime maintenance-free commitment: Special process significantly extends protective service life.

packing

- Groove-specific protective cover: Custom PE protective cover fits the curved surface of the groove to prevent scratches.

- Double protection for threaded ends: Screw cap + foam ring composite protection seals the thread.

- Individual impact protection: Bubble column bag completely covers the surface of the tube cap.

- Intelligent specification positioning: Honeycomb cardboard compartments are classified and fixed according to size.

- Visual specification identification: Transparent window on the outer box clearly displays the product size.

- Load-bearing Grading Solution: Small-sized vacuum-formed boxes/large-sized reinforced wooden boxes for separate packaging.

- Full-Process Traceability System: Laser engraving + smart QR code dual traceability.

- Warehouse Stacking Optimization: Boxes with embedded structures support ultra-high-density storage.

Available size

Size | A (Min) | ||

Inch | DN | mm | mm |

1/2″ | 15 | 21.3 | 22.1 |

3/4″ | 20 | 26.7 | 24.6 |

1″ | 25 | 33.4 | 29.5 |

1-1/4″ | 32 | 42.2 | 32.5 |

1-1/2″ | 40 | 48.3 | 33.8 |

2″ | 50 | 60.3 | 36.8 |

2-1/2″ | 65 | 73.0 | 43.2 |

3″ | 80 | 88.9 | 45.7 |

4″ | 100 | 114.3 | 52.8 |

5” | 125 | 141.3 | 58.9 |

6” | 150 | 168.3 | 64.8 |

1/4” | 8 | 13.7 | 19.8 |

3/8” | 10 | 17.1 | 21.1 |

1/2” | 15 | 21.3 | 24.9 |

3/4” | 20 | 26.7 | 27.4 |

1” | 25 | 33.4 | 32 |

1-1/4” | 32 | 42.2 | 35.1 |

1-1/2” | 40 | 48.3 | 36.3 |

2” | 50 | 60.3 | 42.7 |

2-1/2” | 65 | 73.0 | 52.3 |

3” | 80 | 88.9 | 55.1 |

4” | 100 | 114.3 | 60.5 |

- End plugging of piping systems: permanent or temporary closure of open ports of water supply and drainage pipelines.

- Equipment maintenance isolation protection: seal the equipment interface during maintenance to prevent media leakage.

- Reserved interface of fire pipe network: seals the branch pipe port of the future expansion in the building fire protection system.

- Ship piping system protection: Closed deck pipe ports against marine salt spray.

- Industrial equipment pressure testing: Closed pipe ends for system tightness pressurization testing.

- Winter storage of agricultural irrigation systems: seal irrigation pipe network ports in winter to prevent frost cracking.

- Energy transmission pipeline maintenance: Block the isolation pipe section during oil and gas pipeline maintenance.

- Laboratory pipeline safety: seal the unused interface of the experimental gas pipeline.

- Groove-reinforced sealing: The recessed structure enhances the pressure-bearing capacity of the port seal.

- Quick-tightening seal: The standard thread design enables installation and removal in seconds.

- Extreme pressure protection: Maintains long-term zero-leakage sealing stability under high-pressure conditions.

- Full-environment corrosion resistance: Thickened galvanized coating resists chemical media and moisture corrosion.

- Wide size coverage: Fully compatible with micro-precision tubes to large industrial tubes.

- Impact-resistant structure: Reinforced groove design withstands external impact deformation.

- Temperature change adaptability: Maintains material structural integrity in extreme cold and high-temperature environments.

- Lifetime maintenance-free commitment: Special process significantly extends protective service life.

- Groove-specific protective cover: Custom PE protective cover fits the curved surface of the groove to prevent scratches.

- Double protection for threaded ends: Screw cap + foam ring composite protection seals the thread.

- Individual impact protection: Bubble column bag completely covers the surface of the tube cap.

- Intelligent specification positioning: Honeycomb cardboard compartments are classified and fixed according to size.

- Visual specification identification: Transparent window on the outer box clearly displays the product size.

- Load-bearing Grading Solution: Small-sized vacuum-formed boxes/large-sized reinforced wooden boxes for separate packaging.

- Full-Process Traceability System: Laser engraving + smart QR code dual traceability.

- Warehouse Stacking Optimization: Boxes with embedded structures support ultra-high-density storage.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.