HOT PRODUCTS TAGS

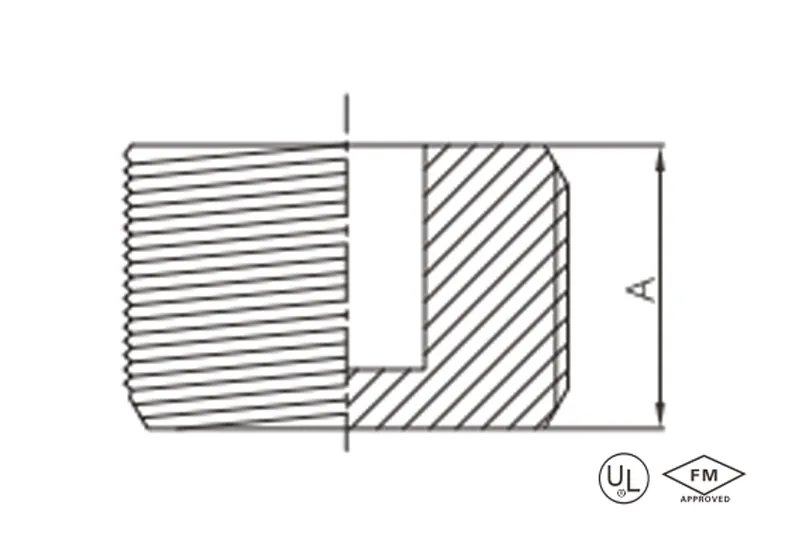

Malleable iron countersunk plug (Square socket)

·Standard: ASME B16.14

UL/FM

·Material: Malleable iron ASTM A197

·Thread: NPT

·W. pressure: Class 150, 300 psi (-29°C to 66°C)

·Surface: Black iron / hot dip galvanized

·Size Range: 1/2″ —4″

description

Malleable iron countersunk plug (Square socket) is a malleable cast iron pipe fitting with a countersunk head and a square socket, used to seal the end of the pipe and make the surface flush.

Specification

Available size

Size | A (Min) | ||

Inch | DN | mm | mm |

1/2″ | 15 | 21.3 | 14.2 |

3/4″ | 20 | 26.7 | 16.0 |

1″ | 25 | 33.4 | 19.1 |

1-1/4″ | 32 | 42.2 | 20.3 |

1-1/2″ | 40 | 48.3 | 21.1 |

2″ | 50 | 60.3 | 22.4 |

2-1/2″ | 65 | 73.0 | 27.2 |

3″ | 80 | 88.9 | 28.7 |

4″ | 100 | 114.3 | 31.0 |

application

- Wall-mounted pipe end sealing: Concealed sealing of wall-penetrating pipe ends maintains a smooth and aesthetically pleasing wall surface.

- Equipment integrated pipe protection: Sealing of internal pipe ends in mechanical equipment prevents foreign object intrusion.

- Fire protection system embedded interfaces: Sealing of reserved ports in fire protection networks that are flush with the wall surface.

- Ship deck pipe management: Sealing of deck pipe ends achieves anti-trip safety design.

- Industrial equipment test interfaces: Sealing embedded testing ports after pressure testing.

- Underground pipeline maintenance protection: Sealing underground pipeline ends to prevent silt buildup.

- Laboratory bench pipeline: Sealing gas/water interfaces on laboratory benches to maintain a smooth surface.

- Decorative pipeline end treatment: Sealing decorative metal railings/furniture pipeline ends.

advantages

- Countersunk flush seal: The embedded design ensures that the pipe opening is completely flush with the contact surface.

- Square hole quick operation: The square drive hole is compatible with standard tools for quick installation.

- High-pressure dynamic seal: Maintains long-term zero leakage stability under extreme conditions.

- Full-environment corrosion resistance: Thickened galvanized coating resists moisture and chemical corrosion.

- Impact-resistant reinforced structure: Countersunk design enhances resistance to external impact forces.

- Wide size coverage capability: Compatible with micro to large-scale industrial pipeline systems.

- Temperature extremes adaptability: Maintains seal integrity in harsh cold and high-temperature environments.

- Lifetime maintenance-free guarantee: Specialized manufacturing processes significantly extend protective lifespan.

packing

- Countersunk Face-Specific Protective Pad: Custom PE soft pad conforms to the countersunk curved surface to prevent scratches.

- Square Hole Dust-Proof Sealing Cover: Dedicated screw cap protects the square drive hole structure.

- Threaded End Dual Protection: Screw cap + foam ring composite protection seals the threads.

- Individual Shock-Resistant Envelopment: Bubble column bag completely wraps the tube plug surface.

- Smart Size-Specific Positioning: Honeycomb cardboard compartments categorize and secure items by size.

- Visual Identification System: Transparent windows on the outer box clearly display product specifications.

- Full-Process Traceability Management: Laser engraving + smart QR codes provide dual traceability.

Available size

Size | A (Min) | ||

Inch | DN | mm | mm |

1/2″ | 15 | 21.3 | 14.2 |

3/4″ | 20 | 26.7 | 16.0 |

1″ | 25 | 33.4 | 19.1 |

1-1/4″ | 32 | 42.2 | 20.3 |

1-1/2″ | 40 | 48.3 | 21.1 |

2″ | 50 | 60.3 | 22.4 |

2-1/2″ | 65 | 73.0 | 27.2 |

3″ | 80 | 88.9 | 28.7 |

4″ | 100 | 114.3 | 31.0 |

- Wall-mounted pipe end sealing: Concealed sealing of wall-penetrating pipe ends maintains a smooth and aesthetically pleasing wall surface.

- Equipment integrated pipe protection: Sealing of internal pipe ends in mechanical equipment prevents foreign object intrusion.

- Fire protection system embedded interfaces: Sealing of reserved ports in fire protection networks that are flush with the wall surface.

- Ship deck pipe management: Sealing of deck pipe ends achieves anti-trip safety design.

- Industrial equipment test interfaces: Sealing embedded testing ports after pressure testing.

- Underground pipeline maintenance protection: Sealing underground pipeline ends to prevent silt buildup.

- Laboratory bench pipeline: Sealing gas/water interfaces on laboratory benches to maintain a smooth surface.

- Decorative pipeline end treatment: Sealing decorative metal railings/furniture pipeline ends.

- Countersunk flush seal: The embedded design ensures that the pipe opening is completely flush with the contact surface.

- Square hole quick operation: The square drive hole is compatible with standard tools for quick installation.

- High-pressure dynamic seal: Maintains long-term zero leakage stability under extreme conditions.

- Full-environment corrosion resistance: Thickened galvanized coating resists moisture and chemical corrosion.

- Impact-resistant reinforced structure: Countersunk design enhances resistance to external impact forces.

- Wide size coverage capability: Compatible with micro to large-scale industrial pipeline systems.

- Temperature extremes adaptability: Maintains seal integrity in harsh cold and high-temperature environments.

- Lifetime maintenance-free guarantee: Specialized manufacturing processes significantly extend protective lifespan.

- Countersunk Face-Specific Protective Pad: Custom PE soft pad conforms to the countersunk curved surface to prevent scratches.

- Square Hole Dust-Proof Sealing Cover: Dedicated screw cap protects the square drive hole structure.

- Threaded End Dual Protection: Screw cap + foam ring composite protection seals the threads.

- Individual Shock-Resistant Envelopment: Bubble column bag completely wraps the tube plug surface.

- Smart Size-Specific Positioning: Honeycomb cardboard compartments categorize and secure items by size.

- Visual Identification System: Transparent windows on the outer box clearly display product specifications.

- Full-Process Traceability Management: Laser engraving + smart QR codes provide dual traceability.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.