HOT PRODUCTS TAGS

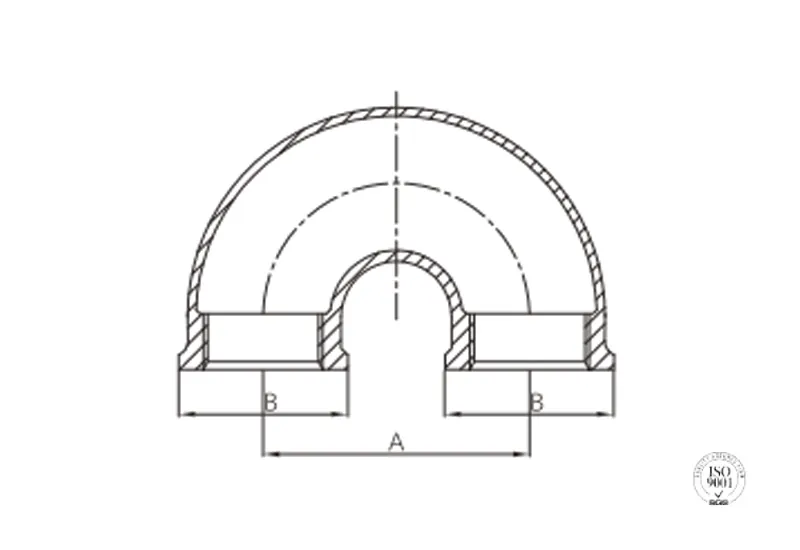

Malleable iron open-pattern return bend

·Standard: ASME B16.3

ISO

·Material: Malleable iron ASTM A197

·Thread: NPT

·W. pressure: Class 150, 300 psi (-29°C to 66°C)

·Surface: Black iron / hot dip galvanized

·Size Range: 1/2″ —2″

description

Malleable iron open-pattern return bend is a kind of malleable cast iron pipe fitting with an open bending structure, which is used in pipeline systems to achieve 180-degree return connection of pipelines.

Specification

Available size

Size | A | ||

Inch | DN | mm | mm |

1/2″ | 15 | 21.3 | 38.1 |

1-1/4″ | 32 | 42.2 | 76.2 |

1-1/2″ | 40 | 48.3 | 88.9 |

2″ | 50 | 60.3 | 101.6 |

application

- HVAC System U-shaped Loop: Connect heating pipes to form a closed loop for balanced distribution of heat medium.

- Industrial Equipment Cooling Circulation: Establish a compact 180° return pipe between the cooling tower and equipment.

- Ship Engine Room Compact Piping: Achieve 180° pipe turns in confined spaces to save installation space.

- Chemical Reactor Bypass: Establish a short-distance return detection channel at the inlet and outlet of the reactor.

- Solar hot water system: Forms a closed-loop freeze-proof circulation loop between collector arrays.

- Laboratory equipment piping: Compact return connections for precision instrument cooling water systems.

- Fire pump room piping optimization: Short-distance 180° turn connections at the inlet and outlet of fire pumps.

- Agricultural irrigation return system: Forms a freeze-proof return loop at the end of greenhouse irrigation networks.

advantages

- Compact 180°Turn: Open design for easy pipeline turning in a minimal space.

- Dual Interface Precision Alignment: The optimized elbow design will ensure that pipes are straightly connected at both ends.

- High pressure fluid flow: smooth channel design is to reduce the loss of energy and turbulence so as to ensure continuity of delivery at low pressure difference.

- Chemical, or any Moisture Media: Thickened zinc coating is just resistant to all spread of corrosion from moisture and chemical media.

- Rapid Maintenance: The open design allows visual inspection and maintenance of exposed installations.

- Water Hammer Resistance: Full support through reinforced bend structure of system-pressure fluctuations

- Stability Over Extreme Temperatures: Material is stable at high temperatures and has no loss in structural integrity.

- Lifetime Maintenance-Free Guarantee: Lengthens lifespan with unique casting process.

packing

- Curved Surface Protective Pad: Custom PE foam is bonded to the 180° curved surface to prevent collisions.

- Threaded End Dual Protection: A combination of a screw cap and foam ring provides composite protection for the threaded ends.

- Single-Unit Shock-Absorbing Wrap: Bubble column bags completely cover the surface of the elbow.

- Open-Structure Filling: Internal filling with deformable foam prevents deformation during transportation.

- Smart size-specific positioning: Honeycomb cardboard compartments are categorized and secured by size.

- Visual flow direction markers: Outer boxes are printed with installation flow direction arrows and angle markers.

- Full-process traceability system: Laser engraving + smart QR codes for dual traceability.

- Anti-rolling packing design: Anti-rolling slots inside the box ensure transportation stability.

Available size

Size | A | ||

Inch | DN | mm | mm |

1/2″ | 15 | 21.3 | 38.1 |

1-1/4″ | 32 | 42.2 | 76.2 |

1-1/2″ | 40 | 48.3 | 88.9 |

2″ | 50 | 60.3 | 101.6 |

- HVAC System U-shaped Loop: Connect heating pipes to form a closed loop for balanced distribution of heat medium.

- Industrial Equipment Cooling Circulation: Establish a compact 180° return pipe between the cooling tower and equipment.

- Ship Engine Room Compact Piping: Achieve 180° pipe turns in confined spaces to save installation space.

- Chemical Reactor Bypass: Establish a short-distance return detection channel at the inlet and outlet of the reactor.

- Solar hot water system: Forms a closed-loop freeze-proof circulation loop between collector arrays.

- Laboratory equipment piping: Compact return connections for precision instrument cooling water systems.

- Fire pump room piping optimization: Short-distance 180° turn connections at the inlet and outlet of fire pumps.

- Agricultural irrigation return system: Forms a freeze-proof return loop at the end of greenhouse irrigation networks.

- Compact 180°Turn: Open design for easy pipeline turning in a minimal space.

- Dual Interface Precision Alignment: The optimized elbow design will ensure that pipes are straightly connected at both ends.

- High pressure fluid flow: smooth channel design is to reduce the loss of energy and turbulence so as to ensure continuity of delivery at low pressure difference.

- Chemical, or any Moisture Media: Thickened zinc coating is just resistant to all spread of corrosion from moisture and chemical media.

- Rapid Maintenance: The open design allows visual inspection and maintenance of exposed installations.

- Water Hammer Resistance: Full support through reinforced bend structure of system-pressure fluctuations

- Stability Over Extreme Temperatures: Material is stable at high temperatures and has no loss in structural integrity.

- Lifetime Maintenance-Free Guarantee: Lengthens lifespan with unique casting process.

- Curved Surface Protective Pad: Custom PE foam is bonded to the 180° curved surface to prevent collisions.

- Threaded End Dual Protection: A combination of a screw cap and foam ring provides composite protection for the threaded ends.

- Single-Unit Shock-Absorbing Wrap: Bubble column bags completely cover the surface of the elbow.

- Open-Structure Filling: Internal filling with deformable foam prevents deformation during transportation.

- Smart size-specific positioning: Honeycomb cardboard compartments are categorized and secured by size.

- Visual flow direction markers: Outer boxes are printed with installation flow direction arrows and angle markers.

- Full-process traceability system: Laser engraving + smart QR codes for dual traceability.

- Anti-rolling packing design: Anti-rolling slots inside the box ensure transportation stability.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.