HOT PRODUCTS TAGS

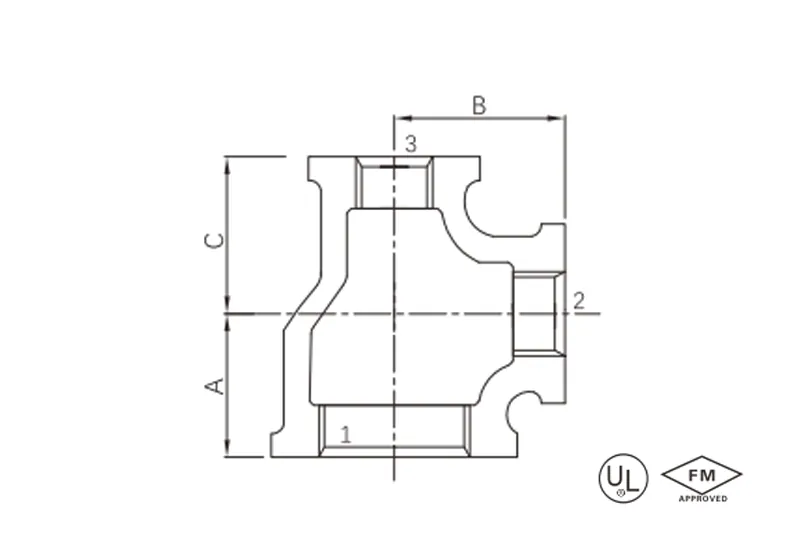

Malleable iron reducing tee (Unequal 3 ways)

·Standard: ANSI/ASME B16.3

UL/FM

·Material: Malleable iron ASTM A197

·Thread: NPT

·W. pressure: Class 150, 300 psi (-29°C to 66°C)

·Surface: Black iron / hot dip galvanized

·Size Range: 1″ x 1/2″ x 3/4″ —2″ x 1-1/4″ x 1-1/2″ (Class 150)

description

Malleable iron unequal reducing tee offers flexible adaptation with three different diameters, featuring high pressure resistance, wear resistance, and convenient installation.

Specification

Available size

SIZE(1 x 3 x 2) | A | B | C | ||

INCH | DN | MM | MM | MM | MM |

1″ x 1/2″ x 3/4″ | 25 x 15 x 20 | 33.4 x 21.3 x 26.7 | 32 | 35.5 | 30.5 |

1-1/4″ x 3/4″ x 1/2″ | 32 x 20 x 15 | 42.2 x 26.7 x 21.3 | 35 | 38 | 29 |

1-1/4″ x 1″ x 1/2″ | 32 x 25 x 15 | 42.2 x 33.4 x 21.3 | 34 | 38.9 | 32 |

1-1/4″ x 1/2″ x 1″ | 32 x 15 x 25 | 42.2 x 21.3 x 33.4 | 40.1 | 42.4 | 34.5 |

1-1/4″ x 1″ x 3/4″ | 32 x 25 x 20 | 42.2 x 33.4 x 26.7 | 36.8 | 41.2 | 34.8 |

1-1/4″ x 3/4″ x 1″ | 32 x 20 x 25 | 42.2 x 26.7 x 33.4 | 40.1 | 42.4 | 36.8 |

1-1/2″ x 1/2″ x 1″ | 40 x 15 x 25 | 48.3 x 21.3 x 33.4 | 37 | 41 | 32 |

1-1/2″ x 1-1/4″ x 3/4″ | 40 x 32 x 20 | 48.3 x 42.2 x 26.7 | 44 | 47 | 41.5 |

1-1/2″ x 3/4″ x 1-1/4″ | 40 x 20 x 32 | 48.3 x 26.7 x 42.2 | 38.6 | 44.5 | 36.3 |

1-1/2″ x 1-1/4″ x 1″ | 40 x 32 x 25 | 48.3 x 42.2 x 33.4 | 41.9 | 45.7 | 40.1 |

1-1/2″ x 1″ x 1-1/4″ | 40 x 25 x 32 | 48.3 x 33.4 x 42.2 | 46 | 48 | 42 |

2″ x 1″ x 1-1/2″ | 50 x 25 x 40 | 60.3 x 33.4 x 48.3 | 51.3 | 54.9 | 45.7 |

2″ x 1-1/2″ x 1″ | 50 x 40 x 25 | 60.3 x 48.3 x 33.4 | 43.9 | 51.3 | 41.9 |

2″ x 1-1/2″ x 1-1/4″ | 50 x 40 x 32 | 60.3 x 48.3 x 42.2 | 48.3 | 53.3 | 46.2 |

2″ x 1-1/4″ x 1-1/2″ | 50 x 32 x 40 | 60.3 x 42.2 x 48.3 | 51.3 | 54.9 | 47.8 |

application

- Building Plumbing Systems: Connecting complex piping systems with three different pipe diameters to accommodate the varying flow requirements of multiple kitchen and bathroom appliances.

- Fire Protection Piping Systems: Achieving precise multi-level pressure distribution when main pipes branch off to different specifications of sprinkler heads and fire hydrants.

- HVAC Systems: Distributing chilled water from the main pipe to terminal equipment such as fan coil units and fresh air handling units to address simultaneous heating and cooling requirements for multiple pipe diameters.

- Industrial Fluid Conveyance: Providing customized non-standard diameter energy supply interfaces for series or parallel multi-model equipment (such as reactors and compressors).

advantages

- Three-way reducer adapter: Three ports of different sizes that allow it to accommodate various pipe diameters in more elaborate piping systems.

- High Pressure Wear Resistance Structure: Strengthen cast quality to eliminate frequent pressure fluctuation and media abrasion, so that it increases greatly the service life.

- rustproof in all directions: The high-grade ductile iron base material is matched with a full-inclusion-edged galvanized or black-iron surface to resist corrosion from any direction.

- Ease of Installation: Threaded ends (NPT) as a standard feature add efficiency to market standardization by offering easy installation options for multi-diameter piping systems Global Engineering: ANSI/UL standards for safety and compliance International Standard Certification

packing

- Individual protection: Wrapped in rust-proof oil paper + bubble wrap cushioning to prevent surface scratches and rust.

- Bulk packing: Sorted by specification and packed into reinforced cardboard boxes, with moisture-proof wood shavings filled between layers.

- Labeling system: Outer boxes are spray-printed with size codes, quantity, and upward-facing marks, with support for customer-specific information.

- Bulk transportation: Palletized stacking, secured with steel straps, suitable for container freight.

Available size

SIZE(1 x 3 x 2) | A | B | C | ||

INCH | DN | MM | MM | MM | MM |

1″ x 1/2″ x 3/4″ | 25 x 15 x 20 | 33.4 x 21.3 x 26.7 | 32 | 35.5 | 30.5 |

1-1/4″ x 3/4″ x 1/2″ | 32 x 20 x 15 | 42.2 x 26.7 x 21.3 | 35 | 38 | 29 |

1-1/4″ x 1″ x 1/2″ | 32 x 25 x 15 | 42.2 x 33.4 x 21.3 | 34 | 38.9 | 32 |

1-1/4″ x 1/2″ x 1″ | 32 x 15 x 25 | 42.2 x 21.3 x 33.4 | 40.1 | 42.4 | 34.5 |

1-1/4″ x 1″ x 3/4″ | 32 x 25 x 20 | 42.2 x 33.4 x 26.7 | 36.8 | 41.2 | 34.8 |

1-1/4″ x 3/4″ x 1″ | 32 x 20 x 25 | 42.2 x 26.7 x 33.4 | 40.1 | 42.4 | 36.8 |

1-1/2″ x 1/2″ x 1″ | 40 x 15 x 25 | 48.3 x 21.3 x 33.4 | 37 | 41 | 32 |

1-1/2″ x 1-1/4″ x 3/4″ | 40 x 32 x 20 | 48.3 x 42.2 x 26.7 | 44 | 47 | 41.5 |

1-1/2″ x 3/4″ x 1-1/4″ | 40 x 20 x 32 | 48.3 x 26.7 x 42.2 | 38.6 | 44.5 | 36.3 |

1-1/2″ x 1-1/4″ x 1″ | 40 x 32 x 25 | 48.3 x 42.2 x 33.4 | 41.9 | 45.7 | 40.1 |

1-1/2″ x 1″ x 1-1/4″ | 40 x 25 x 32 | 48.3 x 33.4 x 42.2 | 46 | 48 | 42 |

2″ x 1″ x 1-1/2″ | 50 x 25 x 40 | 60.3 x 33.4 x 48.3 | 51.3 | 54.9 | 45.7 |

2″ x 1-1/2″ x 1″ | 50 x 40 x 25 | 60.3 x 48.3 x 33.4 | 43.9 | 51.3 | 41.9 |

2″ x 1-1/2″ x 1-1/4″ | 50 x 40 x 32 | 60.3 x 48.3 x 42.2 | 48.3 | 53.3 | 46.2 |

2″ x 1-1/4″ x 1-1/2″ | 50 x 32 x 40 | 60.3 x 42.2 x 48.3 | 51.3 | 54.9 | 47.8 |

- Building Plumbing Systems: Connecting complex piping systems with three different pipe diameters to accommodate the varying flow requirements of multiple kitchen and bathroom appliances.

- Fire Protection Piping Systems: Achieving precise multi-level pressure distribution when main pipes branch off to different specifications of sprinkler heads and fire hydrants.

- HVAC Systems: Distributing chilled water from the main pipe to terminal equipment such as fan coil units and fresh air handling units to address simultaneous heating and cooling requirements for multiple pipe diameters.

- Industrial Fluid Conveyance: Providing customized non-standard diameter energy supply interfaces for series or parallel multi-model equipment (such as reactors and compressors).

- Three-way reducer adapter: Three ports of different sizes that allow it to accommodate various pipe diameters in more elaborate piping systems.

- High Pressure Wear Resistance Structure: Strengthen cast quality to eliminate frequent pressure fluctuation and media abrasion, so that it increases greatly the service life.

- rustproof in all directions: The high-grade ductile iron base material is matched with a full-inclusion-edged galvanized or black-iron surface to resist corrosion from any direction.

- Ease of Installation: Threaded ends (NPT) as a standard feature add efficiency to market standardization by offering easy installation options for multi-diameter piping systems Global Engineering: ANSI/UL standards for safety and compliance International Standard Certification

- Individual protection: Wrapped in rust-proof oil paper + bubble wrap cushioning to prevent surface scratches and rust.

- Bulk packing: Sorted by specification and packed into reinforced cardboard boxes, with moisture-proof wood shavings filled between layers.

- Labeling system: Outer boxes are spray-printed with size codes, quantity, and upward-facing marks, with support for customer-specific information.

- Bulk transportation: Palletized stacking, secured with steel straps, suitable for container freight.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.