HOT PRODUCTS TAGS

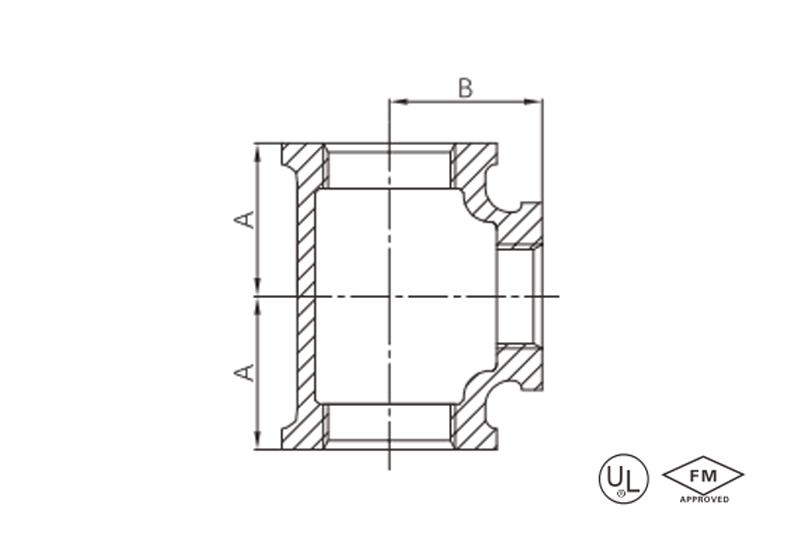

Malleable iron reducing tee

·Standard: ANSI/ASME B16.3

UL/FM

·Material: Malleable iron ASTM A197

·Thread: NPT

·W. pressure: Class 150, 300 psi (-29°C to 66°C)

Class 300, 1000 / 1500 / 2000 psi

(-29°C to 66°C)

·Surface: Black iron / hot dip galvanized

·Size Range: 3/4″ x 3/4″ x 1/2″ —4″ x 4″ x 3″ (Class 150)

1/2” x 1/2” x 3/8”—4” x 4” x 3” (Class 300)

description

Malleable iron reducing tee, with precise diameter reduction, firm connection, pressure and corrosion resistance, suitable for diverse pipelines.

Specification

Available size

| SIZE | A | B | ||

| INCH | DN | MM | MM | MM |

| 3/4″ x 3/4″ x 1/2″ | 20 x 20 x 15 | 26.7 x 26.7 x 21.3 | 30.5 | 31 |

| 1″ x 1″ x 1/4″ | 25 x 25 x 8 | 33.4 x 33.4 x 13.7 | 28.2 | 31 |

| 1″ x 1″ x 3/8″ | 25 x 25 x 10 | 33.4 x 33.4 x 17.1 | 30 | 32.3 |

| 1″ x 1″ x 1/2″ | 25 x 25 x 15 | 33.4 x 33.4 x 21.3 | 32 | 35.5 |

| 1″ x 1″ x 3/4″ | 25 x 25 x 20 | 33.4 x 33.4 x 26.7 | 34.8 | 36.8 |

| 1-1/4″ x 1-1/4″ x 3/8″ | 32 x 32 x 10 | 42.2 x 42.2 x 17.1 | 32 | 36.6 |

| 1-1/4″ x 1-1/4″ x 1/2″ | 32 x 32 x 15 | 42.2 x 42.2 x 21.3 | 34 | 38.9 |

| 1-1/4″ x 1-1/4″ x 3/4″ | 32 x 32 x 20 | 42.2 x 42.2 x 26.7 | 36.8 | 41.2 |

| 1-1/4″ x 1-1/4″ x 1″ | 32 x 32 x 25 | 42.2 x 42.2 x 33.4 | 40.1 | 42.4 |

| 1-1/2″ x 1-1/2″ x 1/2″ | 40 x 40 x 15 | 48.3 x 48.3 x 21.3 | 35.8 | 42.2 |

| 1-1/2″ x 1-1/2″ x 3/4″ | 40 x 40 x 20 | 48.3 x 48.3 x 26.7 | 38.6 | 44.5 |

| 1-1/2″ x 1-1/2″ x 1″ | 40 x 40 x 25 | 48.3 x 48.3 x 33.4 | 41.9 | 45.7 |

| 1-1/2″ x 1-1/2″ x 1-1/4″ | 40 x 40 x 32 | 48.3 x 48.3 x 42.2 | 46.2 | 47.8 |

| 2″ x 2″ x 1/2″ | 50 x 50 x 15 | 60.3 x 60.3 x 21.3 | 37.9 | 47.8 |

| 2″ x 2″ x 3/4″ | 50 x 50 x 20 | 60.3 x 60.3 x 26.7 | 40.6 | 50 |

| 2″ x 2″ x 1″ | 50 x 50 x 25 | 60.3 x 60.3 x 33.4 | 43.9 | 51.3 |

| 2″ x 2″ x 1-1/4″ | 50 x 50 x 32 | 60.3 x 60.3 x 42.2 | 48.3 | 53.3 |

| 2″ x 2″ x 1-1/2″ | 50 x 50 x 40 | 60.3 x 60.3 x 48.3 | 51.3 | 54.9 |

| 2-1/2″ x 2-1/2″ x 1/2″ | 65 x 65 x 15 | 73.0 x 73.0 x 21.3 | 41 | 57 |

| 2-1/2″ x 2-1/2″ x 3/4″ | 65 x 65 x 20 | 73.0 x 73.0 x 26.7 | 44.2 | 58.9 |

| 2-1/2″ x 2-1/2″ x 1″ | 65 x 65 x 25 | 73.0 x 73.0 x 33.4 | 47.5 | 60.2 |

| 2-1/2″ x 2-1/2″ x 1-1/4″ | 65 x 65 x 32 | 73.0 x 73.0 x 42.2 | 51.8 | 62.2 |

| 2-1/2″ x 2-1/2″ x 1-1/2″ | 65 x 65 x 40 | 73.0 x 73.0 x 48.3 | 54.9 | 63.8 |

| 2-1/2″ x 2-1/2″ x 2″ | 65 x 65 x 50 | 73.0 x 73.0 x 60.3 | 60.7 | 66 |

| 3″ x 3″ x 1/2″ | 80 x 80 x 15 | 88.9 x 88.9 x 21.3 | 42 | 64 |

| 3″ x 3″ x 3/4″ | 80 x 80 x 20 | 88.9 x 88.9 x 26.7 | 47.5 | 66.3 |

| 3″ x 3″ x 1″ | 80 x 80 x 25 | 88.9 x 88.9 x 33.4 | 50.8 | 67.6 |

| 3″ x 3″ x 1-1/4″ | 80 x 80 x 32 | 88.9 x 88.9 x 42.2 | 55.1 | 69.6 |

| 3″ x 3″ x 1-1/2″ | 80 x 80 x 40 | 88.9 x 88.9 x 48.3 | 58.2 | 71.1 |

| 3″ x 3″ x 2″ | 80 x 80 x 50 | 88.9 x 88.9 x 60.3 | 64 | 73.4 |

| 3″ x 3″ x 2-1/2″ | 80 x 80 x 65 | 88.9 x 88.9 x 73.0 | 71.9 | 76 |

| 4″ x 4″ x 1/2″ | 100 x 100 x 15 | 114.3 x 114.3 x 21.3 | 50 | 79 |

| 4″ x 4″ x 3/4″ | 100 x 100 x 20 | 114.3 x 114.3 x 26.7 | 53 | 79 |

| 4″ x 4″ x 1″ | 100 x 100 x 25 | 114.3 x 114.3 x 33.4 | 56 | 82 |

| 4″ x 4″ x 1-1/4″ | 100 x 100 x 32 | 114.3 x 114.3 x 42.2 | 60 | 84 |

| 4″ x 4″ x 1-1/2″ | 100 x 100 x 40 | 114.3 x 114.3 x 48.3 | 63.8 | 84.3 |

| 4″ x 4″ x 2″ | 100 x 100 x 50 | 114.3 x 114.3 x 60.3 | 69.6 | 86.6 |

| 4″ x 4″ x 2-1/2″ | 100 x 100 x 65 | 114.3 x 114.3 x 73.0 | 77.5 | 89.2 |

| 4″ x 4″ x 3″ | 100 x 100 x 80 | 114.3 x 114.3 x 88.9 | 83.8 | 91.4 |

| 1/2” x 1/2” x 3/8” | 15 x 15 x 10 | 21.3 x 21.3 x 17.1 | 30.2 | 30.2 |

| 3/4” x 3/4” x 1/2” | 20 x 20 x 15 | 26.7 x 26.7 x 21.3 | 33.3 | 35.1 |

| 1” x 1” x 1/2” | 25 x 25 x 15 | 33.4 x 33.4 x 21.3 | 36.6 | 38.1 |

| 1 x 1 x 3/4” | 25 x 25 x 20 | 33.4 x 33.4 x 26.7 | 38.1 | 39.6 |

| 1-1/4” x 1-1/4” x 1/2” | 32 x 32 x 15 | 42.2 x 42.2 x 21.3 | 38.1 | 42.9 |

| 1-1/4” x 1-1/4” x 3/4” | 32 x 32 x 20 | 42.2 x 42.2 x 26.7 | 41.4 | 44.5 |

| 1-1/4” x 1-1/4” x 1” | 32 x 32 x 25 | 42.2 x 42.2 x 33.4 | 44.5 | 46 |

| 1-1/2” x 1-1/2” x 1/2” | 40 x 40 x 15 | 48.3 x 48.3 x 21.3 | 41.4 | 46 |

| 1-1/2” x 1-1/2” x 3/4” | 40 x 40 x 20 | 48.3 x 48.3 x 26.7 | 42.9 | 47.6 |

| 1-1/2” x 1-1/2” x 1” | 40 x 40 x 25 | 48.3 x 48.3 x 33.4 | 46 | 50.8 |

| 1-1/2” x 1-1/2” x 1-1/4” | 40 x 40 x 32 | 48.3 x 48.3 x 42.2 | 50.8 | 52.3 |

| 2” x 2” x 1/2” | 50 x 50 x 15 | 60.3 x 60.3 x 21.3 | 44.5 | 52.3 |

| 2” x 2” x 3/4” | 50 x 50 x 20 | 60.3 x 60.3 x 26.7 | 46 | 54.1 |

| 2” x 2” x 1” | 50 x 50 x 25 | 60.3 x 60.3 x 33.4 | 50.8 | 57.2 |

| 2” x 2” x 1-1/4” | 50 x 50 x 32 | 60.3 x 60.3 x 42.2 | 54.1 | 58.7 |

| 2” x 2” x 1-1/2” | 50 x 50 x 40 | 60.3 x 60.3 x 48.3 | 57.2 | 60.5 |

| 2-1/2” x 2-1/2” x 2” | 65 x 65 x 50 | 73.0 x 73.0 x 60.3 | 68.3 | 70 |

| 3” x 3” x 2” | 80 x 80 x 50 | 88.9 x 88.9 x 60.3 | 71.4 | 79.5 |

| 4” x 4” x 2-1/2” | 100 x 100 x 65 | 114.3 x 114.3 x 73.0 | 94 | 101.5 |

| 4” x 4” x 3” | 100 x 100 x 80 | 114.3 x 114.3 x 88.9 | 101.5 | 108 |

application

- System Intelligent Flow Distribution: Fire protection/HVAC main pipeline diameter reduction branches, large diameter pipes (e.g., 4“) transitioning to smaller branch pipes (e.g., 1”), precisely matching equipment interfaces.

- Equipment Stepwise Power Supply: Air compressor units, multi-stage pump rooms, achieve stepwise flow distribution through diameter reduction structures (e.g., 4“×4”×3″ three-way fittings optimize energy consumption).

- Space-Saving Retrofits: Building pipe shafts and ship engine rooms utilize compact designs (e.g., 1“ × 1” × 1/4″ with a center distance of 28.2 mm) to resolve pipe misalignment issues.

- High-pressure safety diversion: Class 300 grade for hydraulic system branches (e.g., 2“ × 2” × 1″ with a pressure rating of 1500 psi), capable of withstanding 2000 psi impact.

- Upgrading of old pipelines: Municipal water supply pipelines with newly added small-diameter branches (e.g., 6“ main pipe connected to a 2” branch pipe), eliminating the need for pipe cutting during renovation.

advantages

- Versatile Flow Master:

- Over 50 size combinations (e.g., 4“ × 4” × 3“ to 1/2” × 1/2“ × 3/8”), covering all industrial applications;

- Smooth inner wall transitions, branch pipe pressure drop <8%, outperforming welded size transition solutions.

- Dual Pressure Rating All-Round Protection:

- Class 150: General-purpose, 300 psi pressure rating, -29°C to 66°C temperature range;

- Class 300: High-pressure specialized (e.g., 3“×3”×2″ with a 1500 psi pressure rating), 90% increased safety margin.

- Triple-barrier structure:

- Forged cast iron (ASTM A197) one-piece casting, with a 60% improvement in water hammer resistance;

- NPT threaded three-way self-sealing, UL/FM certified with zero leakage;

- Hot-dip galvanized coating >85μm, salt spray resistance >1200 hours.

- Space-Saving Design:

- Small-diameter reducer tees (e.g., 1“×1”×1/4″) save 40% installation space;

- Optimized branch center distance (e.g., 4“×4”×3″ with only 83.8mm), reducing bracket modifications.

- 3-minute rapid installation: Threaded direct screw-in without tools, 8 times faster than flange connections.

packing

- Ultimate Interface Protection:

- Each threaded port is coated with long-lasting anti-rust grease, and protected with a double layer of silicone caps and heat-shrinkable film;

- Special protection for reducer interfaces: thickened EPE foam rings prevent impact and deformation.

- Smart Graded Packaging:

- ≤2 inches: 15 pieces per box, honeycomb paper tray compartments + variable diameter combination labels (e.g., “2”×2“×1” → DN50×50×25″);

- >2 inches: Single-piece suspended steel frame box, with pressure rating color codes printed on the box (blue = 150/red = 300).

- Revolutionary solution for large items:

- For three-way fittings over 4 inches, use a disassemblable steel structure box with casters and brakes on the bottom;

- Built-in NFC chip for scanning to access installation videos and pressure parameters.

- Dual safety measures:

- Product body laser-engraved with pressure rating and size specifications (e.g., “CL300 4”×4“×3”);

- Outer box labeled with three-way flow direction arrows, with red warning text “Size-changing branch pipe.”

Available size

| SIZE | A | B | ||

| INCH | DN | MM | MM | MM |

| 3/4″ x 3/4″ x 1/2″ | 20 x 20 x 15 | 26.7 x 26.7 x 21.3 | 30.5 | 31 |

| 1″ x 1″ x 1/4″ | 25 x 25 x 8 | 33.4 x 33.4 x 13.7 | 28.2 | 31 |

| 1″ x 1″ x 3/8″ | 25 x 25 x 10 | 33.4 x 33.4 x 17.1 | 30 | 32.3 |

| 1″ x 1″ x 1/2″ | 25 x 25 x 15 | 33.4 x 33.4 x 21.3 | 32 | 35.5 |

| 1″ x 1″ x 3/4″ | 25 x 25 x 20 | 33.4 x 33.4 x 26.7 | 34.8 | 36.8 |

| 1-1/4″ x 1-1/4″ x 3/8″ | 32 x 32 x 10 | 42.2 x 42.2 x 17.1 | 32 | 36.6 |

| 1-1/4″ x 1-1/4″ x 1/2″ | 32 x 32 x 15 | 42.2 x 42.2 x 21.3 | 34 | 38.9 |

| 1-1/4″ x 1-1/4″ x 3/4″ | 32 x 32 x 20 | 42.2 x 42.2 x 26.7 | 36.8 | 41.2 |

| 1-1/4″ x 1-1/4″ x 1″ | 32 x 32 x 25 | 42.2 x 42.2 x 33.4 | 40.1 | 42.4 |

| 1-1/2″ x 1-1/2″ x 1/2″ | 40 x 40 x 15 | 48.3 x 48.3 x 21.3 | 35.8 | 42.2 |

| 1-1/2″ x 1-1/2″ x 3/4″ | 40 x 40 x 20 | 48.3 x 48.3 x 26.7 | 38.6 | 44.5 |

| 1-1/2″ x 1-1/2″ x 1″ | 40 x 40 x 25 | 48.3 x 48.3 x 33.4 | 41.9 | 45.7 |

| 1-1/2″ x 1-1/2″ x 1-1/4″ | 40 x 40 x 32 | 48.3 x 48.3 x 42.2 | 46.2 | 47.8 |

| 2″ x 2″ x 1/2″ | 50 x 50 x 15 | 60.3 x 60.3 x 21.3 | 37.9 | 47.8 |

| 2″ x 2″ x 3/4″ | 50 x 50 x 20 | 60.3 x 60.3 x 26.7 | 40.6 | 50 |

| 2″ x 2″ x 1″ | 50 x 50 x 25 | 60.3 x 60.3 x 33.4 | 43.9 | 51.3 |

| 2″ x 2″ x 1-1/4″ | 50 x 50 x 32 | 60.3 x 60.3 x 42.2 | 48.3 | 53.3 |

| 2″ x 2″ x 1-1/2″ | 50 x 50 x 40 | 60.3 x 60.3 x 48.3 | 51.3 | 54.9 |

| 2-1/2″ x 2-1/2″ x 1/2″ | 65 x 65 x 15 | 73.0 x 73.0 x 21.3 | 41 | 57 |

| 2-1/2″ x 2-1/2″ x 3/4″ | 65 x 65 x 20 | 73.0 x 73.0 x 26.7 | 44.2 | 58.9 |

| 2-1/2″ x 2-1/2″ x 1″ | 65 x 65 x 25 | 73.0 x 73.0 x 33.4 | 47.5 | 60.2 |

| 2-1/2″ x 2-1/2″ x 1-1/4″ | 65 x 65 x 32 | 73.0 x 73.0 x 42.2 | 51.8 | 62.2 |

| 2-1/2″ x 2-1/2″ x 1-1/2″ | 65 x 65 x 40 | 73.0 x 73.0 x 48.3 | 54.9 | 63.8 |

| 2-1/2″ x 2-1/2″ x 2″ | 65 x 65 x 50 | 73.0 x 73.0 x 60.3 | 60.7 | 66 |

| 3″ x 3″ x 1/2″ | 80 x 80 x 15 | 88.9 x 88.9 x 21.3 | 42 | 64 |

| 3″ x 3″ x 3/4″ | 80 x 80 x 20 | 88.9 x 88.9 x 26.7 | 47.5 | 66.3 |

| 3″ x 3″ x 1″ | 80 x 80 x 25 | 88.9 x 88.9 x 33.4 | 50.8 | 67.6 |

| 3″ x 3″ x 1-1/4″ | 80 x 80 x 32 | 88.9 x 88.9 x 42.2 | 55.1 | 69.6 |

| 3″ x 3″ x 1-1/2″ | 80 x 80 x 40 | 88.9 x 88.9 x 48.3 | 58.2 | 71.1 |

| 3″ x 3″ x 2″ | 80 x 80 x 50 | 88.9 x 88.9 x 60.3 | 64 | 73.4 |

| 3″ x 3″ x 2-1/2″ | 80 x 80 x 65 | 88.9 x 88.9 x 73.0 | 71.9 | 76 |

| 4″ x 4″ x 1/2″ | 100 x 100 x 15 | 114.3 x 114.3 x 21.3 | 50 | 79 |

| 4″ x 4″ x 3/4″ | 100 x 100 x 20 | 114.3 x 114.3 x 26.7 | 53 | 79 |

| 4″ x 4″ x 1″ | 100 x 100 x 25 | 114.3 x 114.3 x 33.4 | 56 | 82 |

| 4″ x 4″ x 1-1/4″ | 100 x 100 x 32 | 114.3 x 114.3 x 42.2 | 60 | 84 |

| 4″ x 4″ x 1-1/2″ | 100 x 100 x 40 | 114.3 x 114.3 x 48.3 | 63.8 | 84.3 |

| 4″ x 4″ x 2″ | 100 x 100 x 50 | 114.3 x 114.3 x 60.3 | 69.6 | 86.6 |

| 4″ x 4″ x 2-1/2″ | 100 x 100 x 65 | 114.3 x 114.3 x 73.0 | 77.5 | 89.2 |

| 4″ x 4″ x 3″ | 100 x 100 x 80 | 114.3 x 114.3 x 88.9 | 83.8 | 91.4 |

| 1/2” x 1/2” x 3/8” | 15 x 15 x 10 | 21.3 x 21.3 x 17.1 | 30.2 | 30.2 |

| 3/4” x 3/4” x 1/2” | 20 x 20 x 15 | 26.7 x 26.7 x 21.3 | 33.3 | 35.1 |

| 1” x 1” x 1/2” | 25 x 25 x 15 | 33.4 x 33.4 x 21.3 | 36.6 | 38.1 |

| 1 x 1 x 3/4” | 25 x 25 x 20 | 33.4 x 33.4 x 26.7 | 38.1 | 39.6 |

| 1-1/4” x 1-1/4” x 1/2” | 32 x 32 x 15 | 42.2 x 42.2 x 21.3 | 38.1 | 42.9 |

| 1-1/4” x 1-1/4” x 3/4” | 32 x 32 x 20 | 42.2 x 42.2 x 26.7 | 41.4 | 44.5 |

| 1-1/4” x 1-1/4” x 1” | 32 x 32 x 25 | 42.2 x 42.2 x 33.4 | 44.5 | 46 |

| 1-1/2” x 1-1/2” x 1/2” | 40 x 40 x 15 | 48.3 x 48.3 x 21.3 | 41.4 | 46 |

| 1-1/2” x 1-1/2” x 3/4” | 40 x 40 x 20 | 48.3 x 48.3 x 26.7 | 42.9 | 47.6 |

| 1-1/2” x 1-1/2” x 1” | 40 x 40 x 25 | 48.3 x 48.3 x 33.4 | 46 | 50.8 |

| 1-1/2” x 1-1/2” x 1-1/4” | 40 x 40 x 32 | 48.3 x 48.3 x 42.2 | 50.8 | 52.3 |

| 2” x 2” x 1/2” | 50 x 50 x 15 | 60.3 x 60.3 x 21.3 | 44.5 | 52.3 |

| 2” x 2” x 3/4” | 50 x 50 x 20 | 60.3 x 60.3 x 26.7 | 46 | 54.1 |

| 2” x 2” x 1” | 50 x 50 x 25 | 60.3 x 60.3 x 33.4 | 50.8 | 57.2 |

| 2” x 2” x 1-1/4” | 50 x 50 x 32 | 60.3 x 60.3 x 42.2 | 54.1 | 58.7 |

| 2” x 2” x 1-1/2” | 50 x 50 x 40 | 60.3 x 60.3 x 48.3 | 57.2 | 60.5 |

| 2-1/2” x 2-1/2” x 2” | 65 x 65 x 50 | 73.0 x 73.0 x 60.3 | 68.3 | 70 |

| 3” x 3” x 2” | 80 x 80 x 50 | 88.9 x 88.9 x 60.3 | 71.4 | 79.5 |

| 4” x 4” x 2-1/2” | 100 x 100 x 65 | 114.3 x 114.3 x 73.0 | 94 | 101.5 |

| 4” x 4” x 3” | 100 x 100 x 80 | 114.3 x 114.3 x 88.9 | 101.5 | 108 |

- System Intelligent Flow Distribution: Fire protection/HVAC main pipeline diameter reduction branches, large diameter pipes (e.g., 4“) transitioning to smaller branch pipes (e.g., 1”), precisely matching equipment interfaces.

- Equipment Stepwise Power Supply: Air compressor units, multi-stage pump rooms, achieve stepwise flow distribution through diameter reduction structures (e.g., 4“×4”×3″ three-way fittings optimize energy consumption).

- Space-Saving Retrofits: Building pipe shafts and ship engine rooms utilize compact designs (e.g., 1“ × 1” × 1/4″ with a center distance of 28.2 mm) to resolve pipe misalignment issues.

- High-pressure safety diversion: Class 300 grade for hydraulic system branches (e.g., 2“ × 2” × 1″ with a pressure rating of 1500 psi), capable of withstanding 2000 psi impact.

- Upgrading of old pipelines: Municipal water supply pipelines with newly added small-diameter branches (e.g., 6“ main pipe connected to a 2” branch pipe), eliminating the need for pipe cutting during renovation.

- Versatile Flow Master:

- Over 50 size combinations (e.g., 4“ × 4” × 3“ to 1/2” × 1/2“ × 3/8”), covering all industrial applications;

- Smooth inner wall transitions, branch pipe pressure drop <8%, outperforming welded size transition solutions.

- Dual Pressure Rating All-Round Protection:

- Class 150: General-purpose, 300 psi pressure rating, -29°C to 66°C temperature range;

- Class 300: High-pressure specialized (e.g., 3“×3”×2″ with a 1500 psi pressure rating), 90% increased safety margin.

- Triple-barrier structure:

- Forged cast iron (ASTM A197) one-piece casting, with a 60% improvement in water hammer resistance;

- NPT threaded three-way self-sealing, UL/FM certified with zero leakage;

- Hot-dip galvanized coating >85μm, salt spray resistance >1200 hours.

- Space-Saving Design:

- Small-diameter reducer tees (e.g., 1“×1”×1/4″) save 40% installation space;

- Optimized branch center distance (e.g., 4“×4”×3″ with only 83.8mm), reducing bracket modifications.

- 3-minute rapid installation: Threaded direct screw-in without tools, 8 times faster than flange connections.

- Ultimate Interface Protection:

- Each threaded port is coated with long-lasting anti-rust grease, and protected with a double layer of silicone caps and heat-shrinkable film;

- Special protection for reducer interfaces: thickened EPE foam rings prevent impact and deformation.

- Smart Graded Packaging:

- ≤2 inches: 15 pieces per box, honeycomb paper tray compartments + variable diameter combination labels (e.g., “2”×2“×1” → DN50×50×25″);

- >2 inches: Single-piece suspended steel frame box, with pressure rating color codes printed on the box (blue = 150/red = 300).

- Revolutionary solution for large items:

- For three-way fittings over 4 inches, use a disassemblable steel structure box with casters and brakes on the bottom;

- Built-in NFC chip for scanning to access installation videos and pressure parameters.

- Dual safety measures:

- Product body laser-engraved with pressure rating and size specifications (e.g., “CL300 4”×4“×3”);

- Outer box labeled with three-way flow direction arrows, with red warning text “Size-changing branch pipe.”

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.