HOT PRODUCTS TAGS

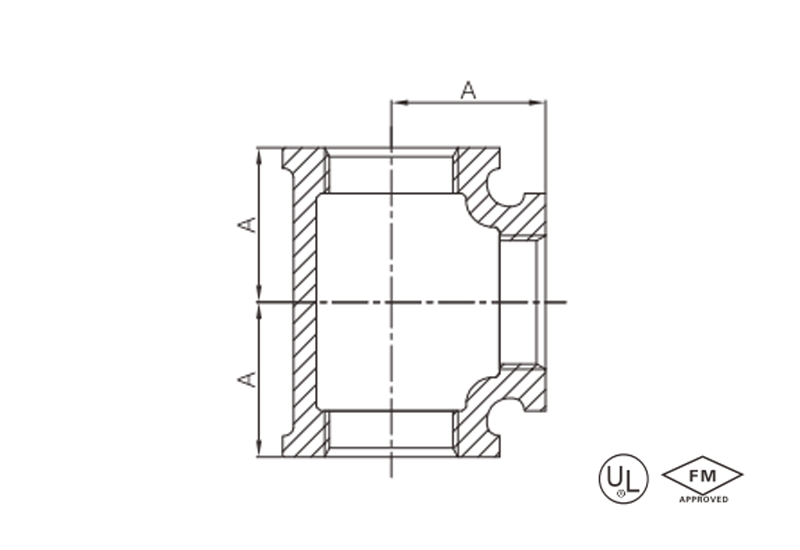

Malleable iron straight tee

·Standard: ANSI/ASME B16.3

UL/FM

·Material: Malleable iron ASTM A197

·Thread: NPT

·W. pressure: Class 150, 300 psi (-29°C to 66°C)

Class 300, 1000 / 1500 / 2000 psi

(-29°C to 66°C)

·Surface: Black iron / hot dip galvanized

·Size Range: 1/2″ —6″ (Class 150)

1/4″—4″ (Class 300)

description

Malleable iron straight tee, integrally formed, with firm connection, pressure and corrosion resistance, and stable and efficient flow division.

Specification

Available size

SIZE | A | ||

INCH | DN | MM | MM |

1/2″ | 15 | 21.3 | 28.5 |

3/4″ | 20 | 26.7 | 33.3 |

1″ | 25 | 33.4 | 38.1 |

1-1/4″ | 32 | 42.2 | 44.5 |

1-1/2″ | 40 | 48.3 | 49.3 |

2″ | 50 | 60.3 | 57.2 |

2-1/2″ | 65 | 73 | 68.6 |

3″ | 80 | 88.9 | 78.2 |

4″ | 100 | 114.3 | 96.3 |

6” | 150 | 168.3 | 130.3 |

1/4” | 8 | 13.7 | 23.9 |

3/8” | 10 | 17.1 | 26.9 |

1/2” | 15 | 21.3 | 31.8 |

3/4” | 20 | 26.7 | 35.6 |

1” | 25 | 33.4 | 41.4 |

1-1/4” | 32 | 42.2 | 49.3 |

1-1/2” | 40 | 48.3 | 54.1 |

2” | 50 | 60.3 | 63.5 |

2-1/2” | 65 | 73 | 74.7 |

3” | 80 | 88.9 | 85.9 |

4” | 100 | 114.3 | 114 |

application

- Main pipeline efficient diversion: Fire protection/HVAC main pipelines with equal-diameter branches, flow distribution error <5%, preventing system imbalance.

- Equipment cluster connection: Pump room multi-pump parallel connection, air compressor units, three-way interfaces reduce welding joints by 40%, eliminating leakage risks.

- Compact Space Piping Layout: In building pipe shafts and ship engine rooms, short center distance design (e.g., 1/2″ with only 28.5mm) saves space.

- High-Pressure Safety System: Class 300-rated for hydraulic stations and steam pipelines, withstands 2000psi impact without bursting.

- System Rapid Expansion: When adding new branches to municipal pipelines, threaded direct connection is possible without interrupting the main pipeline.

advantages

- Dual pressure rating for comprehensive coverage:

- Class 150: Economical and versatile, with a pressure rating of 300 psi and a temperature range of -29°C to 66°C;

- Class 300: High-pressure specific (e.g., 2″ with a pressure rating of 1500 psi), with an 80% increase in safety redundancy.

- Triple-reinforced structure:

- Forged cast iron (ASTM A197) one-piece casting, with water hammer impact resistance 50% higher than ordinary cast iron;

- NPT threaded three-way sealing, UL/FM certified with zero leakage;

- Hot-dip galvanized coating >80μm, salt spray resistance >1000 hours.

- Zero flow loss: Equal-diameter design with branch pressure drop <3%, outperforming reducer tees.

- Minute-level installation: Threaded direct screw-on without tools, 10 times faster than flange connections.

- Full-size compatibility: 1/4“-6” covers all scenarios from instrument microtubes to industrial mainlines.

packing

- Threaded Armor Protection:

- Each port is filled with food-grade anti-rust oil, sealed with a silicone cap and heat-shrinkable film;

- The main body is wrapped in pearl cotton and embedded in a high-density EPS mold to prevent collision and breakage.

- Smart Graded Packaging:

- ≤2 inches: 20 pieces per box, honeycomb paper trays with dividers + desiccant, outer box printed with pressure rating color codes (blue = 150/red = 300);

- >2 inches: Single-piece suspended steel frame box, three-way branch pipes fitted with EVA protective caps, box body with ventilation holes for easy forklift handling.

- Revolutionary Solution for Large Items:

- 4“-6” three-way fittings use disassemblable steel structure boxes with anti-slip rubber wheels on the bottom;

- built-in NFC chip for scanning to obtain installation torque and pressure parameters.

- Error-proofing traceability system:

- Product body laser-engraved with “CL150/300” markings;

- outer box labeled with three-way flow direction arrows and “equal-diameter diversion” warning text.

Available size

SIZE | A | ||

INCH | DN | MM | MM |

1/2″ | 15 | 21.3 | 28.5 |

3/4″ | 20 | 26.7 | 33.3 |

1″ | 25 | 33.4 | 38.1 |

1-1/4″ | 32 | 42.2 | 44.5 |

1-1/2″ | 40 | 48.3 | 49.3 |

2″ | 50 | 60.3 | 57.2 |

2-1/2″ | 65 | 73 | 68.6 |

3″ | 80 | 88.9 | 78.2 |

4″ | 100 | 114.3 | 96.3 |

6” | 150 | 168.3 | 130.3 |

1/4” | 8 | 13.7 | 23.9 |

3/8” | 10 | 17.1 | 26.9 |

1/2” | 15 | 21.3 | 31.8 |

3/4” | 20 | 26.7 | 35.6 |

1” | 25 | 33.4 | 41.4 |

1-1/4” | 32 | 42.2 | 49.3 |

1-1/2” | 40 | 48.3 | 54.1 |

2” | 50 | 60.3 | 63.5 |

2-1/2” | 65 | 73 | 74.7 |

3” | 80 | 88.9 | 85.9 |

4” | 100 | 114.3 | 114 |

- Main pipeline efficient diversion: Fire protection/HVAC main pipelines with equal-diameter branches, flow distribution error <5%, preventing system imbalance.

- Equipment cluster connection: Pump room multi-pump parallel connection, air compressor units, three-way interfaces reduce welding joints by 40%, eliminating leakage risks.

- Compact Space Piping Layout: In building pipe shafts and ship engine rooms, short center distance design (e.g., 1/2″ with only 28.5mm) saves space.

- High-Pressure Safety System: Class 300-rated for hydraulic stations and steam pipelines, withstands 2000psi impact without bursting.

- System Rapid Expansion: When adding new branches to municipal pipelines, threaded direct connection is possible without interrupting the main pipeline.

- Dual pressure rating for comprehensive coverage:

- Class 150: Economical and versatile, with a pressure rating of 300 psi and a temperature range of -29°C to 66°C;

- Class 300: High-pressure specific (e.g., 2″ with a pressure rating of 1500 psi), with an 80% increase in safety redundancy.

- Triple-reinforced structure:

- Forged cast iron (ASTM A197) one-piece casting, with water hammer impact resistance 50% higher than ordinary cast iron;

- NPT threaded three-way sealing, UL/FM certified with zero leakage;

- Hot-dip galvanized coating >80μm, salt spray resistance >1000 hours.

- Zero flow loss: Equal-diameter design with branch pressure drop <3%, outperforming reducer tees.

- Minute-level installation: Threaded direct screw-on without tools, 10 times faster than flange connections.

- Full-size compatibility: 1/4“-6” covers all scenarios from instrument microtubes to industrial mainlines.

- Threaded Armor Protection:

- Each port is filled with food-grade anti-rust oil, sealed with a silicone cap and heat-shrinkable film;

- The main body is wrapped in pearl cotton and embedded in a high-density EPS mold to prevent collision and breakage.

- Smart Graded Packaging:

- ≤2 inches: 20 pieces per box, honeycomb paper trays with dividers + desiccant, outer box printed with pressure rating color codes (blue = 150/red = 300);

- >2 inches: Single-piece suspended steel frame box, three-way branch pipes fitted with EVA protective caps, box body with ventilation holes for easy forklift handling.

- Revolutionary Solution for Large Items:

- 4“-6” three-way fittings use disassemblable steel structure boxes with anti-slip rubber wheels on the bottom;

- built-in NFC chip for scanning to obtain installation torque and pressure parameters.

- Error-proofing traceability system:

- Product body laser-engraved with “CL150/300” markings;

- outer box labeled with three-way flow direction arrows and “equal-diameter diversion” warning text.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.