HOT PRODUCTS TAGS

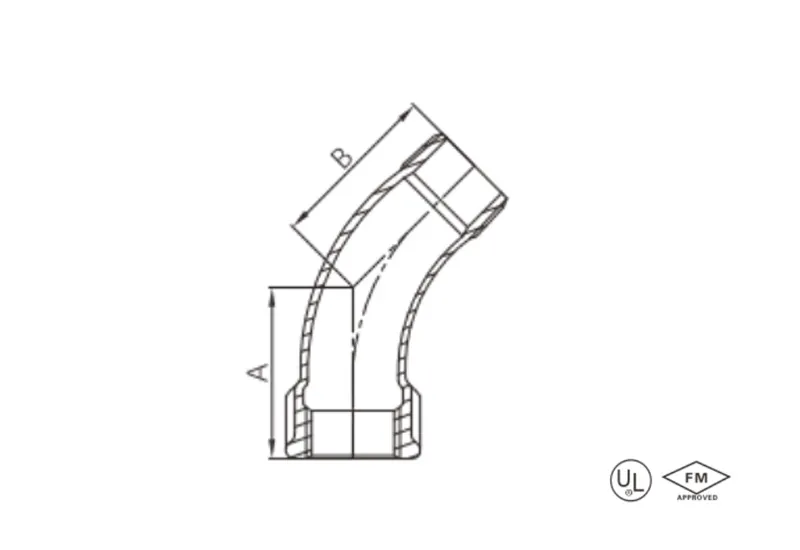

Malleable cast iron 45° male and female long sweep bend

·Standard: ISO 49 / EN 10242

UL/FM

·Material: BS EN 1562, EN-GJMB-350-10

·Thread: BSPT

·W. pressure: 20 ~ 25 bar, ≤ PN25

·Surface: Black iron / hot dip galvanized

·Size Range: 1/4″ —4″

description

Malleable cast iron 45° male and female long sweep bend, quick socket connection, gentle arc reduces resistance, sturdy and suitable for various pipelines.

Specification

Available size

| SIZE | A | B | ||

| INCH | DN | MM | MM | MM |

| 1/4″ | 8 | 13.5 | 26 | 21 |

| 3/8″ | 10 | 17.2 | 30 | 24 |

| 1/2″ | 15 | 21.3 | 36 | 30 |

| 3/4″ | 20 | 26.9 | 43 | 36 |

| 1″ | 25 | 33.7 | 51 | 42 |

| 1-1/4″ | 32 | 42.4 | 64 | 54 |

| 1-1/2″ | 40 | 48.3 | 68 | 58 |

| 2″ | 50 | 60.3 | 81 | 70 |

| 2-1/2″ | 65 | 76.1 | 99 | 86 |

| 3″ | 80 | 88.9 | 113 | 100 |

| 4″ | 100 | 114.3 | 142 | 126 |

application

- Compact Space Pipe System: Integrated internal and external threads enable quick installation of 45° turns inside equipment cabinets.

- Fire Protection Pipe Network Renovation Project: UL-certified structure ensures low flow resistance angle adjustment for sprinkler systems.

- Ship Engine Room Piping: Angle conversion solutions for fuel/cooling water systems in space-constrained areas.

- Industrial Equipment Integration: Space-optimized quick-turn connections for compressor inlet and outlet pipelines.

- Energy Transmission Network: Gradual angle adaptation solutions for oil and gas pipeline inspection ports.

- Agricultural irrigation hubs: Quick connections for water-saving angle adjustments on main pipelines at pump stations.

- Chemical process equipment: Sealed angle conversion connections for pipelines around reactors

- Mining equipment pipelines: Anti-loosening angle adjustment solutions for high-vibration conditions.

advantages

- Creative connection design: The combination of internal thread and external thread completes the quick installation of a single end.

- Streamlined fluid dynamic: one of the least turning flow obstructed long radius designs: 45° – less flow resistance.

- Proven Base: Passed industrial wear testing of base material. Long-term corrosion protection system: hot-dip galvanized coating offers fully-sutained corrosion protection.

- Save Space Efficiently: 45° turning angle improves the utilization of complicated area configurations.

- Quick Easy Install: Single Ended quick-connect reduces installation time by 50 %.

- Materiality: Takes advantage of a long radius design to mitigate stress con-centration.

packing

- Protective covering of threads in composite: Engineering plastic screw caps for inner and outer threaded ends.

- Built-in Curved Surface Cushioning System : EPE pearl cotton direct bonding to 45°bent tube curve surface.

- Processing: vapor-phase corhiding (VCI) anti-rust film vacuum packaging.

- Packaging: Steel tape reinforcement, fumigated wooden box fixed (according to international phytosanitary standards).

- Application of Authority Traceability Accession: QR code is mailed to the box body for authority certification and its parameter specs.

- Anti-Throwing Design: Angle and fixed frame in the box to avoid shaking when transport.

Available size

SIZE | A | B | ||

INCH | DN | MM | MM | MM |

1/4″ | 8 | 13.5 | 26 | 21 |

3/8″ | 10 | 17.2 | 30 | 24 |

1/2″ | 15 | 21.3 | 36 | 30 |

3/4″ | 20 | 26.9 | 43 | 36 |

1″ | 25 | 33.7 | 51 | 42 |

1-1/4″ | 32 | 42.4 | 64 | 54 |

1-1/2″ | 40 | 48.3 | 68 | 58 |

2″ | 50 | 60.3 | 81 | 70 |

2-1/2″ | 65 | 76.1 | 99 | 86 |

3″ | 80 | 88.9 | 113 | 100 |

4″ | 100 | 114.3 | 142 | 126 |

- Compact Space Pipe System: Integrated internal and external threads enable quick installation of 45° turns inside equipment cabinets.

- Fire Protection Pipe Network Renovation Project: UL-certified structure ensures low flow resistance angle adjustment for sprinkler systems.

- Ship Engine Room Piping: Angle conversion solutions for fuel/cooling water systems in space-constrained areas.

- Industrial Equipment Integration: Space-optimized quick-turn connections for compressor inlet and outlet pipelines.

- Energy Transmission Network: Gradual angle adaptation solutions for oil and gas pipeline inspection ports.

- Agricultural irrigation hubs: Quick connections for water-saving angle adjustments on main pipelines at pump stations.

- Chemical process equipment: Sealed angle conversion connections for pipelines around reactors

- Mining equipment pipelines: Anti-loosening angle adjustment solutions for high-vibration conditions.

- Creative connection design: The combination of internal thread and external thread completes the quick installation of a single end.

- Streamlined fluid dynamic: one of the least turning flow obstructed long radius designs: 45° – less flow resistance.

- Proven Base: Passed industrial wear testing of base material. Long-term corrosion protection system: hot-dip galvanized coating offers fully-sutained corrosion protection.

- Save Space Efficiently: 45° turning angle improves the utilization of complicated area configurations.

- Quick Easy Install: Single Ended quick-connect reduces installation time by 50 %.

- Materiality: Takes advantage of a long radius design to mitigate stress con-centration.

- Protective covering of threads in composite: Engineering plastic screw caps for inner and outer threaded ends.

- Built-in Curved Surface Cushioning System : EPE pearl cotton direct bonding to 45°bent tube curve surface.

- Processing: vapor-phase corhiding (VCI) anti-rust film vacuum packaging.

- Packaging: Steel tape reinforcement, fumigated wooden box fixed (according to international phytosanitary standards).

- Application of Authority Traceability Accession: QR code is mailed to the box body for authority certification and its parameter specs.

- Anti-Throwing Design: Angle and fixed frame in the box to avoid shaking when transport.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.