HOT PRODUCTS TAGS

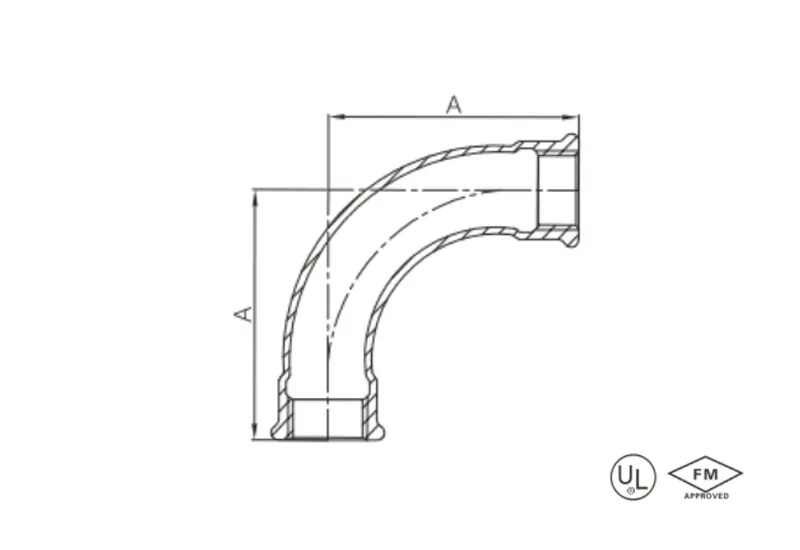

Malleable cast iron 90° long sweep bend

·Standard: ISO 49 / EN 10242

UL/FM

·Material: BS EN 1562, EN-GJMB-350-10

·Thread: BSPT

·W. pressure: 20 ~ 25 bar, ≤ PN25

·Surface: Black iron / hot dip galvanized

·Size Range: 1/4″ —4″

description

Malleable cast iron 90° long sweep bend, large arc reduces flow resistance, pressure-resistant and wear-resistant, fits complex pipelines.

Specification

Available size

SIZE | A | ||

INCH | DN | MM | MM |

1/4″ | 8 | 13.5 | 40 |

3/8″ | 10 | 17.2 | 48 |

1/2″ | 15 | 21.3 | 55 |

3/4″ | 20 | 26.9 | 69 |

1″ | 25 | 33.7 | 85 |

1-1/4″ | 32 | 42.4 | 105 |

1-1/2″ | 40 | 48.3 | 116 |

2″ | 50 | 60.3 | 140 |

2-1/2″ | 65 | 76.1 | 176 |

3″ | 80 | 88.9 | 205 |

4″ | 100 | 114.3 | 260 |

NOTE:NSF 61 certificate is available for M4402 ~ M4411, except M4401.

application

- Chemical process systems: Long-radius elbows reduce pressure loss in the transportation of high-viscosity media.

- Fire protection network layout: UL-certified structures ensure high-pressure, low-resistance turns in sprinkler systems.

- Ship power piping: Large-radius turns for fuel/cooling water connections in engine rooms.

- Energy transportation networks: Low-resistance, long-distance turn solutions for oil and gas pipelines.

- Municipal water supply renovation: Main pipeline network turns with connections to reduce water hammer effects.

- Industrial equipment integration: Low-turbulence turns for compressor inlet/outlet pipelines.

- Agricultural irrigation systems: Large-radius water-saving turns for high-pressure main pipelines at pump stations.

- Mining slurry transportation: High wear resistance to withstand wear in slurry pipeline turns.

advantages

- Hydrodynamics optimization: Large radius design significantly reduces flow resistance and pressure loss.

- High-pressure structure strengthening: The malleable cast iron base can meet the requirements of industrial pipeline pressure.

- Wear resistance: To be used with particulate media and rate to be tested according to the ISO 6509 wear resistance test.

- Durable corrosion resistance: Hot-dip galvanized coating gives the highest possible level of corrosion protection.

- Safety certification claim:

- Relevant specifications meet the drinking water contact rules (NSF 61).

- Resistance to extreme temperatures (-30°C to 120°C).

- Complete specification coverage: DN8-DN100 meets the needs of micro-pipelines to trunks.

packing

- Thread Protection: Dual end cap engineering plastic screw nested protection.

- Curved Surface Buffer Design: Fixed with EPE pearl cotton to bend the curved pipe shape.

- How to process the anti-rust film: Add VCI vapor phase rust inhibitor and vacuum seal.

- Integration of traceability information: packaging QR code with certificate, curvature parameters.

- The packing material with inner container of curved reinforcement design, making transportation without moving.

Available size

SIZE | A | ||

INCH | DN | MM | MM |

1/4″ | 8 | 13.5 | 40 |

3/8″ | 10 | 17.2 | 48 |

1/2″ | 15 | 21.3 | 55 |

3/4″ | 20 | 26.9 | 69 |

1″ | 25 | 33.7 | 85 |

1-1/4″ | 32 | 42.4 | 105 |

1-1/2″ | 40 | 48.3 | 116 |

2″ | 50 | 60.3 | 140 |

2-1/2″ | 65 | 76.1 | 176 |

3″ | 80 | 88.9 | 205 |

4″ | 100 | 114.3 | 260 |

NOTE:NSF 61 certificate is available for M4402 ~ M4411, except M4401.

- Chemical process systems: Long-radius elbows reduce pressure loss in the transportation of high-viscosity media.

- Fire protection network layout: UL-certified structures ensure high-pressure, low-resistance turns in sprinkler systems.

- Ship power piping: Large-radius turns for fuel/cooling water connections in engine rooms.

- Energy transportation networks: Low-resistance, long-distance turn solutions for oil and gas pipelines.

- Municipal water supply renovation: Main pipeline network turns with connections to reduce water hammer effects.

- Industrial equipment integration: Low-turbulence turns for compressor inlet/outlet pipelines.

- Agricultural irrigation systems: Large-radius water-saving turns for high-pressure main pipelines at pump stations.

- Mining slurry transportation: High wear resistance to withstand wear in slurry pipeline turns.

- Hydrodynamics optimization: Large radius design significantly reduces flow resistance and pressure loss.

- High-pressure structure strengthening: The malleable cast iron base can meet the requirements of industrial pipeline pressure.

- Wear resistance: To be used with particulate media and rate to be tested according to the ISO 6509 wear resistance test.

- Durable corrosion resistance: Hot-dip galvanized coating gives the highest possible level of corrosion protection.

- Safety certification claim:

- Relevant specifications meet the drinking water contact rules (NSF 61).

- Resistance to extreme temperatures (-30°C to 120°C).

- Complete specification coverage: DN8-DN100 meets the needs of micro-pipelines to trunks.

- Thread Protection: Dual end cap engineering plastic screw nested protection.

- Curved Surface Buffer Design: Fixed with EPE pearl cotton to bend the curved pipe shape.

- How to process the anti-rust film: Add VCI vapor phase rust inhibitor and vacuum seal.

- Integration of traceability information: packaging QR code with certificate, curvature parameters.

- The packing material with inner container of curved reinforcement design, making transportation without moving.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.