HOT PRODUCTS TAGS

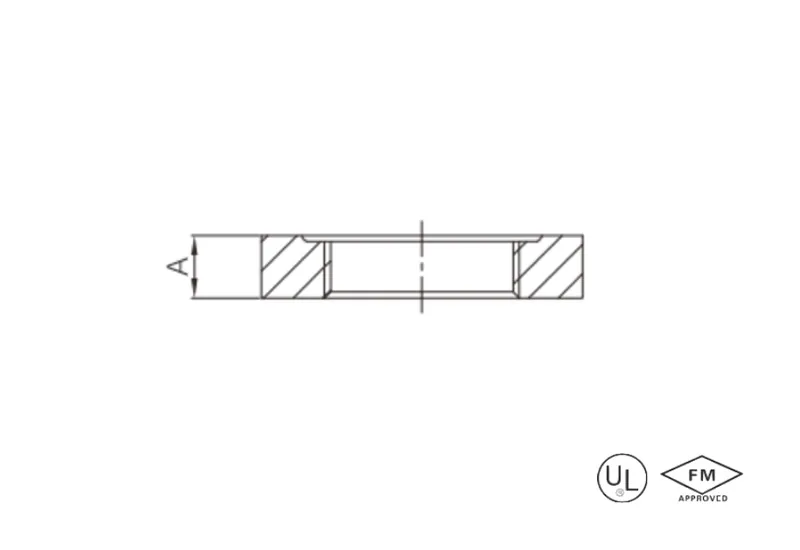

Malleable cast iron backnut (Recessed)

·Standard: ISO 49 / EN 10242

UL/FM

·Material: BS EN 1562, EN-GJMB-350-10

·Thread: BSPT

·W. pressure: 20 ~ 25 bar, ≤ PN25

·Surface: Black iron / hot dip galvanized

·Size Range: 1/2″ —4″

description

Malleable cast iron recessed backnut, concave locking prevents loosening, fits tightly, sturdy and durable.

Specification

Available size

SIZE | A(min) | ||

INCH | DN | MM | MM |

1/2″ | 15 | 21.3 | 7.9 |

3/4″ | 20 | 26.9 | 8.6 |

1″ | 25 | 33.7 | 9.7 |

1-1/4″ | 32 | 42.4 | 10.7 |

1-1/2″ | 40 | 48.3 | 11.9 |

2″ | 50 | 60.3 | 13.5 |

4″ | 100 | 114.3 | 20.3 |

application

- Fire Protection System Sealing and Reinforcement: Groove Locking Structure Ensures Long-Term Anti-Loosening of Sprinkler Pipe Network Flange Connections

- Ship Engine Room Piping: Anti-Vibration Design Solves the Risk of Fuel/Cooling Water Pipe Joint Loosening

- Industrial High-Pressure Equipment: High-Reliability Sealing and Locking Solution for Compressor/Reactor Flange Assemblies

- Maintenance of municipal valve assemblies: Quick repair solution for preventing loosening of main road valve sealing surfaces

- Energy transmission systems: Locking components for oil and gas pipeline flange connections that resist temperature difference deformation

- Agricultural irrigation hubs: Locking mechanisms for high-pressure pipelines in pump stations that prevent silt erosion

- Mining pipeline networks: Solutions for preventing loosening of flange sealing surfaces under high vibration conditions

- Chemical process equipment: Locking mechanisms for flange connections in corrosive environments that resist chemical medium erosion

advantages

- Anti-loosening structural design: Groove mechanical locking prevents thread retraction under vibration conditions.

- High-pressure sealing assurance: Compatible with BSPT tapered thread fittings to achieve 25 bar sealing conditions.

- Compact installation solution: Groove structure reduces installation space by 30% compared to traditional locking components.

- Tool Compatibility: Standard grooves compatible with standard wrenches for quick assembly and disassembly

- Wide Temperature Range Adaptability: Maintains locking force stability from -30°C to 120°C

- Full Size Range Coverage: DN15 to DN100 to meet requirements from miniature instruments to industrial main pipelines

packing

- Scratch-resistant protection: PE foam tubing wrapped around the surface of the recessed structure.

- Layered isolation design: Honeycomb cardboard dividers prevent collisions during transport.

- Anti-rust treatment: Vacuum-sealed packaging with vapor phase corrosion inhibitor (VCI) paper.

- Anti-mixing structure: Laser-cut EVA inner lining with independent slots according to specifications.

- Bulk transport solution: High-strength corrugated cardboard box unitized packaging (compliant with ISTA 2A standard).

- Traceability management: Box QR codes linked to production batches and material reports

- Anti-loss design: Inner box self-sealing bags + tamper-proof labels ensure component integrity

Available size

SIZE | A(min) | ||

INCH | DN | MM | MM |

1/2″ | 15 | 21.3 | 7.9 |

3/4″ | 20 | 26.9 | 8.6 |

1″ | 25 | 33.7 | 9.7 |

1-1/4″ | 32 | 42.4 | 10.7 |

1-1/2″ | 40 | 48.3 | 11.9 |

2″ | 50 | 60.3 | 13.5 |

4″ | 100 | 114.3 | 20.3 |

- Fire Protection System Sealing and Reinforcement: Groove Locking Structure Ensures Long-Term Anti-Loosening of Sprinkler Pipe Network Flange Connections

- Ship Engine Room Piping: Anti-Vibration Design Solves the Risk of Fuel/Cooling Water Pipe Joint Loosening

- Industrial High-Pressure Equipment: High-Reliability Sealing and Locking Solution for Compressor/Reactor Flange Assemblies

- Maintenance of municipal valve assemblies: Quick repair solution for preventing loosening of main road valve sealing surfaces

- Energy transmission systems: Locking components for oil and gas pipeline flange connections that resist temperature difference deformation

- Agricultural irrigation hubs: Locking mechanisms for high-pressure pipelines in pump stations that prevent silt erosion

- Mining pipeline networks: Solutions for preventing loosening of flange sealing surfaces under high vibration conditions

- Chemical process equipment: Locking mechanisms for flange connections in corrosive environments that resist chemical medium erosion

- Anti-loosening structural design: Groove mechanical locking prevents thread retraction under vibration conditions.

- High-pressure sealing assurance: Compatible with BSPT tapered thread fittings to achieve 25 bar sealing conditions.

- Compact installation solution: Groove structure reduces installation space by 30% compared to traditional locking components.

- Tool Compatibility: Standard grooves compatible with standard wrenches for quick assembly and disassembly

- Wide Temperature Range Adaptability: Maintains locking force stability from -30°C to 120°C

- Full Size Range Coverage: DN15 to DN100 to meet requirements from miniature instruments to industrial main pipelines

- Scratch-resistant protection: PE foam tubing wrapped around the surface of the recessed structure.

- Layered isolation design: Honeycomb cardboard dividers prevent collisions during transport.

- Anti-rust treatment: Vacuum-sealed packaging with vapor phase corrosion inhibitor (VCI) paper.

- Anti-mixing structure: Laser-cut EVA inner lining with independent slots according to specifications.

- Bulk transport solution: High-strength corrugated cardboard box unitized packaging (compliant with ISTA 2A standard).

- Traceability management: Box QR codes linked to production batches and material reports

- Anti-loss design: Inner box self-sealing bags + tamper-proof labels ensure component integrity

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.