HOT PRODUCTS TAGS

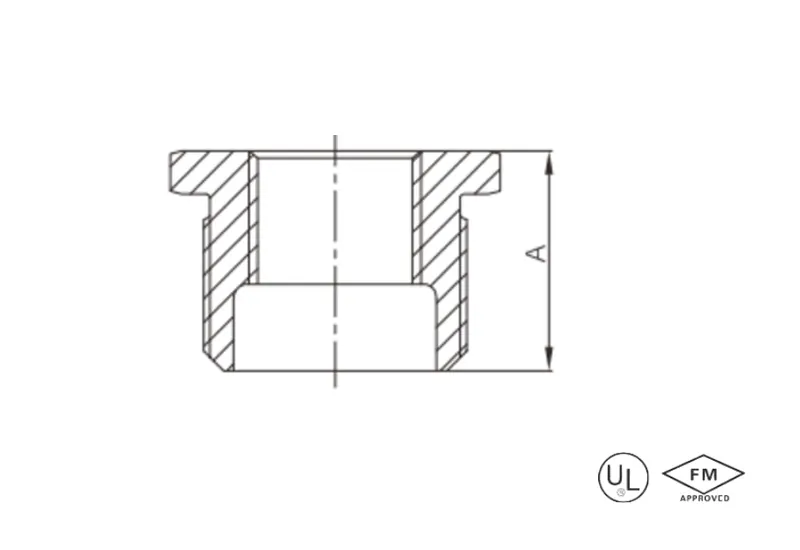

Malleable cast iron bushing

·Standard: ISO 49 / EN 10242

UL/FM

·Material: BS EN 1562, EN-GJMB-350-10

·Thread: BSPT

·W. pressure: 20 ~ 25 bar, ≤ PN25

·Surface: Black iron / hot dip galvanized

·Size Range: 1/4″ x 1/8″—4″ x 1″

description

Malleable cast iron male and female reducing socket, precise diameter-changing butt joint, sturdy, pressure-resistant, suitable for various pipe types.

Specification

Available size

| SIZE | A | ||

| INCH | DN | MM | MM |

| 1/4″ x 1/8″ | 8 x 6 | 13.5 x 10.2 | 20 |

| 3/8″ x 1/8″ | 10 x 6 | 17.2 x 10.2 | 20 |

| 3/8″ x 1/4″ | 10 x 8 | 17.2 x 13.5 | 20 |

| 1/2″ x 1/8″ | 15 x 6 | 21.3 x 10.2 | 24 |

| 1/2″ x 1/4″ | 15 x 8 | 21.3 x 13.5 | 24 |

| 1/2″ x 3/8″ | 15 x 10 | 21.3 x 17.2 | 24 |

| 3/4″ x 1/8″ | 20 x 6 | 26.9 x 10.2 | 26 |

| 3/4″ x 1/4″ | 20 x 8 | 26.9 x 13.5 | 26 |

| 3/4″ x 3/8″ | 20 x 10 | 26.9 x 17.2 | 26 |

| 3/4″ x 1/2″ | 20 x 15 | 26.9 x 21.3 | 26 |

| 1″ x 1/4″ | 25 x 8 | 33.7 x 13.5 | 29 |

| 1″ x 3/8″ | 25 x 10 | 33.7 x 17.2 | 29 |

| 1″ x 1/2″ | 25 x 15 | 33.7 x 21.3 | 29 |

| 1″ x 3/4″ | 25 x 20 | 33.7 x 26.9 | 29 |

| 1-1/4″ x 3/8″ | 32 x 10 | 42.4 x 17.2 | 31 |

| 1-1/4″ x 1/2″ | 32 x 15 | 42.4 x 21.3 | 31 |

| 1-1/4″ x 3/4″ | 32 x 20 | 42.4 x 26.9 | 31 |

| 1-1/4″ x 1″ | 32 x 25 | 42.4 x 33.7 | 31 |

| 1-1/2″ x 1/4″ | 40 x 8 | 48.3 x 13.5 | 31 |

| 1-1/2″ x 3/8″ | 40 x 10 | 48.3 x 17.2 | 31 |

| 1-1/2″ x 1/2″ | 40 x 15 | 48.3 x 21.3 | 31 |

| 1-1/2″ x 3/4″ | 40 x 20 | 48.3 x 26.9 | 31 |

| 1-1/2″ x 1″ | 40 x 25 | 48.3 x 33.7 | 31 |

| 1-1/2″ x 1-1/4″ | 40 x 32 | 48.3 x 42.4 | 31 |

| 2″ x 1/2″ | 50 x 15 | 60.3 x 21.3 | 31 |

| 2″ x 1/2″ | 50 x 15 | 60.3 x 21.3 | 31 |

| 2″ x 3/4″ | 50 x 20 | 60.3 x 26.9 | 31 |

| 2″ x 3/4″ | 50 x 20 | 60.3 x 26.9 | 31 |

| 2″ x 1″ | 50 x 25 | 60.3 x 33.7 | 31 |

| 2″ x 1-1/4″ | 50 x 32 | 60.3 x 42.4 | 35 |

| 2″ x 1-1/2″ | 50 x 40 | 60.3 x 48.3 | 35 |

| 2-1/2″ x 1/2″ | 65 x 15 | 76.1 x 21.3 | 40 |

| 2-1/2″ x 3/4″ | 65 x 20 | 76.1 x 26.9 | 40 |

| 2-1/2″ x 1″ | 65 x 25 | 76.1 x 33.7 | 40 |

| 2-1/2″ x 1-1/4″ | 65 x 32 | 76.1 x 42.4 | 40 |

| 2-1/2″ x 1-1/2″ | 65 x 40 | 76.1 x 48.3 | 40 |

| 2-1/2″ x 2″ | 65 x 50 | 76.1 x 60.3 | 40 |

| 3″ x 1/2″ | 80 x 15 | 88.9 x 21.3 | 44 |

| 3″ x 3/4″ | 80 x 20 | 88.9 x 26.9 | 44 |

| 3″ x 3/4″ | 80 x 20 | 88.9 x 26.9 | 44 |

| 3″ x 1″ | 80 x 25 | 88.9 x 33.7 | 44 |

| 3″ x 1-1/4″ | 80 x 32 | 88.9 x 42.4 | 44 |

| 3″ x 1-1/2″ | 80 x 40 | 88.9 x 48.3 | 44 |

| 3″ x 2″ | 80 x 50 | 88.9 x 60.3 | 44 |

| 3″ x 2-1/2″ | 80 x 65 | 88.9 x 76.1 | 44 |

| 4″ x 1/2″ | 100 x 15 | 114.3 x 21.3 | 51 |

| 4″ x 3/4″ | 100 x 20 | 114.3 x 26.9 | 51 |

| 4″ x 1″ | 100 x 25 | 114.3 x 33.7 | 51 |

| 4″ x 1-1/4″ | 100 x 32 | 114.3 x 42.4 | 51 |

| 4″ x 1-1/2″ | 100 x 40 | 114.3 x 48.3 | 51 |

| 4″ x 2″ | 100 x 50 | 114.3 x 60.3 | 51 |

| 4″ x 2-1/2″ | 100 x 65 | 114.3 x 76.1 | 51 |

| 4″ x 3″ | 100 x 80 | 114.3 x 88.9 | 51 |

Note: NSF 61 certificate is available for M2802 ~ M2853, except M2801, M2804, M2807, M2815, M2819, M2820.

application

- Process control instrumentation connections: Enabling precise instrumentation piping to seamlessly connect with industrial main pipelines through variable-diameter interfaces.

- Fire protection system retrofits: UL/FM certification ensures high-pressure sealed connections between sprinkler branch pipes and main pipelines.

- Marine propulsion systems: Compact solutions for micro-variable-diameter interfaces in engine room fuel/coolant piping.

- Municipal water supply systems: Leak-free variable-diameter retrofits between household branch pipes and main distribution networks.

- Industrial equipment integration: Integration of compressor micro-tube interfaces with process main pipelines.

- Agricultural irrigation systems: Precision diameter transition connections between pump station outlets and drip irrigation networks.

- Chemical sampling networks: Synchronized sampling interfaces with micro-tube diameter transitions at reaction vessel monitoring ports.

- Energy metering systems: Leak-free diameter transition connections for oil and gas pipeline instrument interfaces.

advantages

- Ultra-slim size high-pressure sealing: BSPT conical thread two-way zero leakage structure design

- Safety and compliance certification: meets the specifications set for drinking water contamination prevention

- Inverter-size flexibility: Suitable for tubing micromeasurement of hole to industrial pipeline sizeconversion

- This tapered flow channel design enables a low- turbulence size transition, which would facilitate fluid optimization scales.

- Highly durable corrosion protection: Heavy corrosion environment hot-dip galvanized coating withstanding

- Enhanced Structural Design: Thickened pipe wall with reinforced design for strong mechanical strength and strong impact resistance.

- Space Efficiency: Much less space required for installation versus traditional connection

- Thread precision, industrial-grade sealing requirements .

packing

- Two layers of protection: Special engineering plastic cover + Elastic sealing ring compositepackaging

- Buffer protection design: high-density EPE cushioning is closely attached to the curve surface of different diameters

- Rust prevention treatment: composite sealing process with volatile anti-rust film and anti-oxidation layer material

- Exact fit: Hardwood slots are laser-cut for precise positioning

- Arrow variable diagram identification: Etched flow direction and between the fluid in and out identifiers on the outer box

- Transport Packaging Heavy -duty wooden box and meet international standards of fumigation

- Tracing: a-type general goods box body coding and product certification, orthogonal parameter

- Construction is made with vibration insulation design absorb transportational vibration energy by using Elastic damping matrix

Available size

| SIZE | A | ||

| INCH | DN | MM | MM |

| 1/4″ x 1/8″ | 8 x 6 | 13.5 x 10.2 | 20 |

| 3/8″ x 1/8″ | 10 x 6 | 17.2 x 10.2 | 20 |

| 3/8″ x 1/4″ | 10 x 8 | 17.2 x 13.5 | 20 |

| 1/2″ x 1/8″ | 15 x 6 | 21.3 x 10.2 | 24 |

| 1/2″ x 1/4″ | 15 x 8 | 21.3 x 13.5 | 24 |

| 1/2″ x 3/8″ | 15 x 10 | 21.3 x 17.2 | 24 |

| 3/4″ x 1/8″ | 20 x 6 | 26.9 x 10.2 | 26 |

| 3/4″ x 1/4″ | 20 x 8 | 26.9 x 13.5 | 26 |

| 3/4″ x 3/8″ | 20 x 10 | 26.9 x 17.2 | 26 |

| 3/4″ x 1/2″ | 20 x 15 | 26.9 x 21.3 | 26 |

| 1″ x 1/4″ | 25 x 8 | 33.7 x 13.5 | 29 |

| 1″ x 3/8″ | 25 x 10 | 33.7 x 17.2 | 29 |

| 1″ x 1/2″ | 25 x 15 | 33.7 x 21.3 | 29 |

| 1″ x 3/4″ | 25 x 20 | 33.7 x 26.9 | 29 |

| 1-1/4″ x 3/8″ | 32 x 10 | 42.4 x 17.2 | 31 |

| 1-1/4″ x 1/2″ | 32 x 15 | 42.4 x 21.3 | 31 |

| 1-1/4″ x 3/4″ | 32 x 20 | 42.4 x 26.9 | 31 |

| 1-1/4″ x 1″ | 32 x 25 | 42.4 x 33.7 | 31 |

| 1-1/2″ x 1/4″ | 40 x 8 | 48.3 x 13.5 | 31 |

| 1-1/2″ x 3/8″ | 40 x 10 | 48.3 x 17.2 | 31 |

| 1-1/2″ x 1/2″ | 40 x 15 | 48.3 x 21.3 | 31 |

| 1-1/2″ x 3/4″ | 40 x 20 | 48.3 x 26.9 | 31 |

| 1-1/2″ x 1″ | 40 x 25 | 48.3 x 33.7 | 31 |

| 1-1/2″ x 1-1/4″ | 40 x 32 | 48.3 x 42.4 | 31 |

| 2″ x 1/2″ | 50 x 15 | 60.3 x 21.3 | 31 |

| 2″ x 1/2″ | 50 x 15 | 60.3 x 21.3 | 31 |

| 2″ x 3/4″ | 50 x 20 | 60.3 x 26.9 | 31 |

| 2″ x 3/4″ | 50 x 20 | 60.3 x 26.9 | 31 |

| 2″ x 1″ | 50 x 25 | 60.3 x 33.7 | 31 |

| 2″ x 1-1/4″ | 50 x 32 | 60.3 x 42.4 | 35 |

| 2″ x 1-1/2″ | 50 x 40 | 60.3 x 48.3 | 35 |

| 2-1/2″ x 1/2″ | 65 x 15 | 76.1 x 21.3 | 40 |

| 2-1/2″ x 3/4″ | 65 x 20 | 76.1 x 26.9 | 40 |

| 2-1/2″ x 1″ | 65 x 25 | 76.1 x 33.7 | 40 |

| 2-1/2″ x 1-1/4″ | 65 x 32 | 76.1 x 42.4 | 40 |

| 2-1/2″ x 1-1/2″ | 65 x 40 | 76.1 x 48.3 | 40 |

| 2-1/2″ x 2″ | 65 x 50 | 76.1 x 60.3 | 40 |

| 3″ x 1/2″ | 80 x 15 | 88.9 x 21.3 | 44 |

| 3″ x 3/4″ | 80 x 20 | 88.9 x 26.9 | 44 |

| 3″ x 3/4″ | 80 x 20 | 88.9 x 26.9 | 44 |

| 3″ x 1″ | 80 x 25 | 88.9 x 33.7 | 44 |

| 3″ x 1-1/4″ | 80 x 32 | 88.9 x 42.4 | 44 |

| 3″ x 1-1/2″ | 80 x 40 | 88.9 x 48.3 | 44 |

| 3″ x 2″ | 80 x 50 | 88.9 x 60.3 | 44 |

| 3″ x 2-1/2″ | 80 x 65 | 88.9 x 76.1 | 44 |

| 4″ x 1/2″ | 100 x 15 | 114.3 x 21.3 | 51 |

| 4″ x 3/4″ | 100 x 20 | 114.3 x 26.9 | 51 |

| 4″ x 1″ | 100 x 25 | 114.3 x 33.7 | 51 |

| 4″ x 1-1/4″ | 100 x 32 | 114.3 x 42.4 | 51 |

| 4″ x 1-1/2″ | 100 x 40 | 114.3 x 48.3 | 51 |

| 4″ x 2″ | 100 x 50 | 114.3 x 60.3 | 51 |

| 4″ x 2-1/2″ | 100 x 65 | 114.3 x 76.1 | 51 |

| 4″ x 3″ | 100 x 80 | 114.3 x 88.9 | 51 |

Note: NSF 61 certificate is available for M2802 ~ M2853, except M2801, M2804, M2807, M2815, M2819, M2820.

- Process control instrumentation connections: Enabling precise instrumentation piping to seamlessly connect with industrial main pipelines through variable-diameter interfaces.

- Fire protection system retrofits: UL/FM certification ensures high-pressure sealed connections between sprinkler branch pipes and main pipelines.

- Marine propulsion systems: Compact solutions for micro-variable-diameter interfaces in engine room fuel/coolant piping.

- Municipal water supply systems: Leak-free variable-diameter retrofits between household branch pipes and main distribution networks.

- Industrial equipment integration: Integration of compressor micro-tube interfaces with process main pipelines.

- Agricultural irrigation systems: Precision diameter transition connections between pump station outlets and drip irrigation networks.

- Chemical sampling networks: Synchronized sampling interfaces with micro-tube diameter transitions at reaction vessel monitoring ports.

- Energy metering systems: Leak-free diameter transition connections for oil and gas pipeline instrument interfaces.

- Ultra-slim size high-pressure sealing: BSPT conical thread two-way zero leakage structure design

- Safety and compliance certification: meets the specifications set for drinking water contamination prevention

- Inverter-size flexibility: Suitable for tubing micromeasurement of hole to industrial pipeline sizeconversion

- This tapered flow channel design enables a low- turbulence size transition, which would facilitate fluid optimization scales.

- Highly durable corrosion protection: Heavy corrosion environment hot-dip galvanized coating withstanding

- Enhanced Structural Design: Thickened pipe wall with reinforced design for strong mechanical strength and strong impact resistance.

- Space Efficiency: Much less space required for installation versus traditional connection

- Thread precision, industrial-grade sealing requirements .

- Two layers of protection: Special engineering plastic cover + Elastic sealing ring compositepackaging

- Buffer protection design: high-density EPE cushioning is closely attached to the curve surface of different diameters

- Rust prevention treatment: composite sealing process with volatile anti-rust film and anti-oxidation layer material

- Exact fit: Hardwood slots are laser-cut for precise positioning

- Arrow variable diagram identification: Etched flow direction and between the fluid in and out identifiers on the outer box

- Transport Packaging Heavy -duty wooden box and meet international standards of fumigation

- Tracing: a-type general goods box body coding and product certification, orthogonal parameter

- Construction is made with vibration insulation design absorb transportational vibration energy by using Elastic damping matrix

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.