HOT PRODUCTS TAGS

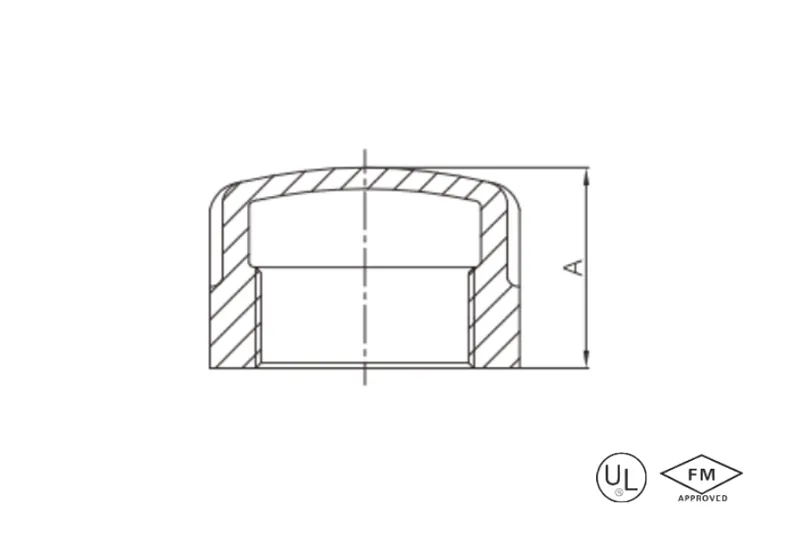

Malleable cast iron cap

·Standard: ISO 49 / EN 10242

UL/FM

·Material: BS EN 1562, EN-GJMB-350-10

·Thread: BSPT

·W. pressure: 20 ~ 25 bar, ≤ PN25

·Surface: Black iron / hot dip galvanized

·Size Range: 1/4″ —4″

description

Malleable cast iron cap, tightly seals pipe ends, rust-proof and wear-resistant, provides reliable end protection.

Specification

Available size

| SIZE | A(min) | ||

| INCH | DN | MM | MM |

| 1/4″ | 8 | 13.5 | 15 |

| 3/8″ | 10 | 17.2 | 17 |

| 1/2″ | 15 | 21.3 | 19 |

| 3/4″ | 20 | 26.9 | 22 |

| 1″ | 25 | 33.7 | 24 |

| 1-1/4″ | 32 | 42.4 | 27 |

| 1-1/2″ | 40 | 48.3 | 27 |

| 2″ | 50 | 60.3 | 32 |

| 2-1/2″ | 65 | 76.1 | 35 |

| 3″ | 80 | 88.9 | 38 |

| 4″ | 100 | 114.3 | 45 |

Note: NSF 61 certificate is available for M3401 ~ M3411.

application

- Pipeline system terminal protection: Provide reliable sealing protection for the end of the fire sprinkler network

- Ship Line Maintenance: Engine room fuel/cooling water pipeline terminal anti-corrosion sealing solutions

- Industrial equipment closure: The compressor/reactor process pipeline access port is temporarily closed

- Municipal pipe network transformation: The end of the main road branch pipeline prevents foreign objects from entering and sealing

- Energy transmission system: long-term protection solution for reserved interfaces of oil and gas pipelines

- Agricultural irrigation network: the terminal of the pumping station outlet is closed to prevent sediment erosion

- Chemical process installations: Chemical-resistant seals for corrosive media pipe terminals

- Mine piping systems: protective closure of pipeline ports in high-wear environments

advantages

- Terminal seal guarantee: The tapered thread structure realizes the permanent closure of the end of the pipe

- High pressure protection performance: meet the pressure requirements of industrial piping system terminals

- Long-lasting anti-corrosion design: Hot-dip galvanized layer provides comprehensive corrosion protection

- Structural Integrity: Malleable iron matrix ensures impact strength at the end

- Ease of installation: Standard wrench operation allows for quick installation and removal

- Full specification adaptation: covering micro meter tubes to industrial main pipe terminals.

packing

- End face protection system: Customized PE cushion pads fit tightly to seal the end face.

- Thread protection design: Engineering plastic screw cap nested protection thread.

- Anti-rust treatment: Vapor phase corrosion inhibitor vacuum sealed packaging.

- Unitized packing: High-strength corrugated box layered positioning packaging.

- Traceability management: Box QR code linked to certification information and specification parameters.

- Anti-collision design: Corner protection strips inside the box prevent damage during transportation.

Available size

| SIZE | A(min) | ||

| INCH | DN | MM | MM |

| 1/4″ | 8 | 13.5 | 15 |

| 3/8″ | 10 | 17.2 | 17 |

| 1/2″ | 15 | 21.3 | 19 |

| 3/4″ | 20 | 26.9 | 22 |

| 1″ | 25 | 33.7 | 24 |

| 1-1/4″ | 32 | 42.4 | 27 |

| 1-1/2″ | 40 | 48.3 | 27 |

| 2″ | 50 | 60.3 | 32 |

| 2-1/2″ | 65 | 76.1 | 35 |

| 3″ | 80 | 88.9 | 38 |

| 4″ | 100 | 114.3 | 45 |

Note: NSF 61 certificate is available for M3401 ~ M3411.

- Pipeline system terminal protection: Provide reliable sealing protection for the end of the fire sprinkler network

- Ship Line Maintenance: Engine room fuel/cooling water pipeline terminal anti-corrosion sealing solutions

- Industrial equipment closure: The compressor/reactor process pipeline access port is temporarily closed

- Municipal pipe network transformation: The end of the main road branch pipeline prevents foreign objects from entering and sealing

- Energy transmission system: long-term protection solution for reserved interfaces of oil and gas pipelines

- Agricultural irrigation network: the terminal of the pumping station outlet is closed to prevent sediment erosion

- Chemical process installations: Chemical-resistant seals for corrosive media pipe terminals

- Mine piping systems: protective closure of pipeline ports in high-wear environments

- Terminal seal guarantee: The tapered thread structure realizes the permanent closure of the end of the pipe

- High pressure protection performance: meet the pressure requirements of industrial piping system terminals

- Long-lasting anti-corrosion design: Hot-dip galvanized layer provides comprehensive corrosion protection

- Structural Integrity: Malleable iron matrix ensures impact strength at the end

- Ease of installation: Standard wrench operation allows for quick installation and removal

- Full specification adaptation: covering micro meter tubes to industrial main pipe terminals.

- End face protection system: Customized PE cushion pads fit tightly to seal the end face.

- Thread protection design: Engineering plastic screw cap nested protection thread.

- Anti-rust treatment: Vapor phase corrosion inhibitor vacuum sealed packaging.

- Unitized packing: High-strength corrugated box layered positioning packaging.

- Traceability management: Box QR code linked to certification information and specification parameters.

- Anti-collision design: Corner protection strips inside the box prevent damage during transportation.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.