HOT PRODUCTS TAGS

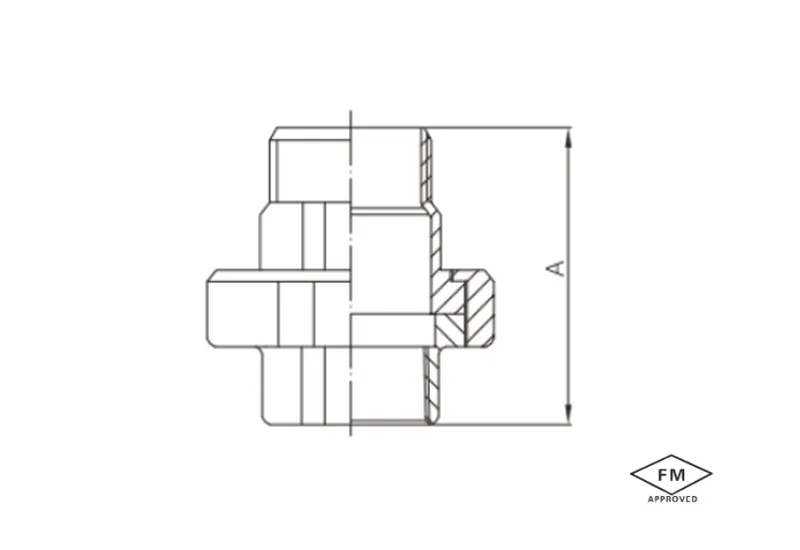

Malleable cast iron male and female union (Flat / taper seat)

·Standard: ISO 49 / EN 10242

UL/FM

·Material: BS EN 1562, EN-GJMB-350-10

·Thread: BSPT

·W. pressure: 20 ~ 25 bar, ≤ PN25

·Surface: Black iron / hot dip galvanized

·Size Range: 1/2″ —4″

description

Malleable cast iron male and female union (Flat /taper seat), flat/taper seat for tight sealing, quick socket installation, suitable for various pipelines.

Specification

Available size

SIZE | A | Type | ||

INCH | DN | MM | MM |

|

1/2″ | 15 | 21.3 | 66 | Flat seat / taper seat |

3/4″ | 20 | 26.9 | 72 | Flat seat / taper seat |

1″ | 25 | 33.7 | 80 | Flat seat / taper seat |

1-1/4″ | 32 | 42.4 | 90 | Flat seat / taper seat |

1-1/2″ | 40 | 48.3 | 95 | Flat seat / taper seat |

2″ | 50 | 60.3 | 106 | Flat seat / taper seat |

2-1/2″ | 65 | 76.1 | 118 | Flat seat / taper seat |

3″ | 80 | 88.9 | 130 | Flat seat / taper seat |

4″ | 100 | 114.3 | 133 | Flat seat / taper seat |

Note:

1.For flat seat, it must be fitted together with gasket for sealing, and TPMC could supply rubber gasket separately.

2.For taper (conical) seat, it is self-sealing without gasket.

3.For taper seat material of head and tail, it is malleable iron, and also available with both brass rings as customized.

4.NSF 61 certificate is available for M3903 ~ M3908, except M3909 ~ M3911.

application

- Building plumbing systems: Flat seat/cone seat designs accommodate pipe connections with different sealing requirements.

- HVAC engineering: Quick-connect structures simplify pipe installation processes.

- Industrial fluid conveyance: Malleable cast iron materials meet conventional pressure conditions.

- Agricultural irrigation networks: Standardized dimensions match mainstream water supply pipe specifications.

- Municipal pipe maintenance: Cone seat self-sealing characteristics are suitable for temporary emergency repairs.

advantages

- Double sealing solution: GASKETS are required for flat seats; CONE SEATS provide Self-Sealing without a need for gaskets.

- Flexibility: The standard material is malleable cast iron with the possibility to place brass rings at both ends for further customization.

- Installation is made quicker: The plug-in structure provides a much faster pipeline assembly.

- Certified Drinking Water Safety (NSF 61), model: M3903~M3908

- Wide size coverage: Ranges from 1/2 inch to 4 inches fit various pipeline connection applications.

packing

- Separate protection: Flat seat/cone seat joints are packaged in separate scratch-proof bags.

- Size identification: Three sets of specifications (inches/DN/millimeters) are clearly marked on the outer box.

- Sealing component accessories: Flat seat joints come standard with separately packaged rubber gaskets.

- Certification marking: Products that have passed NSF certification have a special mark printed on the outer box.

- Stacking optimization: The hexagonal packaging structure improves transportation space utilization.

Available size

SIZE | A | Type | ||

INCH | DN | MM | MM |

|

1/2″ | 15 | 21.3 | 66 | Flat seat / taper seat |

3/4″ | 20 | 26.9 | 72 | Flat seat / taper seat |

1″ | 25 | 33.7 | 80 | Flat seat / taper seat |

1-1/4″ | 32 | 42.4 | 90 | Flat seat / taper seat |

1-1/2″ | 40 | 48.3 | 95 | Flat seat / taper seat |

2″ | 50 | 60.3 | 106 | Flat seat / taper seat |

2-1/2″ | 65 | 76.1 | 118 | Flat seat / taper seat |

3″ | 80 | 88.9 | 130 | Flat seat / taper seat |

4″ | 100 | 114.3 | 133 | Flat seat / taper seat |

Note:

1.For flat seat, it must be fitted together with gasket for sealing, and TPMC could supply rubber gasket separately.

2.For taper (conical) seat, it is self-sealing without gasket.

3.For taper seat material of head and tail, it is malleable iron, and also available with both brass rings as customized.

4.NSF 61 certificate is available for M3903 ~ M3908, except M3909 ~ M3911.

- Building plumbing systems: Flat seat/cone seat designs accommodate pipe connections with different sealing requirements.

- HVAC engineering: Quick-connect structures simplify pipe installation processes.

- Industrial fluid conveyance: Malleable cast iron materials meet conventional pressure conditions.

- Agricultural irrigation networks: Standardized dimensions match mainstream water supply pipe specifications.

- Municipal pipe maintenance: Cone seat self-sealing characteristics are suitable for temporary emergency repairs.

- Double sealing solution: GASKETS are required for flat seats; CONE SEATS provide Self-Sealing without a need for gaskets.

- Flexibility: The standard material is malleable cast iron with the possibility to place brass rings at both ends for further customization.

- Installation is made quicker: The plug-in structure provides a much faster pipeline assembly.

- Certified Drinking Water Safety (NSF 61), model: M3903~M3908

- Wide size coverage: Ranges from 1/2 inch to 4 inches fit various pipeline connection applications.

- Separate protection: Flat seat/cone seat joints are packaged in separate scratch-proof bags.

- Size identification: Three sets of specifications (inches/DN/millimeters) are clearly marked on the outer box.

- Sealing component accessories: Flat seat joints come standard with separately packaged rubber gaskets.

- Certification marking: Products that have passed NSF certification have a special mark printed on the outer box.

- Stacking optimization: The hexagonal packaging structure improves transportation space utilization.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.