HOT PRODUCTS TAGS

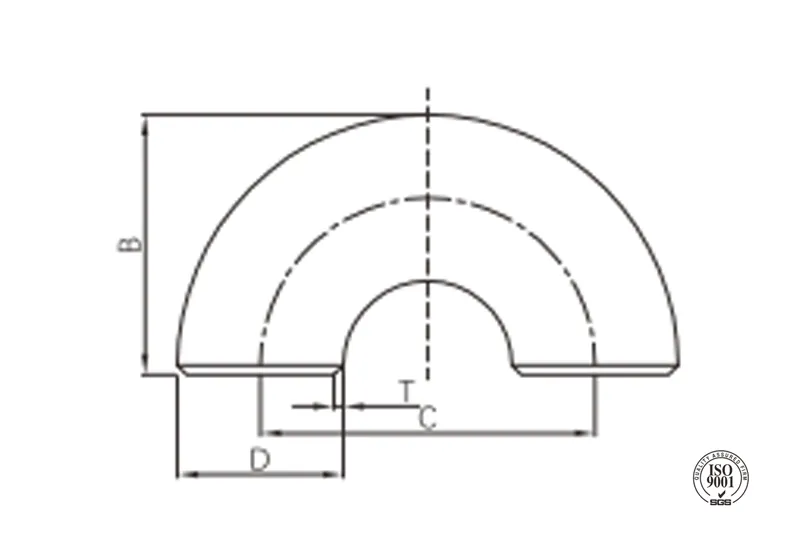

Butt weld 180° return bend (Short radius)

·Standard: ISO

EN 10253-1 / EN 10253-2 / EN 10253-3

·Material: Carbon steel S235 / P235TR2

SS equivalent to WP304 / WP316L

·Type: Short radius, 2D, R=1.0D

·W. pressure: Equal to same straight pipe

·Surface: Black painting / hot dip galvanized

Pickling white, etc.

·Size range: 1″-24″

description

butt weld 180 ° return bend (long radius), significantly reducing fluid resistance and energy loss, combined with butt welding connection to ensure high sealing and structural strength.

Specification

Available size

| Size | Preferred T to EN 10253-2(mm) | C(mm) | B(mm) | ||

| NPS | DN | OD(mm) | |||

| 1/2″ | 15 | 21.3 | 2.0/2.6/3.2/4.0/5.0/7.1 | 50 | 36 |

| 3/4″ | 20 | 26.9 | 2.3/2.6/3.214.014.5/5.6/8.0 | 50 | 39 |

| 1″ | 25 | 33.7 | 2.6/3.2/4.014.5/5.6/6.3/8.8 | 50 | 42 |

| 1-1/4″ | 32 | 42.4 | 2.6/3.6/4.0/5.0/6.3/8.0/10.0 | 64 | 53 |

| 1-1/2″ | 40 | 48.3 | 2.6/3.614.0/5.0/6.3/8.0/10.0 | 76 | 62 |

| 2″ | 50 | 60.3 | 2.9/3.614.0/5.6/7.1/8.8/11.0 | 102 | 81 |

| 2-1/2″ | 65 | 76.1 | 2.9/3.6/5.617.1/8.0/10.0/14.2 | 127 | 102 |

| 3″ | 80 | 88.9 | 3.2/4.0/5.6/8.0/8.8/11.0/16.0 | 152 | 121 |

| 4″ | 100 | 114.3 | 3.6/4.5/6.3/8.8/11.0/14.2/17.5 | 203 | 159 |

| 5″ | 125 | 139.7 | 4.0/5.0/6.3/10.0/12.5/16.0/20.0 | 254 | 197 |

| 6″ | 150 | 165.1/168.3 | 4.014.5/5.6/7.1/11.0/14.2/17.5/22.2 | 305 | 237 |

| 8″ | 200 | 219.1 | 4.5/6.317.1/8.0/12.5/16.0/17.5/22.2 | 406 | 313 |

| 10″ | 250 | 273.0 | 5.0/6.3/8.8/10.0/12.5/16.0/22.2/30.0 | 508 | 391 |

| 12″ | 300 | 323.9 | 5.6/7.1/8.8/10.0/12.5/17.5/25.0/32.0 | 610 | 467 |

| 14″ | 350 | 355.6 | 5.6/8.0/10.0/12.5/16.0/20.0/28.0/36.0 | 711 | 533 |

| 16″ | 400 | 406.4 | 6.3/8.8/10.0/12.5/17.5/22.2/30.0/40.0 | 813 | 610 |

| 18″ | 450 | 457 | 6.3/10.0/11.0/12.5117.5/22.2/32.0/45.0 | 914 | 686 |

| 20″ | 500 | 508 | 6.3/10.0/11.0/12.5117.5/25.0/36.0/50.0 | 1016 | 762 |

| 24″ | 600 | 610 | 6.3/10.0/12.5/17.5/25.0/30.0145.0/60.0 | 1220 | 914 |

application

- Specially designed for 180° pipe turns in extremely confined spaces, suitable for compact equipment layouts (such as internal piping of units and equipment interlayers).

- Used in situations requiring rapid backflow and with limited installation space, such as ship engine rooms, mobile pressure vessels, and modular chemical plants.

- Replaces long-radius elbow or multiple elbow combinations to minimize installation volume.

advantages

- Maximum space utilization: the quick turn round Ø 1.0D breaks through spatial limitations with an industry-best turning radius of 180°.

- The design based on full welded construction ensures zero-leakage, no-joint, making it equivalent to straight pipe in pressure bearing capacity.

- Expanded material compatibility: Carbon steel (S235/P235TR2) or stainless steel (WP304/WP316L equivalent), ideal for corrosive or clean environments.

- Increased installation efficiency: one-component replacement of multiple parts. more than 50% off the welding points, construction schedule reduction and labour costs saving.

- Surface reinforcement method: black paint protection, hot-dip galvanizing or acid washing passivation, improve weather resistance and service life.

packing

- Anti-deformation reinforced packaging:Customized wooden boxes + internal support frames are used to prevent U-shaped structures from deforming during transportation.

- Double port protection:High-strength engineering plastic plugs are installed on the pipe ports, covered with cushioning foam sleeves.

- Anti-rust core technology:The surface is covered with vapor phase corrosion inhibitor (VCI) film, suitable for the humid environment of sea transportation.

- Intelligent Identification System:Outer boxes are labeled with product name, angle type (short radius), dimensions, and a “Fragile Component” warning label.

Available size

| Size | Preferred T to EN 10253-2(mm) | C(mm) | B(mm) | ||

| NPS | DN | OD(mm) | |||

| 1/2″ | 15 | 21.3 | 2.0/2.6/3.2/4.0/5.0/7.1 | 50 | 36 |

| 3/4″ | 20 | 26.9 | 2.3/2.6/3.214.014.5/5.6/8.0 | 50 | 39 |

| 1″ | 25 | 33.7 | 2.6/3.2/4.014.5/5.6/6.3/8.8 | 50 | 42 |

| 1-1/4″ | 32 | 42.4 | 2.6/3.6/4.0/5.0/6.3/8.0/10.0 | 64 | 53 |

| 1-1/2″ | 40 | 48.3 | 2.6/3.614.0/5.0/6.3/8.0/10.0 | 76 | 62 |

| 2″ | 50 | 60.3 | 2.9/3.614.0/5.6/7.1/8.8/11.0 | 102 | 81 |

| 2-1/2″ | 65 | 76.1 | 2.9/3.6/5.617.1/8.0/10.0/14.2 | 127 | 102 |

| 3″ | 80 | 88.9 | 3.2/4.0/5.6/8.0/8.8/11.0/16.0 | 152 | 121 |

| 4″ | 100 | 114.3 | 3.6/4.5/6.3/8.8/11.0/14.2/17.5 | 203 | 159 |

| 5″ | 125 | 139.7 | 4.0/5.0/6.3/10.0/12.5/16.0/20.0 | 254 | 197 |

| 6″ | 150 | 165.1/168.3 | 4.014.5/5.6/7.1/11.0/14.2/17.5/22.2 | 305 | 237 |

| 8″ | 200 | 219.1 | 4.5/6.317.1/8.0/12.5/16.0/17.5/22.2 | 406 | 313 |

| 10″ | 250 | 273.0 | 5.0/6.3/8.8/10.0/12.5/16.0/22.2/30.0 | 508 | 391 |

| 12″ | 300 | 323.9 | 5.6/7.1/8.8/10.0/12.5/17.5/25.0/32.0 | 610 | 467 |

| 14″ | 350 | 355.6 | 5.6/8.0/10.0/12.5/16.0/20.0/28.0/36.0 | 711 | 533 |

| 16″ | 400 | 406.4 | 6.3/8.8/10.0/12.5/17.5/22.2/30.0/40.0 | 813 | 610 |

| 18″ | 450 | 457 | 6.3/10.0/11.0/12.5117.5/22.2/32.0/45.0 | 914 | 686 |

| 20″ | 500 | 508 | 6.3/10.0/11.0/12.5117.5/25.0/36.0/50.0 | 1016 | 762 |

| 24″ | 600 | 610 | 6.3/10.0/12.5/17.5/25.0/30.0145.0/60.0 | 1220 | 914 |

- Specially designed for 180° pipe turns in extremely confined spaces, suitable for compact equipment layouts (such as internal piping of units and equipment interlayers).

- Used in situations requiring rapid backflow and with limited installation space, such as ship engine rooms, mobile pressure vessels, and modular chemical plants.

- Replaces long-radius elbow or multiple elbow combinations to minimize installation volume.

- Maximum space utilization: the quick turn round Ø 1.0D breaks through spatial limitations with an industry-best turning radius of 180°.

- The design based on full welded construction ensures zero-leakage, no-joint, making it equivalent to straight pipe in pressure bearing capacity.

- Expanded material compatibility: Carbon steel (S235/P235TR2) or stainless steel (WP304/WP316L equivalent), ideal for corrosive or clean environments.

- Increased installation efficiency: one-component replacement of multiple parts. more than 50% off the welding points, construction schedule reduction and labour costs saving.

- Surface reinforcement method: black paint protection, hot-dip galvanizing or acid washing passivation, improve weather resistance and service life.

- Anti-deformation reinforced packaging:Customized wooden boxes + internal support frames are used to prevent U-shaped structures from deforming during transportation.

- Double port protection:High-strength engineering plastic plugs are installed on the pipe ports, covered with cushioning foam sleeves.

- Anti-rust core technology:The surface is covered with vapor phase corrosion inhibitor (VCI) film, suitable for the humid environment of sea transportation.

- Intelligent Identification System:Outer boxes are labeled with product name, angle type (short radius), dimensions, and a “Fragile Component” warning label.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.