HOT PRODUCTS TAGS

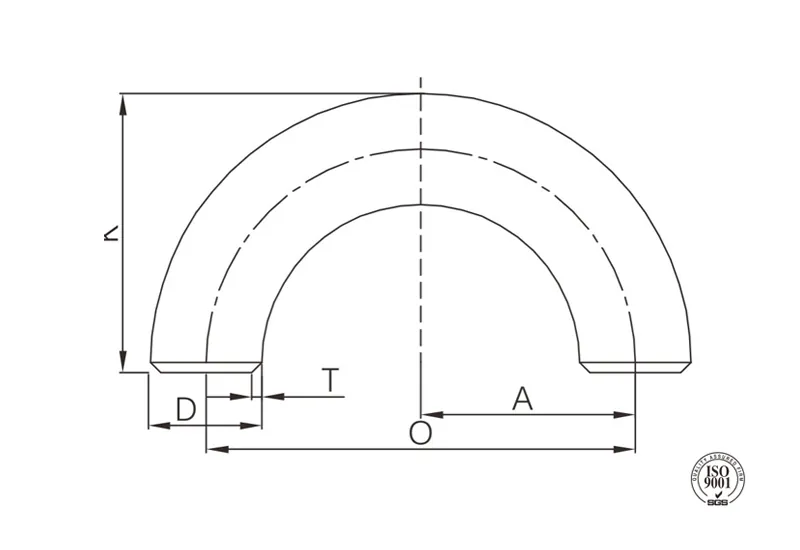

Butt weld 180° return (Long radius)

·Standard: ISO

ASME B16.9

·Material: Carbon steel ASTM A234, WPB

SS ASTM A403, WP304 / WP316L

·Type: Long radius, R=1.5D

·W. pressure: Equal to same seamless pipe

·Surface: Black painting / hot dip galvanized Pickling white, etc.

·Size range: 1″-24″

description

butt welding 180 ° return (long radius) is used to connect two pipes by butt welding, so that the pipe changes 180 degrees to change the direction of fluid flow, significantly reducing flow resistance and achieving high sealing.

Specification

Available size

| Size | Thickness (mm) | O(mm) | K(mm) | ||||

| NPS | DN | OD(mm) | Sch10 | Sch40 | Sch80 | ||

| 1/2″ | 15 | 21.3 | 2.11 | 2.77 | 3.73 | 76 | 48 |

| 3/4″ | 20 | 26.7 | 2.11 | 2.87 | 3.91 | 76 | 51 |

| 1″ | 25 | 33.4 | 2.77 | 3.38 | 4.55 | 76 | 56 |

| 1-1/4″ | 32 | 42.2 | 2.77 | 3.56 | 4.85 | 95 | 70 |

| 1-1/2″ | 40 | 48.3 | 2.77 | 3.68 | 5.08 | 114 | 83 |

| 2″ | 50 | 60.3 | 2.77 | 3.91 | 5.54 | 152 | 106 |

| 2-1/2″ | 65 | 73.0 | 3.05 | 5.16 | 7.01 | 190 | 132 |

| 3″ | 80 | 88.9 | 3.05 | 5.49 | 7.62 | 229 | 159 |

| 4″ | 100 | 114.3 | 3.05 | 6.02 | 8.56 | 305 | 210 |

| 5″ | 125 | 141.3 | 3.40 | 6.55 | 9.53 | 381 | 262 |

| 6″ | 150 | 168.3 | 3.40 | 7.11 | 10.97 | 457 | 313 |

| 8″ | 200 | 219.1 | 3.76 | 8.18 | 12.70 | 610 | 414 |

| 10″ | 250 | 273.0 | 4.19 | 9.27 | 15.09 | 762 | 518 |

| 12″ | 300 | 323.8 | 4.57 | 10.31 | 17.48 | 914 | 619 |

| 14″ | 350 | 355.6 | 6.35 | 11.13 | 19.05 | 1067 | 711 |

| 16″ | 400 | 406.4 | 6.35 | 12.70 | 21.44 | 1219 | 813 |

| 18″ | 450 | 457 | 6.35 | 14.27 | 23.83 | 1372 | 914 |

| 20″ | 500 | 508 | 6.35 | 15.09 | 26.19 | 1524 | 1016 |

| 24″ | 600 | 610 | 6.35 | 17.48 | 30.96 | 1829 | 1219 |

Note: The thickness is available with Sch5, Sch10, Sch30, Sch40, Sch80, Sch120, Sch160, STD, XS, XXS, 5S, 10S, 40S, 80S, etc.

application

- Compact flow reversal: Specifically designed for pipeline systems requiring a 180-degree turnaround, such as boiler room steam circuits, heat exchanger inlets and outlets, and chemical reaction equipment, saving installation space.

- Low-energy fluid circulation: Suitable for circulating water systems, thermal networks, and other applications requiring medium return, reducing pressure loss and improving thermal energy utilization.

- Rugged for Harsh Environments: Available in carbon steel or stainless steel versions, suitable for high-temperature, high-pressure environments in power plants and chemical plants, or clean pipelines in food and pharmaceutical industries.

- Full Size Range: Supports pipes from ½ inch to 24 inches (DN15-DN600), compatible with small equipment to industrial main pipelines.

advantages

- The savings of up to 50%: integrated U-shaped design replaces two 90-degree elbows, fewer welding tasks and the best possible pipe routings.

- No-loss fluid recirculation: Large-radius bends (1.5 x the diameter of the pipe) gently return the medium to prevent damaging bumps at pumps and valves.

- Long-term anti-corrosion: High-quality substrate passivated to resist chemical corrosion and rust, ground life of up to 20 years.

- 100% Seal Safe: Fully welded butt welding connection with the pipe, no risk of leakage from hazardous media.

- Maintenance-free design:Once the joints are welded, there are no moving parts to cause loosening and therefore no maintenance required.

- Resistant to harsh conditions: pressure and temperature resistant at pipeline level; able to receive high-temperature and -pressure fluids as steam or hot oil.

packing

- Customized protective packaging for curved surfaces:

- Each anti-rust film is fully wrapped + U-shaped foam corner protectors, placed in a thickened cardboard box (note: 180° elbow, 8 inches).

- Stainless steel products include an additional scratch-resistant pearl cotton layer.

- Large-size reinforcement solution:

- 6 inches and above use U-shaped wooden brackets, with custom foam sleeves securing the double curved surfaces of the elbows to prevent deformation during transportation.

- Efficient maritime loading:

- Small-size items are packed in nested sets, while large-size items are stacked on individual pallets, increasing container space utilization by 40%.

Available size

| Size | Thickness (mm) | O(mm) | K(mm) | ||||

| NPS | DN | OD(mm) | Sch10 | Sch40 | Sch80 | ||

| 1/2″ | 15 | 21.3 | 2.11 | 2.77 | 3.73 | 76 | 48 |

| 3/4″ | 20 | 26.7 | 2.11 | 2.87 | 3.91 | 76 | 51 |

| 1″ | 25 | 33.4 | 2.77 | 3.38 | 4.55 | 76 | 56 |

| 1-1/4″ | 32 | 42.2 | 2.77 | 3.56 | 4.85 | 95 | 70 |

| 1-1/2″ | 40 | 48.3 | 2.77 | 3.68 | 5.08 | 114 | 83 |

| 2″ | 50 | 60.3 | 2.77 | 3.91 | 5.54 | 152 | 106 |

| 2-1/2″ | 65 | 73.0 | 3.05 | 5.16 | 7.01 | 190 | 132 |

| 3″ | 80 | 88.9 | 3.05 | 5.49 | 7.62 | 229 | 159 |

| 4″ | 100 | 114.3 | 3.05 | 6.02 | 8.56 | 305 | 210 |

| 5″ | 125 | 141.3 | 3.40 | 6.55 | 9.53 | 381 | 262 |

| 6″ | 150 | 168.3 | 3.40 | 7.11 | 10.97 | 457 | 313 |

| 8″ | 200 | 219.1 | 3.76 | 8.18 | 12.70 | 610 | 414 |

| 10″ | 250 | 273.0 | 4.19 | 9.27 | 15.09 | 762 | 518 |

| 12″ | 300 | 323.8 | 4.57 | 10.31 | 17.48 | 914 | 619 |

| 14″ | 350 | 355.6 | 6.35 | 11.13 | 19.05 | 1067 | 711 |

| 16″ | 400 | 406.4 | 6.35 | 12.70 | 21.44 | 1219 | 813 |

| 18″ | 450 | 457 | 6.35 | 14.27 | 23.83 | 1372 | 914 |

| 20″ | 500 | 508 | 6.35 | 15.09 | 26.19 | 1524 | 1016 |

| 24″ | 600 | 610 | 6.35 | 17.48 | 30.96 | 1829 | 1219 |

Note: The thickness is available with Sch5, Sch10, Sch30, Sch40, Sch80, Sch120, Sch160, STD, XS, XXS, 5S, 10S, 40S, 80S, etc.

- Compact flow reversal: Specifically designed for pipeline systems requiring a 180-degree turnaround, such as boiler room steam circuits, heat exchanger inlets and outlets, and chemical reaction equipment, saving installation space.

- Low-energy fluid circulation: Suitable for circulating water systems, thermal networks, and other applications requiring medium return, reducing pressure loss and improving thermal energy utilization.

- Rugged for Harsh Environments: Available in carbon steel or stainless steel versions, suitable for high-temperature, high-pressure environments in power plants and chemical plants, or clean pipelines in food and pharmaceutical industries.

- Full Size Range: Supports pipes from ½ inch to 24 inches (DN15-DN600), compatible with small equipment to industrial main pipelines.

- The savings of up to 50%: integrated U-shaped design replaces two 90-degree elbows, fewer welding tasks and the best possible pipe routings.

- No-loss fluid recirculation: Large-radius bends (1.5 x the diameter of the pipe) gently return the medium to prevent damaging bumps at pumps and valves.

- Long-term anti-corrosion: High-quality substrate passivated to resist chemical corrosion and rust, ground life of up to 20 years.

- 100% Seal Safe: Fully welded butt welding connection with the pipe, no risk of leakage from hazardous media.

- Maintenance-free design:Once the joints are welded, there are no moving parts to cause loosening and therefore no maintenance required.

- Resistant to harsh conditions: pressure and temperature resistant at pipeline level; able to receive high-temperature and -pressure fluids as steam or hot oil.

- Customized protective packaging for curved surfaces:

- Each anti-rust film is fully wrapped + U-shaped foam corner protectors, placed in a thickened cardboard box (note: 180° elbow, 8 inches).

- Stainless steel products include an additional scratch-resistant pearl cotton layer.

- Large-size reinforcement solution:

- 6 inches and above use U-shaped wooden brackets, with custom foam sleeves securing the double curved surfaces of the elbows to prevent deformation during transportation.

- Efficient maritime loading:

- Small-size items are packed in nested sets, while large-size items are stacked on individual pallets, increasing container space utilization by 40%.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.