HOT PRODUCTS TAGS

Butt weld 180° return (Short radius)

·Standard: ISO

ASME B16.9

·Material: Carbon steel ASTM A234, WPB

SS ASTM A403, WP304 / WP316L

·Type: Short radius, R=1.0D

·W. pressure: Equal to same seamless pipe

·Surface: Black painting / hot dip galvanized Pickling white, etc.

·Size range: 1″-24″

description

butt welding 180 ° return connection (short radius) is used to connect two pipes by butt welding, so that the pipe changes 180 degrees to change the direction of fluid flow, solving the pipe return demand in space-constrained scenarios.

Specification

Available size

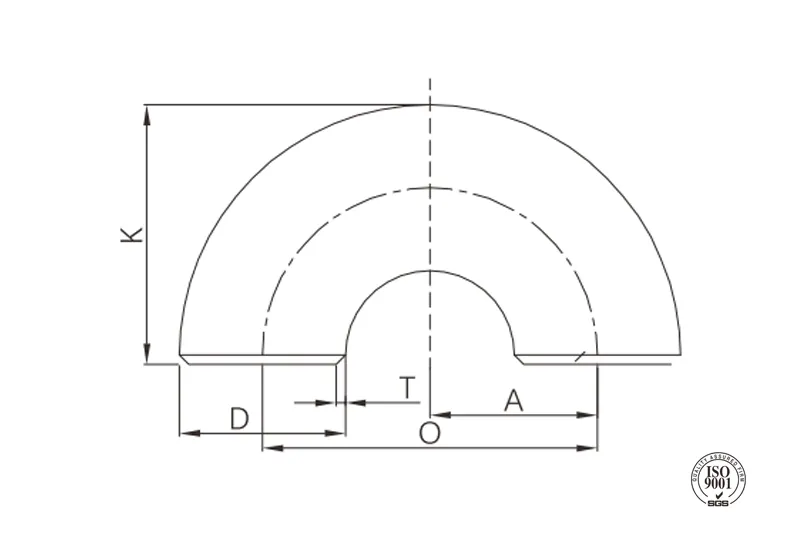

| Size | Thickness(mm) | O(mm) | K(mm) | ||||

| NPS | DN | OD(mm) | Sch10 | Sch40 | Sch80 | ||

| 1″ | 25 | 33.4 | 2.77 | 3.38 | 4.55 | 51 | 41 |

| 1-1/4″ | 32 | 42.2 | 2.77 | 3.56 | 4.85 | 64 | 52 |

| 1-1/2″ | 40 | 48.3 | 2.77 | 3.68 | 5.08 | 76 | 62 |

| 2″ | 50 | 60.3 | 2.77 | 3.91 | 5.54 | 102 | 81 |

| 2-1/2″ | 65 | 73.0 | 3.05 | 5.16 | 7.01 | 127 | 100 |

| 3″ | 80 | 88.9 | 3.05 | 5.49 | 7.62 | 152 | 121 |

| 4″ | 100 | 114.3 | 3.05 | 6.02 | 8.56 | 203 | 159 |

| 5″ | 125 | 141.3 | 3.40 | 6.55 | 9.53 | 254 | 197 |

| 6″ | 150 | 168.3 | 3.40 | 7.11 | 10.97 | 305 | 237 |

| 8″ | 200 | 219.1 | 3.76 | 8.18 | 12.70 | 406 | 313 |

| 10″ | 250 | 273.0 | 4.19 | 9.27 | 15.09 | 508 | 391 |

| 12″ | 300 | 323.8 | 4.57 | 10.31 | 17.48 | 610 | 467 |

| 14″ | 350 | 355.6 | 6.35 | 11.13 | 19.05 | 711 | 533 |

| 16″ | 400 | 406.4 | 6.35 | 12.70 | 21.44 | 813 | 610 |

| 18″ | 450 | 457 | 6.35 | 14.27 | 23.83 | 914 | 686 |

| 20″ | 500 | 508 | 6.35 | 15.09 | 26.19 | 1016 | 762 |

| 24″ | 600 | 610 | 6.35 | 17.48 | 30.96 | 1219 | 914 |

Note: The thickness is available with Sch5, Sch10, Sch30, Sch40, Sch80, Sch120, Sch160, STD, XS, XXS, 5S, 10S, 40S, 80S, etc.

application

- Extreme Space Return Flow: Specifically designed for pipe systems with limited installation space, such as ship engine rooms, compact equipment rooms, and underground pipe galleries, enabling 180-degree sharp turns for return flow.

- Low-Cost Compact Piping: Suitable for short-distance medium return scenarios (such as equipment interface return flow and small-scale circulation systems), reducing pipe usage and weld points.

- Versatile for Harsh Environments: Available in carbon steel/stainless steel versions, suitable for high-temperature, high-pressure environments in chemical plants and thermal power stations, or clean pipelines in food and pharmaceutical industries.

- Full-Size Flexible Selection: Covers pipes from 1 inch to 24 inches (DN25-DN600), meeting requirements from precision equipment to industrial main pipelines.

advantages

- Short installation distance: With short bending radius U-shaped design (1 times of pipe diameter), it can reduce even 60% space area in installation, and break through the limitation of piping arrangement in narrow regions.

- Dual-function bend:which combines component features from two 90° elbows with a straight pipe section in one part to save space and help lower the risk of leakage compared with traditional fittings.

- Lasting corrosion-proof: due to the top class base material and coated with anti-corrosion (galvalume/ aluminized steel), which could prevent chemical corrosion it appropriate for use up to 20 years under humid conditions.

- Non-stop leak protection: Butt-weld connections are fused to the pipe and do not allow hazardous media to penetrate from the hole.

- Designed with zero maintenance: after welding, there is no moving parts that make it permanently maintenance-free and help to save time and cost. Resistance to extreme conditions: Equivalent to pipes in pressure and temperature resistance, resulting in a good fit for harsh fluids like steam and hot oil .

packing

- U-shaped curved surface reinforcement protection:

- Each piece is fully wrapped in anti-rust film + custom foam corner protectors, placed in a thickened cardboard box (marked: 180° short elbow, 6 inches).

- Stainless steel products are equipped with an anti-scratch pearl cotton layer.

- Large-size deformation prevention solution:

- For 4 inches and above, a split wooden support frame is used, with U-shaped double curved surfaces secured by foam nesting, completely eliminating transportation deformation.

- Smart Loading and Transportation:

- Small-sized items are packed in nested sets, while large-sized items are stacked on individual pallets, achieving a container space utilization rate of 90%.

Available size

| Size | Thickness(mm) | O(mm) | K(mm) | ||||

| NPS | DN | OD(mm) | Sch10 | Sch40 | Sch80 | ||

| 1″ | 25 | 33.4 | 2.77 | 3.38 | 4.55 | 51 | 41 |

| 1-1/4″ | 32 | 42.2 | 2.77 | 3.56 | 4.85 | 64 | 52 |

| 1-1/2″ | 40 | 48.3 | 2.77 | 3.68 | 5.08 | 76 | 62 |

| 2″ | 50 | 60.3 | 2.77 | 3.91 | 5.54 | 102 | 81 |

| 2-1/2″ | 65 | 73.0 | 3.05 | 5.16 | 7.01 | 127 | 100 |

| 3″ | 80 | 88.9 | 3.05 | 5.49 | 7.62 | 152 | 121 |

| 4″ | 100 | 114.3 | 3.05 | 6.02 | 8.56 | 203 | 159 |

| 5″ | 125 | 141.3 | 3.40 | 6.55 | 9.53 | 254 | 197 |

| 6″ | 150 | 168.3 | 3.40 | 7.11 | 10.97 | 305 | 237 |

| 8″ | 200 | 219.1 | 3.76 | 8.18 | 12.70 | 406 | 313 |

| 10″ | 250 | 273.0 | 4.19 | 9.27 | 15.09 | 508 | 391 |

| 12″ | 300 | 323.8 | 4.57 | 10.31 | 17.48 | 610 | 467 |

| 14″ | 350 | 355.6 | 6.35 | 11.13 | 19.05 | 711 | 533 |

| 16″ | 400 | 406.4 | 6.35 | 12.70 | 21.44 | 813 | 610 |

| 18″ | 450 | 457 | 6.35 | 14.27 | 23.83 | 914 | 686 |

| 20″ | 500 | 508 | 6.35 | 15.09 | 26.19 | 1016 | 762 |

| 24″ | 600 | 610 | 6.35 | 17.48 | 30.96 | 1219 | 914 |

Note: The thickness is available with Sch5, Sch10, Sch30, Sch40, Sch80, Sch120, Sch160, STD, XS, XXS, 5S, 10S, 40S, 80S, etc.

- Extreme Space Return Flow: Specifically designed for pipe systems with limited installation space, such as ship engine rooms, compact equipment rooms, and underground pipe galleries, enabling 180-degree sharp turns for return flow.

- Low-Cost Compact Piping: Suitable for short-distance medium return scenarios (such as equipment interface return flow and small-scale circulation systems), reducing pipe usage and weld points.

- Versatile for Harsh Environments: Available in carbon steel/stainless steel versions, suitable for high-temperature, high-pressure environments in chemical plants and thermal power stations, or clean pipelines in food and pharmaceutical industries.

- Full-Size Flexible Selection: Covers pipes from 1 inch to 24 inches (DN25-DN600), meeting requirements from precision equipment to industrial main pipelines.

- Short installation distance: With short bending radius U-shaped design (1 times of pipe diameter), it can reduce even 60% space area in installation, and break through the limitation of piping arrangement in narrow regions.

- Dual-function bend:which combines component features from two 90° elbows with a straight pipe section in one part to save space and help lower the risk of leakage compared with traditional fittings.

- Lasting corrosion-proof: due to the top class base material and coated with anti-corrosion (galvalume/ aluminized steel), which could prevent chemical corrosion it appropriate for use up to 20 years under humid conditions.

- Non-stop leak protection: Butt-weld connections are fused to the pipe and do not allow hazardous media to penetrate from the hole.

- Designed with zero maintenance: after welding, there is no moving parts that make it permanently maintenance-free and help to save time and cost. Resistance to extreme conditions: Equivalent to pipes in pressure and temperature resistance, resulting in a good fit for harsh fluids like steam and hot oil .

- U-shaped curved surface reinforcement protection:

- Each piece is fully wrapped in anti-rust film + custom foam corner protectors, placed in a thickened cardboard box (marked: 180° short elbow, 6 inches).

- Stainless steel products are equipped with an anti-scratch pearl cotton layer.

- Large-size deformation prevention solution:

- For 4 inches and above, a split wooden support frame is used, with U-shaped double curved surfaces secured by foam nesting, completely eliminating transportation deformation.

- Smart Loading and Transportation:

- Small-sized items are packed in nested sets, while large-sized items are stacked on individual pallets, achieving a container space utilization rate of 90%.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.