HOT PRODUCTS TAGS

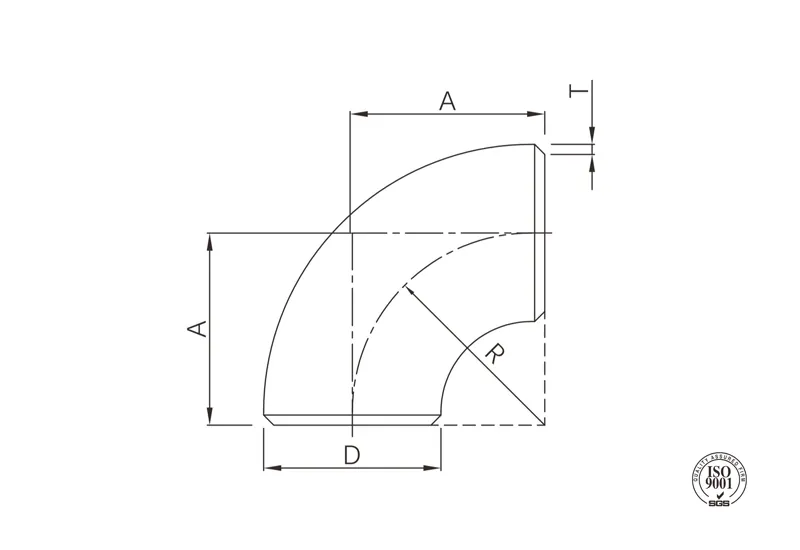

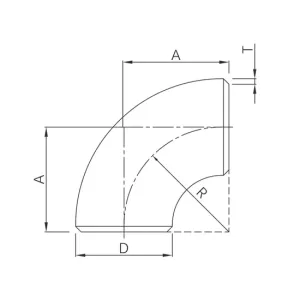

Butt weld 90° elbow (Long radius)

·Standard: ISO

ASME B16.9

·Material: Carbon steel ASTM A234, WPB

SS ASTM A403, WP304 / WP316L

·Type: Long radius, R=1.5D

·W. pressure: Equal to same seamless pipe

·Surface: Black painting / hot dip galvanized Pickling white, etc.

·Size range: 1″-24″

description

American butt welding 90 ° elbow (Long radius) is used to connect two pipes by butt welding, so that the pipe changes 90 degrees to change the direction of fluid flow, strong corrosion resistance, high fluid efficiency, safe and reliable structure.

Specification

Available size

| Size | Thickness (mm) | A(mm) | ||||

| NPS | DN | OD (mm) | Sch10 | Sch40 | Sch80 | |

| 1/2″ | 15 | 21.3 | 2.11 | 2.77 | 3.73 | 38 |

| 3/4″ | 20 | 26.7 | 2.11 | 2.87 | 3.91 | 38 |

| 1″ | 25 | 33.4 | 2.77 | 3.38 | 4.55 | 38 |

| 1-1/4″ | 32 | 42.2 | 2.77 | 3.56 | 4.85 | 48 |

| 1-1/2″ | 40 | 48.3 | 2.77 | 3.68 | 5.08 | 57 |

| 2″ | 50 | 60.3 | 2.77 | 3.91 | 5.54 | 76 |

| 2-1/2″ | 65 | 73.0 | 3.05 | 5.16 | 7.01 | 95 |

| 3″ | 80 | 88.9 | 3.05 | 5.49 | 7.62 | 114 |

| 4″ | 100 | 114.3 | 3.05 | 6.02 | 8.56 | 152 |

| 5″ | 125 | 141.3 | 3.40 | 6.55 | 9.53 | 190 |

| 6″ | 150 | 168.3 | 3.40 | 7.11 | 10.97 | 229 |

| 8″ | 200 | 219.1 | 3.76 | 8.18 | 12.70 | 305 |

| 10″ | 250 | 273.0 | 4.19 | 9.27 | 15.09 | 381 |

| 12″ | 300 | 323.8 | 4.57 | 10.31 | 17.48 | 457 |

| 14″ | 350 | 355.6 | 6.35 | 11.13 | 19.05 | 533 |

| 16″ | 400 | 406.4 | 6.35 | 12.70 | 21.44 | 610 |

| 18″ | 450 | 457 | 6.35 | 14.27 | 23.83 | 686 |

| 20″ | 500 | 508 | 6.35 | 15.09 | 26.19 | 762 |

| 24″ | 600 | 610 | 6.35 | 17.48 | 30.96 | 914 |

Note: The thickness is available with Sch5, Sch10, Sch30, Sch40, Sch80, Sch120, Sch160, STD, XS, XXS, 5S, 10S, 40S, 80S, etc.

application

- High-efficiency fluid diversion: Specifically designed for changing the flow direction in pipeline systems, such as chemical plant process pipelines, thermal networks, and oil pipelines, to achieve a smooth 90-degree turn.

- Low-resistance system: Suitable for scenarios requiring smooth fluid flow (such as pump inlets and outlets, main pipeline branches), reducing pressure loss and improving transportation efficiency.

- Suitable for harsh conditions: Corrosion-resistant materials (carbon steel/stainless steel) versions are available for use in chemical, marine, high-temperature, and other corrosive or extreme environments.

- Full size coverage: Supports ½-inch to 24-inch pipes (DN15-DN600), meeting the needs of small equipment to large pipe networks.

advantages

- Streamlined Zero-Loss design -> long-radius bends (1.5 diameters) which reduces turbulence by significant margins, thus lower energy requirement consumption and longevity of the life of pumps & valves

- Good anti-corrosion: carbide/stainless steel with surface treatment (after acid pickling/galvanized) alkali salt anti-corrosion ability, extension of product life by 2 times.

- No leakage hazard: Pipe butt welding completely integrates the pipeline, prevents interface leakage, and is safe to transport hazardous media.

- Permanent system: Welded connections do not need regular maintenance to retighten and, therefore, will have a lower long-term operational cost.

- Broad application range: In line with international standards (ISO/ASME), compatible with global mainstream pipe system.

- Resistant to high pressure and temperature: Meets the line pressure, suitable for severe environments like steam hot oil..

packing

- Rust-proof and impact-resistant packaging:

- Each item is wrapped in rust-proof film + foam corner protectors and placed in a thick corrugated cardboard box (marked: 90° elbow, 6 inches, long radius) .

- Stainless steel products are additionally coated with a scratch-resistant layer.

- Customized solutions for large sizes:

- For 8 inches and above, custom wooden pallets are used, with foam molding securing the curved sections of the elbows to prevent deformation during transportation.

- Efficient ocean freight loading:

- Small sizes are packed in nested boxes, while large sizes are loaded individually on wooden pallets, increasing container space utilization by 40%.

Available size

| Size | Thickness (mm) | A(mm) | ||||

| NPS | DN | OD (mm) | Sch10 | Sch40 | Sch80 | |

| 1/2″ | 15 | 21.3 | 2.11 | 2.77 | 3.73 | 38 |

| 3/4″ | 20 | 26.7 | 2.11 | 2.87 | 3.91 | 38 |

| 1″ | 25 | 33.4 | 2.77 | 3.38 | 4.55 | 38 |

| 1-1/4″ | 32 | 42.2 | 2.77 | 3.56 | 4.85 | 48 |

| 1-1/2″ | 40 | 48.3 | 2.77 | 3.68 | 5.08 | 57 |

| 2″ | 50 | 60.3 | 2.77 | 3.91 | 5.54 | 76 |

| 2-1/2″ | 65 | 73.0 | 3.05 | 5.16 | 7.01 | 95 |

| 3″ | 80 | 88.9 | 3.05 | 5.49 | 7.62 | 114 |

| 4″ | 100 | 114.3 | 3.05 | 6.02 | 8.56 | 152 |

| 5″ | 125 | 141.3 | 3.40 | 6.55 | 9.53 | 190 |

| 6″ | 150 | 168.3 | 3.40 | 7.11 | 10.97 | 229 |

| 8″ | 200 | 219.1 | 3.76 | 8.18 | 12.70 | 305 |

| 10″ | 250 | 273.0 | 4.19 | 9.27 | 15.09 | 381 |

| 12″ | 300 | 323.8 | 4.57 | 10.31 | 17.48 | 457 |

| 14″ | 350 | 355.6 | 6.35 | 11.13 | 19.05 | 533 |

| 16″ | 400 | 406.4 | 6.35 | 12.70 | 21.44 | 610 |

| 18″ | 450 | 457 | 6.35 | 14.27 | 23.83 | 686 |

| 20″ | 500 | 508 | 6.35 | 15.09 | 26.19 | 762 |

| 24″ | 600 | 610 | 6.35 | 17.48 | 30.96 | 914 |

Note: The thickness is available with Sch5, Sch10, Sch30, Sch40, Sch80, Sch120, Sch160, STD, XS, XXS, 5S, 10S, 40S, 80S, etc.

- High-efficiency fluid diversion: Specifically designed for changing the flow direction in pipeline systems, such as chemical plant process pipelines, thermal networks, and oil pipelines, to achieve a smooth 90-degree turn.

- Low-resistance system: Suitable for scenarios requiring smooth fluid flow (such as pump inlets and outlets, main pipeline branches), reducing pressure loss and improving transportation efficiency.

- Suitable for harsh conditions: Corrosion-resistant materials (carbon steel/stainless steel) versions are available for use in chemical, marine, high-temperature, and other corrosive or extreme environments.

- Full size coverage: Supports ½-inch to 24-inch pipes (DN15-DN600), meeting the needs of small equipment to large pipe networks.

- Streamlined Zero-Loss design -> long-radius bends (1.5 diameters) which reduces turbulence by significant margins, thus lower energy requirement consumption and longevity of the life of pumps & valves

- Good anti-corrosion: carbide/stainless steel with surface treatment (after acid pickling/galvanized) alkali salt anti-corrosion ability, extension of product life by 2 times.

- No leakage hazard: Pipe butt welding completely integrates the pipeline, prevents interface leakage, and is safe to transport hazardous media.

- Permanent system: Welded connections do not need regular maintenance to retighten and, therefore, will have a lower long-term operational cost.

- Broad application range: In line with international standards (ISO/ASME), compatible with global mainstream pipe system.

- Resistant to high pressure and temperature: Meets the line pressure, suitable for severe environments like steam hot oil..

- Rust-proof and impact-resistant packaging:

- Each item is wrapped in rust-proof film + foam corner protectors and placed in a thick corrugated cardboard box (marked: 90° elbow, 6 inches, long radius) .

- Stainless steel products are additionally coated with a scratch-resistant layer.

- Customized solutions for large sizes:

- For 8 inches and above, custom wooden pallets are used, with foam molding securing the curved sections of the elbows to prevent deformation during transportation.

- Efficient ocean freight loading:

- Small sizes are packed in nested boxes, while large sizes are loaded individually on wooden pallets, increasing container space utilization by 40%.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.