HOT PRODUCTS TAGS

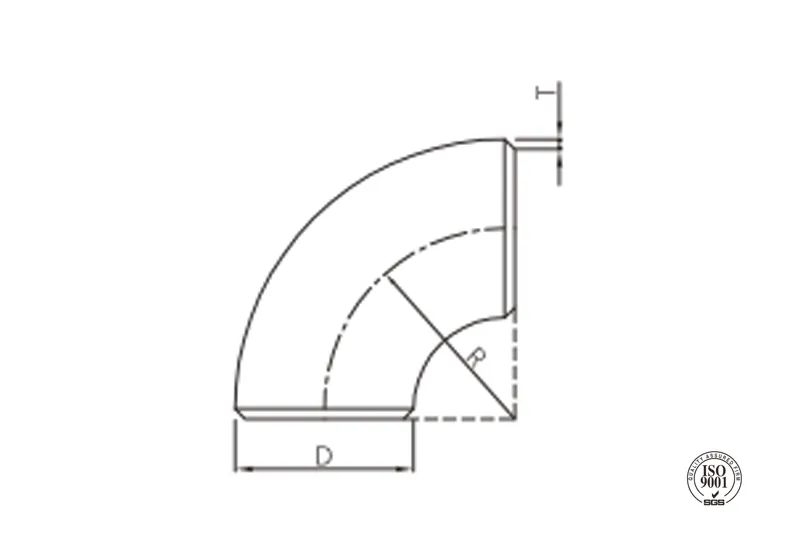

Butt weld 90° elbow (Short radius)

·Standard: ISO

EN 10253-1 / EN 10253-2 / EN 10253-3

·Material: Carbon steel S235 / P235TR2

SS equivalent to WP304 / WP316L

·Type: Short radius, 2D, R=1.0D

·W. pressure: Equal to same straight pipe

·Surface: Black painting / hot dip galvanized

Pickling white, etc.

·Size range: 1″-24″

description

butt weld 90 ° elbow (short radius), significantly reducing fluid resistance and energy loss, combined with butt weld connection to ensure high sealing and structural strength.

Specification

Available size

| Size | Preferred T to EN 10253-2(mm) | R(mm) | ||

| NPS | DN | OD(mm) | ||

| 1/2″ | 15 | 21.3 | 2.0/2.6/3.214.0/5.0/7.1 | 25 |

| 3/4″ | 20 | 26.9 | 2.3/2.6/3.214.014.5/5.6/8.0 | 25 |

| 1″ | 25 | 33.7 | 2.6/3.2/4.0/4.5/5.6/6.3/8.8 | 25 |

| 1-1/4″ | 32 | 42.4 | 2.6/3.6/4.0/5.0/6.3/8.0/10.0 | 32 |

| 1-1/2″ | 40 | 48.3 | 2.6/3.6/4.0/5.0/6.3/8.0/10.0 | 38 |

| 2″ | 50 | 60.3 | 2.9/3.614.0/5.6/7.1/8.8/11.0 | 51 |

| 2-1/2″ | 65 | 76.1 | 2.9/3.6/5.617.1/8.0/10.0/14.2 | 63 |

| 3″ | 80 | 88.9 | 3.214.0/5.6/8.0/8.8/11.0/16.0 | 76 |

| 4″ | 100 | 114.3 | 3.6/4.5/6.3/8.8/11.0/14.2/17.5 | 102 |

| 5″ | 125 | 139.7 | 4.0/5.0/6.3/10.0/12.5/16.0/20.0 | 127 |

| 6″ | 150 | 165.1/168.3 | 4.0/4.5/5.6/7.1/11.0/14.2/17.5122.2 | 152 |

| 8″ | 200 | 219.1 | 4.5/6.3/7.1/8.0/12.5/16.0/17.5/22.2 | 203 |

| 10″ | 250 | 273.0 | 5.0/6.3/8.8/10.0/12.5/16.0/22.2/30.0 | 254 |

| 12″ | 300 | 323.9 | 5.6/7.1/8.8/10.0/12.5/17.5/25.0/32.0 | 305 |

| 14″ | 350 | 355.6 | 5.6/8.0/10.0/12.5/16.0/20.0/28.0/36.0 | 356 |

| 16″ | 400 | 406.4 | 6.3/8.8/10.0/12.5/17.5/22.2/30.0/40.0 | 406 |

| 18″ | 450 | 457 | 6.3/10.0/11.0/12.5/17.5/22.2/32.0/45.0 | 457 |

| 20″ | 500 | 508 | 6.3/10.0/11.0/12.5/17.5/25.0/36.0/50.0 | 508 |

| 24″ | 600 | 610 | 6.3/10.0/12.5/17.5/25.0/30.0/45.0/60.0 | 610 |

application

- Used to change the direction of pipelines by 90 degrees in compact spaces.

- Suitable for industrial piping systems requiring efficient flow and robust connections, such as in chemical plants, oil & gas facilities, power generation, water treatment, and shipbuilding.

- Ideal for applications where space constraints make long-radius elbows impractical.

advantages

- Reduced Flow Resistance: Lower Flow Resistance Short Radius Design Dramatically Reduces Fluid Resistance And Energy Loss Compared With Long Radius.

- Reliable Connection: Butt weld connection forms a good seal and has high strength in factry-made safe and non-leak welded joint.

- Small Space Requirement Compact short radius (R=1.0D) is suitable for the piping layouts in limited space area.

- Material Flexibility: grade standard (carbon steel – S235/P235TR2) and grade corrosion resistant stee Ls (stainless steel – ‘equivalent’ to WP304/WP316L).

- Surface Finish Alternatives: Can be supplied with black finish, hot dip galvanized, or pickled (white) surfaces provide better corrosion resistance and extend the service life.

- Pressure Ratings: Rated as pressure-assisted straight pipe. A size range of 1 inch to 24 inches (NPS) that covers a great breadth of piping requirements .

packing

- Standard export packaging using robust wooden crates or plywood cases for optimal protection during transit.

- Smaller sizes may be packed securely in strong cardboard cartons.

- Internal protective measures (e.g., anti-rust paper, caps/plugs on ends) are employed to prevent damage and corrosion.

- Packages are clearly marked with product identification, size, material, quantity, and handling instructions.

Available size

| Size | Preferred T to EN 10253-2(mm) | R(mm) | ||

| NPS | DN | OD(mm) | ||

| 1/2″ | 15 | 21.3 | 2.0/2.6/3.214.0/5.0/7.1 | 25 |

| 3/4″ | 20 | 26.9 | 2.3/2.6/3.214.014.5/5.6/8.0 | 25 |

| 1″ | 25 | 33.7 | 2.6/3.2/4.0/4.5/5.6/6.3/8.8 | 25 |

| 1-1/4″ | 32 | 42.4 | 2.6/3.6/4.0/5.0/6.3/8.0/10.0 | 32 |

| 1-1/2″ | 40 | 48.3 | 2.6/3.6/4.0/5.0/6.3/8.0/10.0 | 38 |

| 2″ | 50 | 60.3 | 2.9/3.614.0/5.6/7.1/8.8/11.0 | 51 |

| 2-1/2″ | 65 | 76.1 | 2.9/3.6/5.617.1/8.0/10.0/14.2 | 63 |

| 3″ | 80 | 88.9 | 3.214.0/5.6/8.0/8.8/11.0/16.0 | 76 |

| 4″ | 100 | 114.3 | 3.6/4.5/6.3/8.8/11.0/14.2/17.5 | 102 |

| 5″ | 125 | 139.7 | 4.0/5.0/6.3/10.0/12.5/16.0/20.0 | 127 |

| 6″ | 150 | 165.1/168.3 | 4.0/4.5/5.6/7.1/11.0/14.2/17.5122.2 | 152 |

| 8″ | 200 | 219.1 | 4.5/6.3/7.1/8.0/12.5/16.0/17.5/22.2 | 203 |

| 10″ | 250 | 273.0 | 5.0/6.3/8.8/10.0/12.5/16.0/22.2/30.0 | 254 |

| 12″ | 300 | 323.9 | 5.6/7.1/8.8/10.0/12.5/17.5/25.0/32.0 | 305 |

| 14″ | 350 | 355.6 | 5.6/8.0/10.0/12.5/16.0/20.0/28.0/36.0 | 356 |

| 16″ | 400 | 406.4 | 6.3/8.8/10.0/12.5/17.5/22.2/30.0/40.0 | 406 |

| 18″ | 450 | 457 | 6.3/10.0/11.0/12.5/17.5/22.2/32.0/45.0 | 457 |

| 20″ | 500 | 508 | 6.3/10.0/11.0/12.5/17.5/25.0/36.0/50.0 | 508 |

| 24″ | 600 | 610 | 6.3/10.0/12.5/17.5/25.0/30.0/45.0/60.0 | 610 |

- Used to change the direction of pipelines by 90 degrees in compact spaces.

- Suitable for industrial piping systems requiring efficient flow and robust connections, such as in chemical plants, oil & gas facilities, power generation, water treatment, and shipbuilding.

- Ideal for applications where space constraints make long-radius elbows impractical.

- Reduced Flow Resistance: Lower Flow Resistance Short Radius Design Dramatically Reduces Fluid Resistance And Energy Loss Compared With Long Radius.

- Reliable Connection: Butt weld connection forms a good seal and has high strength in factry-made safe and non-leak welded joint.

- Small Space Requirement Compact short radius (R=1.0D) is suitable for the piping layouts in limited space area.

- Material Flexibility: grade standard (carbon steel – S235/P235TR2) and grade corrosion resistant stee Ls (stainless steel – ‘equivalent’ to WP304/WP316L).

- Surface Finish Alternatives: Can be supplied with black finish, hot dip galvanized, or pickled (white) surfaces provide better corrosion resistance and extend the service life.

- Pressure Ratings: Rated as pressure-assisted straight pipe. A size range of 1 inch to 24 inches (NPS) that covers a great breadth of piping requirements .

- Standard export packaging using robust wooden crates or plywood cases for optimal protection during transit.

- Smaller sizes may be packed securely in strong cardboard cartons.

- Internal protective measures (e.g., anti-rust paper, caps/plugs on ends) are employed to prevent damage and corrosion.

- Packages are clearly marked with product identification, size, material, quantity, and handling instructions.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.