HOT PRODUCTS TAGS

Butt weld 90° reducing elbow

·Standard: ISO

EN 10253-1 / EN 10253-2 / EN 10253-3

·Material: Carbon steel S235 / P235TR2

SS equivalent to WP304 / WP316L

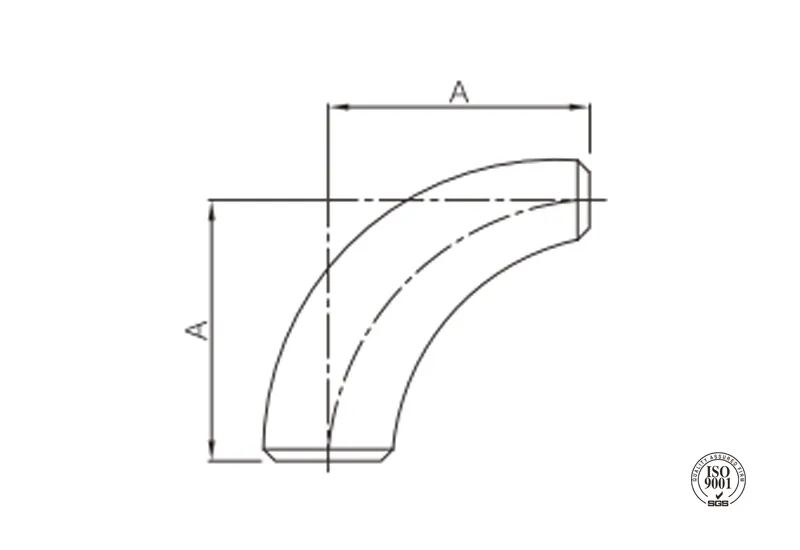

·Type: Long radius, 3D, R=1.5D

·W. pressure: Equal to same straight pipe

·Surface: Black painting / hot dip galvanized

Pickling white, etc.

·Size range: 2″x1-1/2″—24″x12″

description

butt weld 90 ° reducing elbow achieves high-strength sealing and smooth steering through an integrated welding structure, while taking into account the variable diameter function in a compact design, significantly reducing system pressure loss and improving space adaptability.

Specification

Available size

| Size | Preferred T to EN 10253-2 (Large end,mm) | A(mm) | ||

| NPS | DN | OD(mm) | ||

| 2″x1-1/2″ | 50×40 | 60.3×48.3 | 2.9/3.6/4.0/5.6/7.1/8.8/11.0 | 76 |

| 2″x1-1/4″ | 50×32 | 60.3×42.2 | 2.9/3.6/4.0/5.6/7.1/8.8/11.0 | 76 |

| 2″x1″ | 50×25 | 60.3×33.4 | 2.9/3.6/4.0/5.6/7.1/8.8/11.0 | 76 |

| 2-1/2″x2″ | 65×50 | 76.1×60.3 | 2.9/3.6/5.6/7.1/8.0/10.0/14.2 | 95 |

| 2-1/2″x 1-1/2″ | 65×40 | 76.1×48.3 | 2.9/3.6/5.6/7.1/8.0/10.0/14.2 | 95 |

| 2-1/2″x 1-1/4″ | 65×32 | 76.1×42.2 | 2.9/3.6/5.6/7.1/8.0/10.0/14.2 | 95 |

| 3″x2-1/2″ | 80×65 | 88.9×76.1 | 3.214.0/5.6/8.0/8.8/11.0/16.0 | 114 |

| 3″x2″ | 80×50 | 88.9×60.3 | 3.214.0/5.6/8.0/8.8/11.0/16.0 | 114 |

| 3″x1-1/2″ | 80×40 | 88.9×48.3 | 3.214.0/5.6/8.0/8.8/11.0/16.0 | 114 |

| 4″x3″ | 100×80 | 114.3×88.9 | 3.614.5/6.3/8.8/11.0/14.2/17.5 | 152 |

| 4″x2-1/2″ | 100×65 | 114.3×76.1 | 3.6/4.5/6.3/8.8/11.0/14.2/17.5 | 142 |

| 4″x2″ | 100×50 | 114.3×60.3 | 3.6/4.5/6.3/8.8/11.0/14.2/17.5 | 142 |

| 5″x4″ | 125×100 | 141.3×114.3 | 4.0/5.0/6.3/10.0/12.5/16.0/20.0 | 190 |

| 5″x3″ | 125×80 | 141.3×88.9 | 4.0/5.0/6.3/10.0/12.5/16.0/20.0 | 190 |

| 5″x2-1/2″ | 125×65 | 141.3×76.1 | 4.0/5.0/6.3/10.0/12.5/16.0/20.0 | 190 |

| 6″x5″ | 150×125 | 168.3×141.3 | 4.0/4.5/5.6/7.1/11.0/14.2/17.5122.2 | 229 |

| 6″x4″ | 150×100 | 168.3×114.3 | 4.0/4.515.6/7.1/11.0/14.2/17.5122.2 | 229 |

| 6″x3″ | 150×80 | 168.3×88.9 | 4.0/4.5/5.6/7.1/11.0/14.2/17.5/22.2 | 229 |

| 8″x6″ | 200×150 | 219.1×168.3 | 4.5/6.317.1/8.0/12.5/16.0/17.5/22.2 | 305 |

| 8″x5″ | 200×125 | 219.1×141.3 | 4.5/6.317.1/8.0/12.5/16.0/17.5/22.2 | 305 |

| 8″x 4″ | 200×100 | 219.1×114.3 | 4.5/6.317.1/8.0/12.5/16.0/17.5/22.2 | 305 |

| 10″x8″ | 250×200 | 273.0×219.1 | 5.0/6.3/8.8/10.0/12.5/16.0/22.2/30.0 | 381 |

| 10″x6″ | 250×150 | 273.0×168.3 | 5.0/6.3/8.8/10.0/12.5/16.0/22.2/30.0 | 381 |

| 10″x5″ | 250×125 | 273.0×141.3 | 5.0/6.3/8.8/10.0/12.5/16.0/22.2/30.0 | 381 |

| 12″x10″ | 300×250 | 323.8×273 | 5.6/7.1/8.8/10.0/12.5/17.5/25.0/32.0 | 457 |

| 12″x8″ | 300×200 | 323.8×219.1 | 5.6/7.1/8.8/10.0/12.5/17.5/25.0/32.0 | 457 |

| 12″x6″ | 300×150 | 323.8×168.3 | 5.6/7.1/8.8/10.0/12.5/17.5/25.0/32.0 | 457 |

| 14″x12″ | 350×300 | 355.6×323.8 | 5.6/8.0/10.0/12.5/16.0/20.0/28.0/36.0 | 533 |

| 14″x10″ | 350×250 | 355.6×273 | 5.6/8.0/10.0/12.5/16.0/20.0/28.0/36.0 | 533 |

| 14″x8″ | 350×200 | 355.6×219.1 | 5.6/8.0/10.0/12.5/16.0/20.0/28.0/36.0 | 533 |

| 16″x14″ | 400×350 | 406.4×355.6 | 6.3/8.8/10.0/12.5/17.5122.2/30.0/40.0 | 610 |

| 16″x12″ | 400×300 | 406.4×323.8 | 6.3/8.8/10.0/12.5/17.5/22.2/30.0/40.0 | 610 |

| 16″x 10″ | 400×250 | 406.4×273 | 6.3/8.8/10.0/12.5/17.5122.2/30.0/40.0 | 610 |

| 18″x 16″ | 450×400 | 457×406.4 | 6.3/10.0/11.0/12.5/17.5/22.2/32.0/45.0 | 686 |

| 18″x 14″ | 450×350 | 457×355.6 | 6.3/10.0/11.0/12.5/17.5/22.2/32.0/45.0 | 686 |

| 18″x 12″ | 450×300 | 457×323.8 | 6.3/10.0/11.0/12.5/17.5/22.2/32.0145.0 | 686 |

| 18″x 10″ | 450×250 | 457×273 | 6.3/10.0/11.0/12.5/17.5/22.2/32.0/45.0 | 686 |

| 20″x 18″ | 500×450 | 508×457 | 6.3/10.0/11.0/12.5/17.5/25.0/36.0/50.0 | 762 |

| 20″x 16″ | 500×400 | 508×406.4 | 6.3/10.0/11.0/12.5/17.5/25.0/36.0/50.0 | 762 |

| 20″x 14″ | 500×350 | 508×355.6 | 6.3/10.0/11.0/12.5/17.5/25.0/36.0/50.0 | 762 |

| 20″x12″ | 500×300 | 508×323.8 | 6.3/10.0/11.0/12.5/17.5/25.0/36.0/50.0 | 762 |

| 20″x10″ | 500×250 | 508×273 | 6.3/10.0/11.0/12.5/17.5/25.0/36.0/50.0 | 762 |

| 24″x 22″ | 600×550 | 610×559 | 6.3/10.0/12.5/17.5/25.0/30.0/45.0/60.0 | 914 |

| 24″x20″ | 600×500 | 610×508 | 6.3/10.0/12.5/17.5/25.0/30.0/45.0/60.0 | 914 |

| 24″x18″ | 600×450 | 610×457 | 6.3/10.0/12.5/17.5/25.0/30.0145.0/60.0 | 914 |

| 24″x 16″ | 600×400 | 610×406.4 | 6.3/10.0/12.5/17.5/25.0/30.0/45.0/60.0 | 914 |

| 24″x14″ | 600×350 | 610×355.6 | 6.3/10.0/12.5/17.5/25.0/30.0/45.0/60.0 | 914 |

| 24″x12″ | 600×300 | 610×323.8 | 6.3/10.0/12.5/17.5/25.0/30.0145.0/60.0 | 914 |

Note:

- The thickness of above form refers to large end OD, and thickness of small end OD is different.

- For size DN 150, it is also available with 165.1 mm as per EN 10255.

application

- Specifically designed for space-constrained pipe diameter changes, it simultaneously achieves 90° directional adjustment and pipe diameter conversion, breaking through the layout restrictions of traditional elbow + reducer pipes.

- Key applications include compact equipment interfaces (such as pump valve assemblies, heat exchangers), ship engine room pipes, and prefabricated systems in modular factories, among other complex space scenarios.

- In pipeline renovation projects, it replaces multi-component assembly solutions, reducing installation space by 50%.

advantages

- Revolution of Space Effects: Dual-actionIntegrated ElbowReducer An all-in-one combines the usual elbows and reducers into one component. The long radius design (R=1.5D) ensures low flow resistance, and makes the most effective use of installation space.

- Projectiles With Pressure: Integrally forged construction + fully welded joints can contain pressure equivalent to that of straight pipes and remove the risk of joint leakage.

- Smart Flow Channel Design: The gradual cross-section technology reduces 35% of the turbulence, which greatly decreases the loss of system energy.

- Corrosion protection system (double anti-corrosion material): Inner tank: carbon steel-inner hot-dip galvanized (salt spary resistance 1000h) or inner epoxy coal taring (acid and alkali resistant). Stainless steel: Prohibited Pickling and passivation with acid, should be in strict conformity with ASME B31. 3)

- Installation Efficiency Upgrade: 60% reduction in the number of welds, reducing construction time by 40%, especially for high-altitude/constrained space operation.

- Covers Full Operating Condition: all specifications from 2“×1-1/2” to 24“×12”, compatible with SCH XXS pipes and other extreme thick walled pipes .

packing

- Asymmetric protection system:

- Use irregular foam molds to precisely fix variable diameter curved surfaces.

- Mark the outer box with a “large diameter end →” direction indicator.

- Dual diameter dedicated protection:

- Large diameter end: steel flange cover + rubber buffer ring.

- Small diameter end: engineering plastic screw-in protective cover.

- Marine-grade anti-rust solution:

- Carbon steel parts: VCI vapor phase anti-rust bag + anti-rust oil coating.

- Stainless steel components: Vacuum-sealed aluminum foil packaging + desiccant

Available size

| Size | Preferred T to EN 10253-2 (Large end,mm) | A(mm) | ||

| NPS | DN | OD(mm) | ||

| 2″x1-1/2″ | 50×40 | 60.3×48.3 | 2.9/3.6/4.0/5.6/7.1/8.8/11.0 | 76 |

| 2″x1-1/4″ | 50×32 | 60.3×42.2 | 2.9/3.6/4.0/5.6/7.1/8.8/11.0 | 76 |

| 2″x1″ | 50×25 | 60.3×33.4 | 2.9/3.6/4.0/5.6/7.1/8.8/11.0 | 76 |

| 2-1/2″x2″ | 65×50 | 76.1×60.3 | 2.9/3.6/5.6/7.1/8.0/10.0/14.2 | 95 |

| 2-1/2″x 1-1/2″ | 65×40 | 76.1×48.3 | 2.9/3.6/5.6/7.1/8.0/10.0/14.2 | 95 |

| 2-1/2″x 1-1/4″ | 65×32 | 76.1×42.2 | 2.9/3.6/5.6/7.1/8.0/10.0/14.2 | 95 |

| 3″x2-1/2″ | 80×65 | 88.9×76.1 | 3.214.0/5.6/8.0/8.8/11.0/16.0 | 114 |

| 3″x2″ | 80×50 | 88.9×60.3 | 3.214.0/5.6/8.0/8.8/11.0/16.0 | 114 |

| 3″x1-1/2″ | 80×40 | 88.9×48.3 | 3.214.0/5.6/8.0/8.8/11.0/16.0 | 114 |

| 4″x3″ | 100×80 | 114.3×88.9 | 3.614.5/6.3/8.8/11.0/14.2/17.5 | 152 |

| 4″x2-1/2″ | 100×65 | 114.3×76.1 | 3.6/4.5/6.3/8.8/11.0/14.2/17.5 | 142 |

| 4″x2″ | 100×50 | 114.3×60.3 | 3.6/4.5/6.3/8.8/11.0/14.2/17.5 | 142 |

| 5″x4″ | 125×100 | 141.3×114.3 | 4.0/5.0/6.3/10.0/12.5/16.0/20.0 | 190 |

| 5″x3″ | 125×80 | 141.3×88.9 | 4.0/5.0/6.3/10.0/12.5/16.0/20.0 | 190 |

| 5″x2-1/2″ | 125×65 | 141.3×76.1 | 4.0/5.0/6.3/10.0/12.5/16.0/20.0 | 190 |

| 6″x5″ | 150×125 | 168.3×141.3 | 4.0/4.5/5.6/7.1/11.0/14.2/17.5122.2 | 229 |

| 6″x4″ | 150×100 | 168.3×114.3 | 4.0/4.515.6/7.1/11.0/14.2/17.5122.2 | 229 |

| 6″x3″ | 150×80 | 168.3×88.9 | 4.0/4.5/5.6/7.1/11.0/14.2/17.5/22.2 | 229 |

| 8″x6″ | 200×150 | 219.1×168.3 | 4.5/6.317.1/8.0/12.5/16.0/17.5/22.2 | 305 |

| 8″x5″ | 200×125 | 219.1×141.3 | 4.5/6.317.1/8.0/12.5/16.0/17.5/22.2 | 305 |

| 8″x 4″ | 200×100 | 219.1×114.3 | 4.5/6.317.1/8.0/12.5/16.0/17.5/22.2 | 305 |

| 10″x8″ | 250×200 | 273.0×219.1 | 5.0/6.3/8.8/10.0/12.5/16.0/22.2/30.0 | 381 |

| 10″x6″ | 250×150 | 273.0×168.3 | 5.0/6.3/8.8/10.0/12.5/16.0/22.2/30.0 | 381 |

| 10″x5″ | 250×125 | 273.0×141.3 | 5.0/6.3/8.8/10.0/12.5/16.0/22.2/30.0 | 381 |

| 12″x10″ | 300×250 | 323.8×273 | 5.6/7.1/8.8/10.0/12.5/17.5/25.0/32.0 | 457 |

| 12″x8″ | 300×200 | 323.8×219.1 | 5.6/7.1/8.8/10.0/12.5/17.5/25.0/32.0 | 457 |

| 12″x6″ | 300×150 | 323.8×168.3 | 5.6/7.1/8.8/10.0/12.5/17.5/25.0/32.0 | 457 |

| 14″x12″ | 350×300 | 355.6×323.8 | 5.6/8.0/10.0/12.5/16.0/20.0/28.0/36.0 | 533 |

| 14″x10″ | 350×250 | 355.6×273 | 5.6/8.0/10.0/12.5/16.0/20.0/28.0/36.0 | 533 |

| 14″x8″ | 350×200 | 355.6×219.1 | 5.6/8.0/10.0/12.5/16.0/20.0/28.0/36.0 | 533 |

| 16″x14″ | 400×350 | 406.4×355.6 | 6.3/8.8/10.0/12.5/17.5122.2/30.0/40.0 | 610 |

| 16″x12″ | 400×300 | 406.4×323.8 | 6.3/8.8/10.0/12.5/17.5/22.2/30.0/40.0 | 610 |

| 16″x 10″ | 400×250 | 406.4×273 | 6.3/8.8/10.0/12.5/17.5122.2/30.0/40.0 | 610 |

| 18″x 16″ | 450×400 | 457×406.4 | 6.3/10.0/11.0/12.5/17.5/22.2/32.0/45.0 | 686 |

| 18″x 14″ | 450×350 | 457×355.6 | 6.3/10.0/11.0/12.5/17.5/22.2/32.0/45.0 | 686 |

| 18″x 12″ | 450×300 | 457×323.8 | 6.3/10.0/11.0/12.5/17.5/22.2/32.0145.0 | 686 |

| 18″x 10″ | 450×250 | 457×273 | 6.3/10.0/11.0/12.5/17.5/22.2/32.0/45.0 | 686 |

| 20″x 18″ | 500×450 | 508×457 | 6.3/10.0/11.0/12.5/17.5/25.0/36.0/50.0 | 762 |

| 20″x 16″ | 500×400 | 508×406.4 | 6.3/10.0/11.0/12.5/17.5/25.0/36.0/50.0 | 762 |

| 20″x 14″ | 500×350 | 508×355.6 | 6.3/10.0/11.0/12.5/17.5/25.0/36.0/50.0 | 762 |

| 20″x12″ | 500×300 | 508×323.8 | 6.3/10.0/11.0/12.5/17.5/25.0/36.0/50.0 | 762 |

| 20″x10″ | 500×250 | 508×273 | 6.3/10.0/11.0/12.5/17.5/25.0/36.0/50.0 | 762 |

| 24″x 22″ | 600×550 | 610×559 | 6.3/10.0/12.5/17.5/25.0/30.0/45.0/60.0 | 914 |

| 24″x20″ | 600×500 | 610×508 | 6.3/10.0/12.5/17.5/25.0/30.0/45.0/60.0 | 914 |

| 24″x18″ | 600×450 | 610×457 | 6.3/10.0/12.5/17.5/25.0/30.0145.0/60.0 | 914 |

| 24″x 16″ | 600×400 | 610×406.4 | 6.3/10.0/12.5/17.5/25.0/30.0/45.0/60.0 | 914 |

| 24″x14″ | 600×350 | 610×355.6 | 6.3/10.0/12.5/17.5/25.0/30.0/45.0/60.0 | 914 |

| 24″x12″ | 600×300 | 610×323.8 | 6.3/10.0/12.5/17.5/25.0/30.0145.0/60.0 | 914 |

Note:

- The thickness of above form refers to large end OD, and thickness of small end OD is different.

- For size DN 150, it is also available with 165.1 mm as per EN 10255.

- Specifically designed for space-constrained pipe diameter changes, it simultaneously achieves 90° directional adjustment and pipe diameter conversion, breaking through the layout restrictions of traditional elbow + reducer pipes.

- Key applications include compact equipment interfaces (such as pump valve assemblies, heat exchangers), ship engine room pipes, and prefabricated systems in modular factories, among other complex space scenarios.

- In pipeline renovation projects, it replaces multi-component assembly solutions, reducing installation space by 50%.

- Revolution of Space Effects: Dual-actionIntegrated ElbowReducer An all-in-one combines the usual elbows and reducers into one component. The long radius design (R=1.5D) ensures low flow resistance, and makes the most effective use of installation space.

- Projectiles With Pressure: Integrally forged construction + fully welded joints can contain pressure equivalent to that of straight pipes and remove the risk of joint leakage.

- Smart Flow Channel Design: The gradual cross-section technology reduces 35% of the turbulence, which greatly decreases the loss of system energy.

- Corrosion protection system (double anti-corrosion material): Inner tank: carbon steel-inner hot-dip galvanized (salt spary resistance 1000h) or inner epoxy coal taring (acid and alkali resistant). Stainless steel: Prohibited Pickling and passivation with acid, should be in strict conformity with ASME B31. 3)

- Installation Efficiency Upgrade: 60% reduction in the number of welds, reducing construction time by 40%, especially for high-altitude/constrained space operation.

- Covers Full Operating Condition: all specifications from 2“×1-1/2” to 24“×12”, compatible with SCH XXS pipes and other extreme thick walled pipes .

- Asymmetric protection system:

- Use irregular foam molds to precisely fix variable diameter curved surfaces.

- Mark the outer box with a “large diameter end →” direction indicator.

- Dual diameter dedicated protection:

- Large diameter end: steel flange cover + rubber buffer ring.

- Small diameter end: engineering plastic screw-in protective cover.

- Marine-grade anti-rust solution:

- Carbon steel parts: VCI vapor phase anti-rust bag + anti-rust oil coating.

- Stainless steel components: Vacuum-sealed aluminum foil packaging + desiccant

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.