HOT PRODUCTS TAGS

Butt weld cap

·Standard: ISO

ASME B16.9

·Material: Carbon steel ASTM A234, WPB

SS ASTM A403, WP304 / WP316L

·W. pressure: Equal to same seamless pipe

·Surface: Black painting / hot dip galvanized Pickling white, etc.

·Size range: 1″-24″

description

butt weld caps are installed at the end of the pipeline through butt welded connections to plug the pipeline and form a liquid-tight or air-tight seal, with a firm structure and easy installation.

Specification

Available size

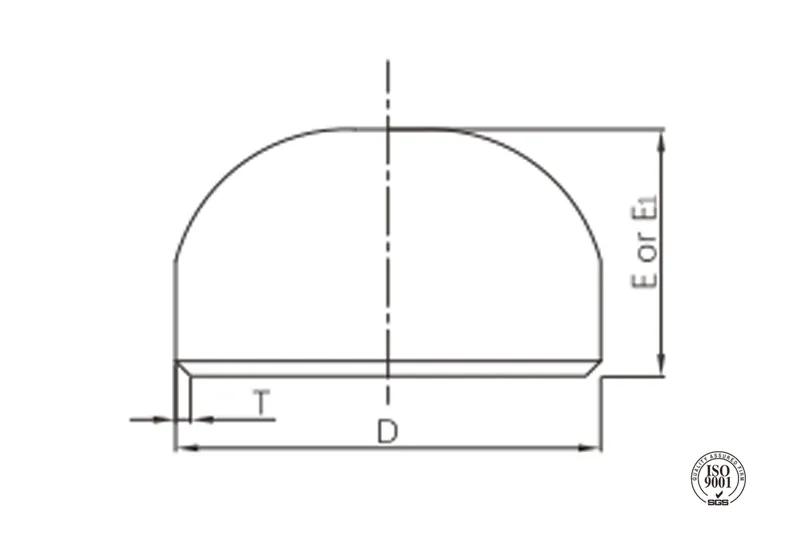

| Size | Thickness(mm) | E (mm) within max T | E1 (mm) for greater T | |||||

| NPS | DN | OD(mm) | Sch10 | Sch40 | Sch80 | E | Max T | |

| 1/2″ | 15 | 21.3 | 2.11 | 2.77 | 3.73 | 25 | 4.57 | 25 |

| 3/4″ | 20 | 26.7 | 2.11 | 2.87 | 3.91 | 25 | 3.81 | 25 |

| 1″ | 25 | 33.4 | 2.77 | 3.38 | 4.55 | 38 | 4.57 | 38 |

| 1-1/4″ | 32 | 42.2 | 2.77 | 3.56 | 4.85 | 38 | 4.83 | 38 |

| 1-1/2″ | 40 | 48.3 | 2.77 | 3.68 | 5.08 | 38 | 5.08 | 38 |

| 2″ | 50 | 60.3 | 2.77 | 3.91 | 5.54 | 38 | 5.59 | 44 |

| 2-1/2″ | 65 | 73.0 | 3.05 | 5.16 | 7.01 | 38 | 7.11 | 51 |

| 3″ | 80 | 88.9 | 3.05 | 5.49 | 7.62 | 51 | 7.62 | 64 |

| 4″ | 100 | 114.3 | 3.05 | 6.02 | 8.56 | 64 | 8.64 | 76 |

| 5″ | 125 | 141.3 | 3.40 | 6.55 | 9.53 | 76 | 9.65 | 89 |

| 6″ | 150 | 168.3 | 3.40 | 7.11 | 10.97 | 89 | 10.92 | 102 |

| 8″ | 200 | 219.1 | 3.76 | 8.18 | 12.70 | 102 | 12.70 | 127 |

| 10″ | 250 | 273.0 | 4.19 | 9.27 | 15.09 | 127 | 12.70 | 152 |

| 12″ | 300 | 323.8 | 4.57 | 10.31 | 17.48 | 152 | 12.70 | 178 |

| 14″ | 350 | 355.6 | 6.35 | 11.13 | 19.05 | 165 | 12.70 | 191 |

| 16″ | 400 | 406.4 | 6.35 | 12.70 | 21.44 | 178 | 12.70 | 203 |

| 18″ | 450 | 457 | 6.35 | 14.27 | 23.83 | 203 | 12.70 | 229 |

| 20″ | 500 | 508 | 6.35 | 15.09 | 26.19 | 229 | 12.70 | 254 |

| 24″ | 600 | 610 | 6.35 | 17.48 | 30.96 | 267 | 12.70 | 305 |

Note: The thickness is available with Sch5, Sch10, Sch30, Sch40, Sch80, Sch120, Sch160, STD, XS, XXS, 5S, 10S, 40S, 80S, etc.

application

- Pipe end sealing: Used to permanently seal pipe ends to prevent media leakage or contamination (such as process pipeline reserved openings and system isolation sections).

- System pressure testing: Provides reliable airtight/liquid seals during pipe pressure testing and equipment maintenance.

- Key protection nodes: High-risk systems requiring explosion protection and leak prevention in chemical, energy, and marine industries (such as reactor outlet and storage tank connection pipes).

advantages

- Guaranteed Sealing: Butt-welding’s while zero leakage sealing, the pressure / vacuum environment can withstand long-term high-pressure conditions. The sealing performance can be equated with that of the pipe body, and it is suitable for use in high-temperature or corrosive media.

- Structural Robustness- Has a pressure-bearing capacity equivalent to seamless steel pipes of the same standard, able to bear water hammer and system vibrating. Those split in hemispherical or butterfly-shaped are designed to optimize stress distribution and prevent local deformation.

- Installation Effiency: The integrated butt-welded joint design that are uniform eliminates the need for flanges or threads, greatly reducing installation complexity. 1”to 24” Full size range, suitable for all kind of pipeline systems.

- Material Versatility: Carbon steel (ASTM A234): the cheapest choice for all standard industrial applications. Stainless steel (304 and 316L): Food-grade with pharmaceutical hygiene standards plus suitable for extremely corrosive environments.

packing

- Dual Protection Strategy:

- Surface Treatment: Black paint anti-rust (standard)/hot-dip galvanizing (outdoor)/acid washing and passivation (stainless steel corrosion protection).

- Structural Protection: Concave curved surfaces filled with soft foam to prevent deformation from collisions during transportation.

- Smart Graded Packaging:

- Small pipe caps (≤8″): Multiple pieces stacked and secured with steel straps into cylindrical units.

- Large pipe caps (>8″): Custom wooden boxes for single pieces, with internal steel frames to secure the center of gravity.

- Misuse prevention labels:

- Prominent labeling on outer boxes with “END CAP” and prohibited installation direction arrows (to prevent reverse welding).

- Attach pressure rating labels (e.g., “Sch40 Compatible”).

Available size

| Size | Thickness(mm) | E (mm) within max T | E1 (mm) for greater T | |||||

| NPS | DN | OD(mm) | Sch10 | Sch40 | Sch80 | E | Max T | |

| 1/2″ | 15 | 21.3 | 2.11 | 2.77 | 3.73 | 25 | 4.57 | 25 |

| 3/4″ | 20 | 26.7 | 2.11 | 2.87 | 3.91 | 25 | 3.81 | 25 |

| 1″ | 25 | 33.4 | 2.77 | 3.38 | 4.55 | 38 | 4.57 | 38 |

| 1-1/4″ | 32 | 42.2 | 2.77 | 3.56 | 4.85 | 38 | 4.83 | 38 |

| 1-1/2″ | 40 | 48.3 | 2.77 | 3.68 | 5.08 | 38 | 5.08 | 38 |

| 2″ | 50 | 60.3 | 2.77 | 3.91 | 5.54 | 38 | 5.59 | 44 |

| 2-1/2″ | 65 | 73.0 | 3.05 | 5.16 | 7.01 | 38 | 7.11 | 51 |

| 3″ | 80 | 88.9 | 3.05 | 5.49 | 7.62 | 51 | 7.62 | 64 |

| 4″ | 100 | 114.3 | 3.05 | 6.02 | 8.56 | 64 | 8.64 | 76 |

| 5″ | 125 | 141.3 | 3.40 | 6.55 | 9.53 | 76 | 9.65 | 89 |

| 6″ | 150 | 168.3 | 3.40 | 7.11 | 10.97 | 89 | 10.92 | 102 |

| 8″ | 200 | 219.1 | 3.76 | 8.18 | 12.70 | 102 | 12.70 | 127 |

| 10″ | 250 | 273.0 | 4.19 | 9.27 | 15.09 | 127 | 12.70 | 152 |

| 12″ | 300 | 323.8 | 4.57 | 10.31 | 17.48 | 152 | 12.70 | 178 |

| 14″ | 350 | 355.6 | 6.35 | 11.13 | 19.05 | 165 | 12.70 | 191 |

| 16″ | 400 | 406.4 | 6.35 | 12.70 | 21.44 | 178 | 12.70 | 203 |

| 18″ | 450 | 457 | 6.35 | 14.27 | 23.83 | 203 | 12.70 | 229 |

| 20″ | 500 | 508 | 6.35 | 15.09 | 26.19 | 229 | 12.70 | 254 |

| 24″ | 600 | 610 | 6.35 | 17.48 | 30.96 | 267 | 12.70 | 305 |

Note: The thickness is available with Sch5, Sch10, Sch30, Sch40, Sch80, Sch120, Sch160, STD, XS, XXS, 5S, 10S, 40S, 80S, etc.

- Pipe end sealing: Used to permanently seal pipe ends to prevent media leakage or contamination (such as process pipeline reserved openings and system isolation sections).

- System pressure testing: Provides reliable airtight/liquid seals during pipe pressure testing and equipment maintenance.

- Key protection nodes: High-risk systems requiring explosion protection and leak prevention in chemical, energy, and marine industries (such as reactor outlet and storage tank connection pipes).

- Guaranteed Sealing: Butt-welding’s while zero leakage sealing, the pressure / vacuum environment can withstand long-term high-pressure conditions. The sealing performance can be equated with that of the pipe body, and it is suitable for use in high-temperature or corrosive media.

- Structural Robustness- Has a pressure-bearing capacity equivalent to seamless steel pipes of the same standard, able to bear water hammer and system vibrating. Those split in hemispherical or butterfly-shaped are designed to optimize stress distribution and prevent local deformation.

- Installation Effiency: The integrated butt-welded joint design that are uniform eliminates the need for flanges or threads, greatly reducing installation complexity. 1”to 24” Full size range, suitable for all kind of pipeline systems.

- Material Versatility: Carbon steel (ASTM A234): the cheapest choice for all standard industrial applications. Stainless steel (304 and 316L): Food-grade with pharmaceutical hygiene standards plus suitable for extremely corrosive environments.

- Dual Protection Strategy:

- Surface Treatment: Black paint anti-rust (standard)/hot-dip galvanizing (outdoor)/acid washing and passivation (stainless steel corrosion protection).

- Structural Protection: Concave curved surfaces filled with soft foam to prevent deformation from collisions during transportation.

- Smart Graded Packaging:

- Small pipe caps (≤8″): Multiple pieces stacked and secured with steel straps into cylindrical units.

- Large pipe caps (>8″): Custom wooden boxes for single pieces, with internal steel frames to secure the center of gravity.

- Misuse prevention labels:

- Prominent labeling on outer boxes with “END CAP” and prohibited installation direction arrows (to prevent reverse welding).

- Attach pressure rating labels (e.g., “Sch40 Compatible”).

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.