HOT PRODUCTS TAGS

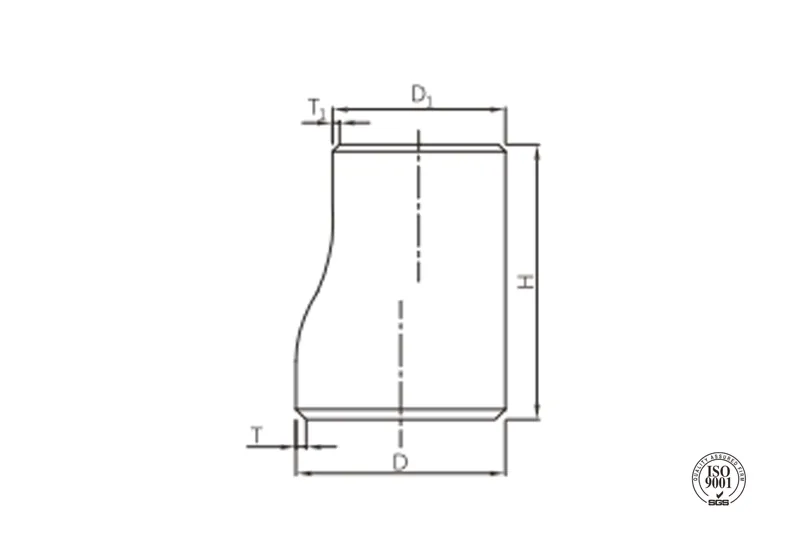

Butt weld eccentric reducer

·Standard: ISO

ASME B16.9

·Material: Carbon steel ASTM A234, WPB

SS ASTM A403, WP304 / WP316L

·W. pressure: Equal to same seamless pipe

·Surface: Black painting / hot dip galvanized

Pickling white,etc.

·Size range: 3/4″x1/2″—24″x10″

description

butt weld eccentric reducer is a conical pipe fitting with a butt welded connection for connecting two pipes of different diameters and different axes, while maintaining structural stability and a smooth fluid transition.

Specification

Available size

| Size(DXD₁) | Thickness TXT₁ (mm) | H (mm) | ||||

| NPS | DN | OD(mm) | Sch10 | Sch40 | Sch80 | |

| 3/4″x1/2″ | 20×15 | 26.7×21.3 | 2.11×2.11 | 2.87×2.77 | 3.91×3.73 | 38 |

| 1″x3/4″ | 25×20 | 33.4×26.7 | 2.77×2.11 | 3.38×2.87 | 4.55×3.91 | 51 |

| 1″x1/2″ | 25×15 | 33.4×21.3 | 2.77×2.11 | 3.38×2.77 | 4.55×3.73 | 51 |

| 1-1/4″x1″ | 32×25 | 42.2×33.4 | 2.77×2.77 | 3.56×3.38 | 4.85×4.55 | 51 |

| 1-1/4″x 3/4″ | 32x 20 | 42.2×26.7 | 2.77×2.11 | 3.56×2.87 | 4.85×3.91 | 51 |

| 1-1/4″x1/2″ | 32x 15 | 42.2×21.3 | 2.77×2.11 | 3.56×2.77 | 4.85×3.73 | 51 |

| 1-1/2″x1-1/4″ | 40×32 | 48.3×42.2 | 2.77×2.77 | 3.68×3.56 | 5.08×4.85 | 64 |

| 1-1/2″x1″ | 40×25 | 48.3×33.4 | 2.77×2.77 | 3.68x 3.38 | 5.08×4.55 | 64 |

| 1-1/2″x 3/4″ | 40×20 | 48.3×26.7 | 2.77×2.11 | 3.68×2.87 | 5.08×3.91 | 64 |

| 1-1/2″x1/2″ | 40×15 | 48.3×21.3 | 2.77×2.11 | 3.68×2.77 | 5.08×3.73 | 64 |

| 2″x1-1/2″ | 50×40 | 60.3×48.3 | 2.77×2.77 | 3.91×3.68 | 5.54×5.08 | 76 |

| 2″x1-1/4″ | 50×32 | 60.3×42.2 | 2.77×2.77 | 3.91×3.56 | 5.54×4.85 | 76 |

| 2″x1″ | 50×25 | 60.3×33.4 | 2.77×2.77 | 3.91x 3.38 | 5.54×4.55 | 76 |

| 2″x3/4″ | 50x 20 | 60.3×26.7 | 2.77×2.11 | 3.91×2.87 | 5.54×3.91 | 76 |

| 2″x1/2″ | 65×50 | 60.3×21.3 | 2.77×2.11 | 3.91×2.77 | 5.54×3.73 | 89 |

| 2-1/2″x2″ | 65×50 | 73.0×60.3 | 3.05×2.77 | 5.16×3.91 | 7.01×5.54 | 89 |

| 2-1/2″x1-1/2″ | 65×40 | 73.0×48.3 | 3.05×2.77 | 5.16×3.68 | 7.01×5.08 | 89 |

| 2-1/2″x1-1/4″ | 65×32 | 73.0×42.2 | 3.05×2.77 | 5.16×3.56 | 7.01×4.85 | 89 |

| 2-1/2″x1″ | 65xx25 | 73.0×33.4 | 3.05×2.77 | 5.16×3.38 | 7.01×4.55 | 89 |

| 2-1/2″x3/4″ | 65×20 | 73.0×26.7 | 3.05×2.11 | 5.16×2.87 | 7.01×3.91 | 89 |

| 3″x2-1/2″ | 80×65 | 88.9×73.0 | 3.05×3.05 | 5.49×5.16 | 7.62×7.01 | 89 |

| 3″x2″ | 80×50 | 88.9×60.3 | 3.05×2.77 | 5.49×3.91 | 7.62×5.54 | 89 |

| 3″x1-1/2″ | 80xx40 | 88.9×48.3 | 3.05×2.77 | 5.49×3.68 | 7.62×5.08 | 89 |

| 3″x1-1/4″ | 80×32 | 88.9×42.2 | 3.05×2.77 | 5.49×3.56 | 7.62×4.85 | 89 |

| 3″x1″ | 80×25 | 88.9×33.4 | 3.05×2.77 | 5.49×3.38 | 7.62×4.55 | 89 |

| 4″x3″ | 100×80 | 114.3×88.9 | 3.05×3.05 | 6.02×5.49 | 8.56×7.62 | 102 |

| 4″x2-1/2″ | 100×65 | 114.3×73.0 | 3.05×3.05 | 6.02×5.16 | 8.56×7.01 | 102 |

| 4″x2″ | 100×50 | 114.3×60.3 | 3.05×2.77 | 6.02×3.91 | 8.56×5.54 | 102 |

| 4″x1-1/2″ | 100×40 | 114.3×48.3 | 3.05×2.77 | 6.02×3.68 | 8.56×5.08 | 102 |

| 4″x1-1/4″ | 100×32 | 114.3×42.2 | 3.05×2.77 | 6.02×3.56 | 8.56×4.85 | 102 |

| 4″x1″ | 100×25 | 114.3×33.4 | 3.05×2.77 | 6.02×3.38 | 8.56×4.55 | 102 |

| 5″x4″ | 125×100 | 141.3×114.3 | 3.40×3.05 | 6.55×6.02 | 9.53×8.56 | 127 |

| 5″x3″ | 125×80 | 141.3×88.9 | 3.40×3.05 | 6.55×5.49 | 9.53×7.62 | 127 |

| 5″x2-1/2″ | 125×65 | 141.3×73.0 | 3.40×3.05 | 6.55×5.16 | 9.53×7.01 | 127 |

| 5″x2″ | 125×50 | 141.3×60.3 | 3.40×2.77 | 6.55×3.91 | 9.53×5.54 | 127 |

| 6″x5″ | 150×125 | 168.3×141.3 | 3.40×3.40 | 7.11×6.55 | 10.97×9.53 | 140 |

| 6″x4″ | 150×100 | 168.3×114.3 | 3.40×3.05 | 7.11×6.02 | 10.97×8.56 | 140 |

| 6″x3″ | 150×80 | 168.3×88.9 | 3.40×3.05 | 7.11×5.49 | 10.97×7.62 | 140 |

| 6″x2-1/2″ | 150×65 | 168.3×73.0 | 3.40×3.05 | 7.11×5.16 | 10.97×7.01 | 140 |

| 6″x2″ | 150×50 | 168.3×60.3 | 3.40×2.77 | 7.11×3.91 | 10.97×5.54 | 140 |

| 8″x6″ | 200×150 | 219.1×168.3 | 3.76×3.40 | 8.18×7.11 | 12.70×10.97 | 152 |

| 8″x5″ | 200×125 | 219.1×141.3 | 3.76×3.40 | 8.18×6.55 | 12.70×9.53 | 152 |

| 8″x4″ | 200×100 | 219.1×114.3 | 3.76×3.05 | 8.18×6.02 | 12.70×8.56 | 152 |

| 8″x3″ | 200×80 | 219.3×88.9 | 3.76×3.05 | 8.18×5.49 | 12.70×7.62 | 152 |

| 10″x8″ | 250×200 | 273.0×219.1 | 4.19×3.76 | 9.27×8.18 | 15.09×12.70 | 178 |

| 10″x6″ | 250×150 | 273.0×168.3 | 4.19×3.40 | 9.27×7.11 | 15.09×10.97 | 178 |

| 10″x5″ | 250×125 | 273.0×141.3 | 4.19×3.40 | 9.27×6.55 | 15.09×9.53 | 178 |

| 10″x4″ | 250×100 | 273.0×114.3 | 4.19×3.05 | 9.27×6.02 | 15.09×8.56 | 178 |

| 12″x10″ | 300×250 | 323.8×273.0 | 4.57×4.19 | 10.31×9.27 | 17.48×15.09 | 203 |

| 12″x8″ | 300×200 | 323.8×219.1 | 4.57×3.76 | 10.31×8.18 | 17.48×12.70 | 203 |

| 12″x6″ | 300×150 | 323.8×168.3 | 4.57×3.40 | 10.31×7.11 | 17.48×10.97 | 203 |

| 12″x5″ | 300×125 | 323.8×141.3 | 4.57×3.40 | 10.31×6.55 | 17.48×9.53 | 203 |

| 12″x4″ | 300×100 | 323.8×114.3 | 4.57×3.05 | 10.31×6.02 | 17.48×8.56 | 203 |

| 14″x12″ | 350×300 | 355.6×323.8 | 6.35×4.57 | 11.13×10.31 | 19.05×17.48 | 330 |

| 14″x10″ | 350×250 | 355.6×273.0 | 6.35×4.19 | 11.13×9.27 | 19.05×15.09 | 330 |

| 14″x8″ | 350×200 | 355.6×219.1 | 6.35×3.76 | 11.13×8.18 | 19.05×12.70 | 330 |

| 14″x6″ | 350×150 | 355.6×168.3 | 6.35×3.40 | 11.13×7.11 | 19.05×10.97 | 330 |

| 16″x14″ | 400×350 | 406.4×355.6 | 6.35×6.35 | 12.70×11.13 | 21.44×19.05 | 356 |

| 16″x12″ | 400×300 | 406.4×323.8 | 6.35×4.57 | 12.70×10.31 | 21.44×17.48 | 356 |

| 16″x10″ | 400×250 | 406.4×273.0 | 6.35×4.19 | 12.70×9.27 | 21.44×15.09 | 356 |

| 16″x8″ | 400×200 | 406.4×219.1 | 6.35×3.76 | 12.70×8.18 | 21.44×12.70 | 356 |

| 16″x6″ | 400×150 | 406.4×168.3 | 6.35×3.40 | 12.70×7.11 | 21.44×10.97 | 356 |

| 18″x16″ | 450×400 | 457×406.4 | 6.35×6.35 | 14.27x 12.70 | 23.83×21.44 | 381 |

| 18″x14″ | 450×350 | 457x 355.6 | 6.35×6.35 | 14.27×11.13 | 23.83×19.05 | 381 |

| 18″x12″ | 450×300 | 457×323.8 | 6.35×4.57 | 14.27x 10.31 | 23.83×17.48 | 381 |

| 18″x10″ | 450×250 | 457×273.0 | 6.35×4.19 | 14.27×9.27 | 23.83×15.09 | 381 |

| 18″x8″ | 450×200 | 457×219.1 | 6.35×3.76 | 14.27×8.18 | 23.83×12.70 | 381 |

| 20″x18″ | 500×450 | 508×457 | 6.35×6.35 | 15.09×14.27 | 26.19×23.83 | 508 |

| 20″x16″ | 500×400 | 508×406.4 | 6.35×6.35 | 15.09×12.70 | 26.19×21.44 | 508 |

| 20″x14″ | 500×350 | 508×355.6 | 6.35×6.35 | 15.09×11.13 | 26.19×19.05 | 508 |

| 20″x12″ | 500×300 | 508×323.8 | 6.35×4.57 | 15.09×10.31 | 26.19×17.48 | 508 |

| 20″x10″ | 500×250 | 508×273.0 | 6.35×4.19 | 15.09×9.27 | 26.19×15.09 | 508 |

| 20″x8″ | 500×200 | 508×219.1 | 6.35×3.76 | 15.09×8.18 | 26.19×12.70 | 508 |

| 24″x20″ | 600×500 | 610×508 | 6.35×6.35 | 17.48×15.09 | 30.96×26.19 | 508 |

| 24″x18″ | 600×450 | 610×457 | 6.35×6.35 | 17.48×14.27 | 30.96×23.83 | 508 |

| 24″x16″ | 600×400 | 610×406.4 | 6.35×6.35 | 17.48×12.70 | 30.96×21.44 | 508 |

| 24″x14″ | 600×350 | 610×355.6 | 6.35×6.35 | 17.48×11.13 | 30.96×19.05 | 508 |

| 24″x12″ | 600×300 | 610×323.8 | 6.35×4.57 | 17.48×10.31 | 30.96×17.48 | 508 |

| 24″x10″ | 600×250 | 610×273.0 | 6.35×4.19 | 17.48×9.27 | 30.96×15.09 | 508 |

Note: The thickness is available with Sch5, Sch10, Sch30, Sch40, Sch80, Sch120, Sch160, STD, XS, XXS, 5S, 10S, 40S, 80S, etc.

application

- Special pipeline layout: Used for connecting pipes of different diameters with offset axes, addressing space constraints or pipeline avoidance requirements (e.g., bypassing beams, columns, or equipment).

- Anti-liquid accumulation design: Features a single-sided horizontal transition to prevent liquid from accumulating at the bottom of the pipeline, suitable for applications such as pump inlets and horizontal process pipelines where anti-clogging is required.

- Key industries: Chemical processes, oil and gas transportation, and water treatment systems where both diameter changes and drainage functions are required.

advantages

- Flexibility in space: Special structure realizes non-coaxial diameter changes, solves installation space conflict. Straight pipe bottom allows easy cleaning and drainage of liquids (no liquid pockets).

- Improvement fluid efficiency3) Conical design low turbulence (less pressure loss), highly appropriate for solid content/viscous media.

- Structural Reliability: Seamless pipes equal to pressurization can withstand higher & higher pressure & work, and it changes over time. Ensures zero-leakage sealing in the long run at welded joints.

- Material Versatility: American system carbon steel ASTM A234, an economic type of materials for the conventional industrial pipe line. 304 or 316L stainless steel to satisfy amphistaic corrosion-resistance and food, pharmaceutical and hygiene standard .

packing

- Precision Protection Plan:

- Surface Treatment: Rust prevention, hot-dip galvanizing (outdoor/high-humidity environment), acid washing and passivation (stainless steel corrosion prevention)

- Single-Sided Foam: Wrap custom foam in eccentric areas to prevent deformation due to transport impact.

- Tiered Packaging Strategy:

- Small Diameter (≤6″): Conductors bundled with caps on ends

- Large Diameter (>6″): One-piece wooden box + internal steel frame fixation, center of gravity to be taken seriously.

- Smart Identification System:

- Installation direction was clearly same with Arrows + text arrows (top flat / bottom flat).

- Printing of outer box specification (for example, DN200→DN150 bottom flat), material code and anti-tip mark

Available size

| Size(DXD₁) | Thickness TXT₁ (mm) | H (mm) | ||||

| NPS | DN | OD(mm) | Sch10 | Sch40 | Sch80 | |

| 3/4″x1/2″ | 20×15 | 26.7×21.3 | 2.11×2.11 | 2.87×2.77 | 3.91×3.73 | 38 |

| 1″x3/4″ | 25×20 | 33.4×26.7 | 2.77×2.11 | 3.38×2.87 | 4.55×3.91 | 51 |

| 1″x1/2″ | 25×15 | 33.4×21.3 | 2.77×2.11 | 3.38×2.77 | 4.55×3.73 | 51 |

| 1-1/4″x1″ | 32×25 | 42.2×33.4 | 2.77×2.77 | 3.56×3.38 | 4.85×4.55 | 51 |

| 1-1/4″x 3/4″ | 32x 20 | 42.2×26.7 | 2.77×2.11 | 3.56×2.87 | 4.85×3.91 | 51 |

| 1-1/4″x1/2″ | 32x 15 | 42.2×21.3 | 2.77×2.11 | 3.56×2.77 | 4.85×3.73 | 51 |

| 1-1/2″x1-1/4″ | 40×32 | 48.3×42.2 | 2.77×2.77 | 3.68×3.56 | 5.08×4.85 | 64 |

| 1-1/2″x1″ | 40×25 | 48.3×33.4 | 2.77×2.77 | 3.68x 3.38 | 5.08×4.55 | 64 |

| 1-1/2″x 3/4″ | 40×20 | 48.3×26.7 | 2.77×2.11 | 3.68×2.87 | 5.08×3.91 | 64 |

| 1-1/2″x1/2″ | 40×15 | 48.3×21.3 | 2.77×2.11 | 3.68×2.77 | 5.08×3.73 | 64 |

| 2″x1-1/2″ | 50×40 | 60.3×48.3 | 2.77×2.77 | 3.91×3.68 | 5.54×5.08 | 76 |

| 2″x1-1/4″ | 50×32 | 60.3×42.2 | 2.77×2.77 | 3.91×3.56 | 5.54×4.85 | 76 |

| 2″x1″ | 50×25 | 60.3×33.4 | 2.77×2.77 | 3.91x 3.38 | 5.54×4.55 | 76 |

| 2″x3/4″ | 50x 20 | 60.3×26.7 | 2.77×2.11 | 3.91×2.87 | 5.54×3.91 | 76 |

| 2″x1/2″ | 65×50 | 60.3×21.3 | 2.77×2.11 | 3.91×2.77 | 5.54×3.73 | 89 |

| 2-1/2″x2″ | 65×50 | 73.0×60.3 | 3.05×2.77 | 5.16×3.91 | 7.01×5.54 | 89 |

| 2-1/2″x1-1/2″ | 65×40 | 73.0×48.3 | 3.05×2.77 | 5.16×3.68 | 7.01×5.08 | 89 |

| 2-1/2″x1-1/4″ | 65×32 | 73.0×42.2 | 3.05×2.77 | 5.16×3.56 | 7.01×4.85 | 89 |

| 2-1/2″x1″ | 65xx25 | 73.0×33.4 | 3.05×2.77 | 5.16×3.38 | 7.01×4.55 | 89 |

| 2-1/2″x3/4″ | 65×20 | 73.0×26.7 | 3.05×2.11 | 5.16×2.87 | 7.01×3.91 | 89 |

| 3″x2-1/2″ | 80×65 | 88.9×73.0 | 3.05×3.05 | 5.49×5.16 | 7.62×7.01 | 89 |

| 3″x2″ | 80×50 | 88.9×60.3 | 3.05×2.77 | 5.49×3.91 | 7.62×5.54 | 89 |

| 3″x1-1/2″ | 80xx40 | 88.9×48.3 | 3.05×2.77 | 5.49×3.68 | 7.62×5.08 | 89 |

| 3″x1-1/4″ | 80×32 | 88.9×42.2 | 3.05×2.77 | 5.49×3.56 | 7.62×4.85 | 89 |

| 3″x1″ | 80×25 | 88.9×33.4 | 3.05×2.77 | 5.49×3.38 | 7.62×4.55 | 89 |

| 4″x3″ | 100×80 | 114.3×88.9 | 3.05×3.05 | 6.02×5.49 | 8.56×7.62 | 102 |

| 4″x2-1/2″ | 100×65 | 114.3×73.0 | 3.05×3.05 | 6.02×5.16 | 8.56×7.01 | 102 |

| 4″x2″ | 100×50 | 114.3×60.3 | 3.05×2.77 | 6.02×3.91 | 8.56×5.54 | 102 |

| 4″x1-1/2″ | 100×40 | 114.3×48.3 | 3.05×2.77 | 6.02×3.68 | 8.56×5.08 | 102 |

| 4″x1-1/4″ | 100×32 | 114.3×42.2 | 3.05×2.77 | 6.02×3.56 | 8.56×4.85 | 102 |

| 4″x1″ | 100×25 | 114.3×33.4 | 3.05×2.77 | 6.02×3.38 | 8.56×4.55 | 102 |

| 5″x4″ | 125×100 | 141.3×114.3 | 3.40×3.05 | 6.55×6.02 | 9.53×8.56 | 127 |

| 5″x3″ | 125×80 | 141.3×88.9 | 3.40×3.05 | 6.55×5.49 | 9.53×7.62 | 127 |

| 5″x2-1/2″ | 125×65 | 141.3×73.0 | 3.40×3.05 | 6.55×5.16 | 9.53×7.01 | 127 |

| 5″x2″ | 125×50 | 141.3×60.3 | 3.40×2.77 | 6.55×3.91 | 9.53×5.54 | 127 |

| 6″x5″ | 150×125 | 168.3×141.3 | 3.40×3.40 | 7.11×6.55 | 10.97×9.53 | 140 |

| 6″x4″ | 150×100 | 168.3×114.3 | 3.40×3.05 | 7.11×6.02 | 10.97×8.56 | 140 |

| 6″x3″ | 150×80 | 168.3×88.9 | 3.40×3.05 | 7.11×5.49 | 10.97×7.62 | 140 |

| 6″x2-1/2″ | 150×65 | 168.3×73.0 | 3.40×3.05 | 7.11×5.16 | 10.97×7.01 | 140 |

| 6″x2″ | 150×50 | 168.3×60.3 | 3.40×2.77 | 7.11×3.91 | 10.97×5.54 | 140 |

| 8″x6″ | 200×150 | 219.1×168.3 | 3.76×3.40 | 8.18×7.11 | 12.70×10.97 | 152 |

| 8″x5″ | 200×125 | 219.1×141.3 | 3.76×3.40 | 8.18×6.55 | 12.70×9.53 | 152 |

| 8″x4″ | 200×100 | 219.1×114.3 | 3.76×3.05 | 8.18×6.02 | 12.70×8.56 | 152 |

| 8″x3″ | 200×80 | 219.3×88.9 | 3.76×3.05 | 8.18×5.49 | 12.70×7.62 | 152 |

| 10″x8″ | 250×200 | 273.0×219.1 | 4.19×3.76 | 9.27×8.18 | 15.09×12.70 | 178 |

| 10″x6″ | 250×150 | 273.0×168.3 | 4.19×3.40 | 9.27×7.11 | 15.09×10.97 | 178 |

| 10″x5″ | 250×125 | 273.0×141.3 | 4.19×3.40 | 9.27×6.55 | 15.09×9.53 | 178 |

| 10″x4″ | 250×100 | 273.0×114.3 | 4.19×3.05 | 9.27×6.02 | 15.09×8.56 | 178 |

| 12″x10″ | 300×250 | 323.8×273.0 | 4.57×4.19 | 10.31×9.27 | 17.48×15.09 | 203 |

| 12″x8″ | 300×200 | 323.8×219.1 | 4.57×3.76 | 10.31×8.18 | 17.48×12.70 | 203 |

| 12″x6″ | 300×150 | 323.8×168.3 | 4.57×3.40 | 10.31×7.11 | 17.48×10.97 | 203 |

| 12″x5″ | 300×125 | 323.8×141.3 | 4.57×3.40 | 10.31×6.55 | 17.48×9.53 | 203 |

| 12″x4″ | 300×100 | 323.8×114.3 | 4.57×3.05 | 10.31×6.02 | 17.48×8.56 | 203 |

| 14″x12″ | 350×300 | 355.6×323.8 | 6.35×4.57 | 11.13×10.31 | 19.05×17.48 | 330 |

| 14″x10″ | 350×250 | 355.6×273.0 | 6.35×4.19 | 11.13×9.27 | 19.05×15.09 | 330 |

| 14″x8″ | 350×200 | 355.6×219.1 | 6.35×3.76 | 11.13×8.18 | 19.05×12.70 | 330 |

| 14″x6″ | 350×150 | 355.6×168.3 | 6.35×3.40 | 11.13×7.11 | 19.05×10.97 | 330 |

| 16″x14″ | 400×350 | 406.4×355.6 | 6.35×6.35 | 12.70×11.13 | 21.44×19.05 | 356 |

| 16″x12″ | 400×300 | 406.4×323.8 | 6.35×4.57 | 12.70×10.31 | 21.44×17.48 | 356 |

| 16″x10″ | 400×250 | 406.4×273.0 | 6.35×4.19 | 12.70×9.27 | 21.44×15.09 | 356 |

| 16″x8″ | 400×200 | 406.4×219.1 | 6.35×3.76 | 12.70×8.18 | 21.44×12.70 | 356 |

| 16″x6″ | 400×150 | 406.4×168.3 | 6.35×3.40 | 12.70×7.11 | 21.44×10.97 | 356 |

| 18″x16″ | 450×400 | 457×406.4 | 6.35×6.35 | 14.27x 12.70 | 23.83×21.44 | 381 |

| 18″x14″ | 450×350 | 457x 355.6 | 6.35×6.35 | 14.27×11.13 | 23.83×19.05 | 381 |

| 18″x12″ | 450×300 | 457×323.8 | 6.35×4.57 | 14.27x 10.31 | 23.83×17.48 | 381 |

| 18″x10″ | 450×250 | 457×273.0 | 6.35×4.19 | 14.27×9.27 | 23.83×15.09 | 381 |

| 18″x8″ | 450×200 | 457×219.1 | 6.35×3.76 | 14.27×8.18 | 23.83×12.70 | 381 |

| 20″x18″ | 500×450 | 508×457 | 6.35×6.35 | 15.09×14.27 | 26.19×23.83 | 508 |

| 20″x16″ | 500×400 | 508×406.4 | 6.35×6.35 | 15.09×12.70 | 26.19×21.44 | 508 |

| 20″x14″ | 500×350 | 508×355.6 | 6.35×6.35 | 15.09×11.13 | 26.19×19.05 | 508 |

| 20″x12″ | 500×300 | 508×323.8 | 6.35×4.57 | 15.09×10.31 | 26.19×17.48 | 508 |

| 20″x10″ | 500×250 | 508×273.0 | 6.35×4.19 | 15.09×9.27 | 26.19×15.09 | 508 |

| 20″x8″ | 500×200 | 508×219.1 | 6.35×3.76 | 15.09×8.18 | 26.19×12.70 | 508 |

| 24″x20″ | 600×500 | 610×508 | 6.35×6.35 | 17.48×15.09 | 30.96×26.19 | 508 |

| 24″x18″ | 600×450 | 610×457 | 6.35×6.35 | 17.48×14.27 | 30.96×23.83 | 508 |

| 24″x16″ | 600×400 | 610×406.4 | 6.35×6.35 | 17.48×12.70 | 30.96×21.44 | 508 |

| 24″x14″ | 600×350 | 610×355.6 | 6.35×6.35 | 17.48×11.13 | 30.96×19.05 | 508 |

| 24″x12″ | 600×300 | 610×323.8 | 6.35×4.57 | 17.48×10.31 | 30.96×17.48 | 508 |

| 24″x10″ | 600×250 | 610×273.0 | 6.35×4.19 | 17.48×9.27 | 30.96×15.09 | 508 |

Note: The thickness is available with Sch5, Sch10, Sch30, Sch40, Sch80, Sch120, Sch160, STD, XS, XXS, 5S, 10S, 40S, 80S, etc.

- Special pipeline layout: Used for connecting pipes of different diameters with offset axes, addressing space constraints or pipeline avoidance requirements (e.g., bypassing beams, columns, or equipment).

- Anti-liquid accumulation design: Features a single-sided horizontal transition to prevent liquid from accumulating at the bottom of the pipeline, suitable for applications such as pump inlets and horizontal process pipelines where anti-clogging is required.

- Key industries: Chemical processes, oil and gas transportation, and water treatment systems where both diameter changes and drainage functions are required.

- Flexibility in space: Special structure realizes non-coaxial diameter changes, solves installation space conflict. Straight pipe bottom allows easy cleaning and drainage of liquids (no liquid pockets).

- Improvement fluid efficiency3) Conical design low turbulence (less pressure loss), highly appropriate for solid content/viscous media.

- Structural Reliability: Seamless pipes equal to pressurization can withstand higher & higher pressure & work, and it changes over time. Ensures zero-leakage sealing in the long run at welded joints.

- Material Versatility: American system carbon steel ASTM A234, an economic type of materials for the conventional industrial pipe line. 304 or 316L stainless steel to satisfy amphistaic corrosion-resistance and food, pharmaceutical and hygiene standard .

- Precision Protection Plan:

- Surface Treatment: Rust prevention, hot-dip galvanizing (outdoor/high-humidity environment), acid washing and passivation (stainless steel corrosion prevention)

- Single-Sided Foam: Wrap custom foam in eccentric areas to prevent deformation due to transport impact.

- Tiered Packaging Strategy:

- Small Diameter (≤6″): Conductors bundled with caps on ends

- Large Diameter (>6″): One-piece wooden box + internal steel frame fixation, center of gravity to be taken seriously.

- Smart Identification System:

- Installation direction was clearly same with Arrows + text arrows (top flat / bottom flat).

- Printing of outer box specification (for example, DN200→DN150 bottom flat), material code and anti-tip mark

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.