HOT PRODUCTS TAGS

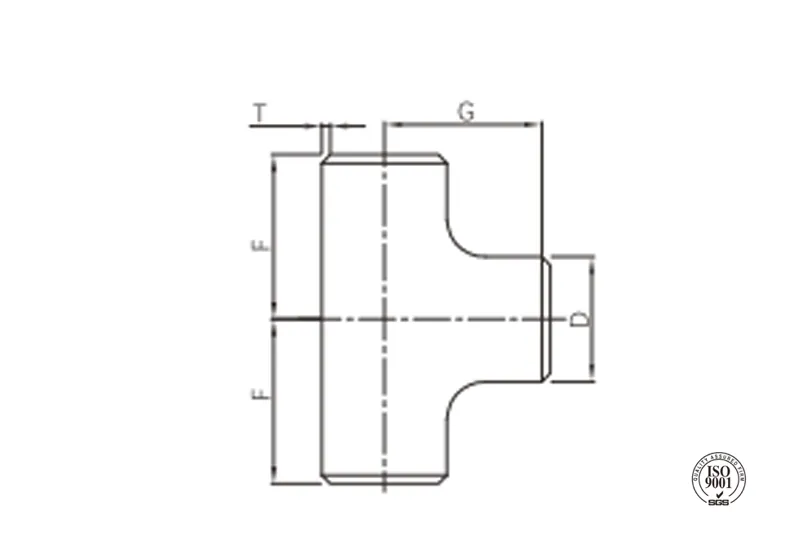

Butt weld equal tee

·Standard: ISO

EN 10253-1 / EN 10253-2 / EN 10253-3

·Material: Carbon steel S235 / P235TR2

SS equivalent to WP304 / WP316L

·W. pressure: Equal to same straight pipe

·Surface: Black painting / hot dip galvanized

Pickling white, etc.

·Size range: 1″-24″

description

butt weld equal tee, T-shaped, through equal diameter design and welding connection to achieve low resistance fluid smooth diversion, ensure high sealing and structural strength, significantly reduce energy consumption and maintenance costs.

Specification

Available size

| Size | Preferred T to EN 10253-2(mm) | F(mm) | G(mm) | ||

| NPS | DN | OD(mm) | |||

| 1/2″ | 15 | 21.3 | 2.0/2.6/3.214.0/5.017.1 | 25 | 25 |

| 3/4″ | 20 | 26.9 | 2.3/2.6/3.214.014.5/5.6/8.0 | 29 | 29 |

| 1″ | 25 | 33.7 | 2.6/3.214.0/4.5/5.6/6.3/8.8 | 38 | 38 |

| 1-1/4″ | 32 | 42.4 | 2.6/3.6/4.015.0/6.3/8.0/10.0 | 48 | 48 |

| 1-1/2″ | 40 | 48.3 | 2.6/3.6/4.0/5.0/6.3/8.0/10.0 | 57 | 57 |

| 2″ | 50 | 60.3 | 2.9/3.6/4.0/5.6/7.1/8.8/11.0 | 64 | 64 |

| 2-1/2″ | 65 | 76.1 | 2.9/3.6/5.6/7.1/8.0/10.0/14.2 | 76 | 76 |

| 3″ | 80 | 88.9 | 3.214.0/5.6/8.0/8.8/11.0/16.0 | 86 | 86 |

| 4″ | 100 | 114.3 | 3.6/4.5/6.3/8.8/11.0/14.2/17.5 | 105 | 105 |

| 5″ | 125 | 139.7 | 4.0/5.0/6.3/10.0/12.5/16.0/20.0 | 124 | 124 |

| 6″ | 150 | 165.1/168.3 | 4.014.515.617.1/11.0/14.2/17.5/22.2 | 143 | 143 |

| 8″ | 200 | 219.1 | 4.5/6.317.1/8.0/12.5/16.0/17.5/22.2 | 178 | 178 |

| 10″ | 250 | 273.0 | 5.0/6.3/8.8/10.0/12.5/16.0/22.2/30.0 | 216 | 216 |

| 12″ | 300 | 323.9 | 5.6/7.1/8.8/10.0/12.5/17.5/25.0/32.0 | 254 | 254 |

| 14″ | 350 | 355.6 | 5.6/8.0/10.0/12.5/16.0/20.0/28.0/36.0 | 279 | 279 |

| 16″ | 400 | 406.4 | 6.3/8.8110.0/12.5/17.5/22.2/30.0/40.0 | 305 | 305 |

| 18″ | 450 | 457 | 6.3/10.0/11.0/12.5117.5/22.2/32.0/45.0 | 343 | 343 |

| 20″ | 500 | 508 | 6.3/10.0/11.0/12.5/17.5/25.0/36.0/50.0 | 381 | 381 |

| 24″ | 600 | 610 | 6.3/10.0/12.5/17.5/25.0/30.0/45.0/60.0 | 432 | 432 |

application

- Used for T-type diversion in pipeline systems, it achieves equal-diameter three-way fluid distribution and ensures balanced flow in each branch.

- It is suitable for critical diversion/convergence nodes, such as chemical production line branches, fire protection pipe networks, energy transmission trunk lines, and industrial equipment multi-channel interfaces.

- It is indispensable in systems that require equal-section diversion and stable pressure.

advantages

- A zero-loss design of fluid: An equal-diameter structure (the diameter of the main pipe and the diameter of the branch pipe are the same), to prevent a sudden change in cross-section, can reduce turbulence and pressure loss.

- High sealing integration: All butt welding overall, specifically to achieve a three-way zero leakage interface and the same specification of straight pipe pressure-bearing capacity.

- Multi-material: Standard carbon steel, stainless steel or specified other materials (WP304/WP316L equivalent)Material version that can be used for corrosive media and high-purity systems

- Innovative assembly facilitation: Single component replaces welded groups, by 70% reduction of welds for better manufacturing efficiency and robustness.

- Surface strengthening: optional black painting; hot-dip galvanizing (thick protective layer, strong corrosion resistance); acid polishing and passivation of the surface (suitable for stainless steel).

- Large-range coverage: full series specifications from 1 inch to 24 inches (NPS), applicable to both micro-pipes and main pipelines.

packing

- Three-dimensional protective packaging: Customized wooden boxes + internal foam molding are used to precisely fit the tee structure and prevent transportation collisions.

- Triple port protection: Silicone seals are added to the three-way pipe openings, and the outer layer is covered with scratch-resistant PE film.

- Anti-Corrosion Technology: Carbon steel components are fully wrapped in vapor-phase corrosion inhibitor (VCI) paper, while stainless steel components are coated with an anti-fingerprint finish.

- Smart Labeling System: The box is labeled with the product name, “equal-diameter three-way fitting” identifier, dimensions, and “↑Up↑” stacking instructions.

Available size

| Size | Preferred T to EN 10253-2(mm) | F(mm) | G(mm) | ||

| NPS | DN | OD(mm) | |||

| 1/2″ | 15 | 21.3 | 2.0/2.6/3.214.0/5.017.1 | 25 | 25 |

| 3/4″ | 20 | 26.9 | 2.3/2.6/3.214.014.5/5.6/8.0 | 29 | 29 |

| 1″ | 25 | 33.7 | 2.6/3.214.0/4.5/5.6/6.3/8.8 | 38 | 38 |

| 1-1/4″ | 32 | 42.4 | 2.6/3.6/4.015.0/6.3/8.0/10.0 | 48 | 48 |

| 1-1/2″ | 40 | 48.3 | 2.6/3.6/4.0/5.0/6.3/8.0/10.0 | 57 | 57 |

| 2″ | 50 | 60.3 | 2.9/3.6/4.0/5.6/7.1/8.8/11.0 | 64 | 64 |

| 2-1/2″ | 65 | 76.1 | 2.9/3.6/5.6/7.1/8.0/10.0/14.2 | 76 | 76 |

| 3″ | 80 | 88.9 | 3.214.0/5.6/8.0/8.8/11.0/16.0 | 86 | 86 |

| 4″ | 100 | 114.3 | 3.6/4.5/6.3/8.8/11.0/14.2/17.5 | 105 | 105 |

| 5″ | 125 | 139.7 | 4.0/5.0/6.3/10.0/12.5/16.0/20.0 | 124 | 124 |

| 6″ | 150 | 165.1/168.3 | 4.014.515.617.1/11.0/14.2/17.5/22.2 | 143 | 143 |

| 8″ | 200 | 219.1 | 4.5/6.317.1/8.0/12.5/16.0/17.5/22.2 | 178 | 178 |

| 10″ | 250 | 273.0 | 5.0/6.3/8.8/10.0/12.5/16.0/22.2/30.0 | 216 | 216 |

| 12″ | 300 | 323.9 | 5.6/7.1/8.8/10.0/12.5/17.5/25.0/32.0 | 254 | 254 |

| 14″ | 350 | 355.6 | 5.6/8.0/10.0/12.5/16.0/20.0/28.0/36.0 | 279 | 279 |

| 16″ | 400 | 406.4 | 6.3/8.8110.0/12.5/17.5/22.2/30.0/40.0 | 305 | 305 |

| 18″ | 450 | 457 | 6.3/10.0/11.0/12.5117.5/22.2/32.0/45.0 | 343 | 343 |

| 20″ | 500 | 508 | 6.3/10.0/11.0/12.5/17.5/25.0/36.0/50.0 | 381 | 381 |

| 24″ | 600 | 610 | 6.3/10.0/12.5/17.5/25.0/30.0/45.0/60.0 | 432 | 432 |

- Used for T-type diversion in pipeline systems, it achieves equal-diameter three-way fluid distribution and ensures balanced flow in each branch.

- It is suitable for critical diversion/convergence nodes, such as chemical production line branches, fire protection pipe networks, energy transmission trunk lines, and industrial equipment multi-channel interfaces.

- It is indispensable in systems that require equal-section diversion and stable pressure.

- A zero-loss design of fluid: An equal-diameter structure (the diameter of the main pipe and the diameter of the branch pipe are the same), to prevent a sudden change in cross-section, can reduce turbulence and pressure loss.

- High sealing integration: All butt welding overall, specifically to achieve a three-way zero leakage interface and the same specification of straight pipe pressure-bearing capacity.

- Multi-material: Standard carbon steel, stainless steel or specified other materials (WP304/WP316L equivalent)Material version that can be used for corrosive media and high-purity systems

- Innovative assembly facilitation: Single component replaces welded groups, by 70% reduction of welds for better manufacturing efficiency and robustness.

- Surface strengthening: optional black painting; hot-dip galvanizing (thick protective layer, strong corrosion resistance); acid polishing and passivation of the surface (suitable for stainless steel).

- Large-range coverage: full series specifications from 1 inch to 24 inches (NPS), applicable to both micro-pipes and main pipelines.

- Three-dimensional protective packaging: Customized wooden boxes + internal foam molding are used to precisely fit the tee structure and prevent transportation collisions.

- Triple port protection: Silicone seals are added to the three-way pipe openings, and the outer layer is covered with scratch-resistant PE film.

- Anti-Corrosion Technology: Carbon steel components are fully wrapped in vapor-phase corrosion inhibitor (VCI) paper, while stainless steel components are coated with an anti-fingerprint finish.

- Smart Labeling System: The box is labeled with the product name, “equal-diameter three-way fitting” identifier, dimensions, and “↑Up↑” stacking instructions.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.