HOT PRODUCTS TAGS

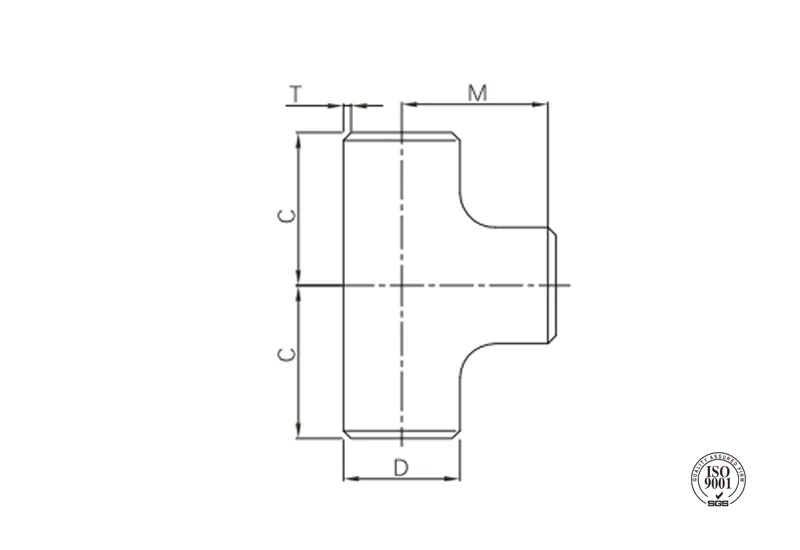

Butt weld straight tee (Equal tee)

·Standard: ISO

ASME B16.9

·Material: Carbon steel ASTM A234, WPB

SS ASTM A403, WP304 / WP316L

·W. pressure: Equal to same seamless pipe

·Surface: Black painting / hot dip galvanized Pickling white, etc.

·Size range: 1″-24″

description

butt weld straight tee (equal tee) is T-shaped and is used to create branch pipes in the 90-degree direction, ensuring high-pressure sealing while optimizing fluid distribution efficiency.

Specification

Available size

| Size | Thickness(mm) | C(mm) | M(mm) | ||||

| NPS | DN | OD(mm) | Sch10 | Sch40 | Sch80 | ||

| 1/2″ | 15 | 21.3 | 2.11 | 2.77 | 3.73 | 25 | 25 |

| 3/4″ | 20 | 26.7 | 2.11 | 2.87 | 3.91 | 29 | 29 |

| 1″ | 25 | 33.4 | 2.77 | 3.38 | 4.55 | 38 | 38 |

| 1-1/4″ | 32 | 42.2 | 2.77 | 3.56 | 4.85 | 48 | 48 |

| 1-1/2″ | 40 | 48.3 | 2.77 | 3.68 | 5.08 | 57 | 57 |

| 2″ | 50 | 60.3 | 2.77 | 3.91 | 5.54 | 64 | 64 |

| 2-1/2″ | 65 | 73.0 | 3.05 | 5.16 | 7.01 | 76 | 76 |

| 3″ | 80 | 88.9 | 3.05 | 5.49 | 7.62 | 86 | 86 |

| 4″ | 100 | 114.3 | 3.05 | 6.02 | 8.56 | 105 | 105 |

| 5″ | 125 | 141.3 | 3.40 | 6.55 | 9.53 | 124 | 124 |

| 6″ | 150 | 168.3 | 3.40 | 7.11 | 10.97 | 143 | 143 |

| 8″ | 200 | 219.1 | 3.76 | 8.18 | 12.70 | 178 | 178 |

| 10″ | 250 | 273.0 | 4.19 | 9.27 | 15.09 | 216 | 216 |

| 12″ | 300 | 323.8 | 4.57 | 10.31 | 17.48 | 254 | 254 |

| 14″ | 350 | 355.6 | 6.35 | 11.13 | 19.05 | 279 | 279 |

| 16″ | 400 | 406.4 | 6.35 | 12.70 | 21.44 | 305 | 305 |

| 18″ | 450 | 457 | 6.35 | 14.27 | 23.83 | 343 | 343 |

| 20″ | 500 | 508 | 6.35 | 15.09 | 26.19 | 381 | 381 |

| 24″ | 600 | 610 | 6.35 | 17.48 | 30.96 | 432 | 432 |

Note: The thickness is available with Sch5, Sch10, Sch30, Sch40, Sch80, Sch120, Sch160, STD, XS, XXS, 5S, 10S, 40S, 80S, etc.

application

- Multi-directional fluid distribution: Specifically designed for pipeline systems requiring 90-degree branching, such as chemical plant reaction unit branches, HVAC distribution lines, and fire protection network branches, to achieve efficient medium distribution.

- Compact space piping: Suitable for equipment-dense areas and narrow pipe gallery sections, with a single component replacing welded assemblies to save installation space.

- Rugged Environment Compatibility: Available in carbon steel or stainless steel versions, suitable for power plant, petrochemical high-temperature/high-pressure pipelines, or food and pharmaceutical cleanroom systems.

- Full Size Range: Supports pipes from ½ inch to 24 inches (DN15-DN600), compatible with small instruments to industrial main pipelines.

advantages

- Zero-loss flow diversion: no pressure drop is generated through the same caliber tees for branches and mainlines, achieving reducing energy waste.

- Strong corrosion resistance: the quality of base material + galvanized or acid-pickling surface treatment, anti-chemical corrosion and rust, lifetime underground engineering more than 20 years.

- Direct sealing: Butt welding connection, the fully welded valve body can make the medium source in direct contact with the seal ring to avoid any leakage of dangerous media.

- Permanently reliable welding: Single-piece welded design with moving parts eliminated, maintenance-free and no risk of loosening.

- Reduction of approx 5.30% in cost: This new fabrication solution replaces traditional welded tee components, eliminating the need for multiple welds and on-site installation labor hours. High-

- pressure and high-temperature: Can be similar to the pipeline, suitable for harsh fluids such as steam and hot oil .

packing

- Three-port reinforced protection:

- Each port is fitted with a plastic cover + rust-proof film wrapping, and the entire unit is placed in a thickened cardboard box (marked: equal-diameter tee, 6 inches).

- Stainless steel products are equipped with an anti-scratch pearl cotton layer.

- Large-size deformation prevention solution:

- For 8 inches and above, a compartmentalized wooden box is used, with the three ports secured by custom foam inserts to prevent transportation collisions.

- Smart nested transportation:

- Small-sized multiple items are nested and packed together, while large-sized items are packed individually in wooden boxes, improving container space utilization by 35%.

Available size

| Size | Thickness(mm) | C(mm) | M(mm) | ||||

| NPS | DN | OD(mm) | Sch10 | Sch40 | Sch80 | ||

| 1/2″ | 15 | 21.3 | 2.11 | 2.77 | 3.73 | 25 | 25 |

| 3/4″ | 20 | 26.7 | 2.11 | 2.87 | 3.91 | 29 | 29 |

| 1″ | 25 | 33.4 | 2.77 | 3.38 | 4.55 | 38 | 38 |

| 1-1/4″ | 32 | 42.2 | 2.77 | 3.56 | 4.85 | 48 | 48 |

| 1-1/2″ | 40 | 48.3 | 2.77 | 3.68 | 5.08 | 57 | 57 |

| 2″ | 50 | 60.3 | 2.77 | 3.91 | 5.54 | 64 | 64 |

| 2-1/2″ | 65 | 73.0 | 3.05 | 5.16 | 7.01 | 76 | 76 |

| 3″ | 80 | 88.9 | 3.05 | 5.49 | 7.62 | 86 | 86 |

| 4″ | 100 | 114.3 | 3.05 | 6.02 | 8.56 | 105 | 105 |

| 5″ | 125 | 141.3 | 3.40 | 6.55 | 9.53 | 124 | 124 |

| 6″ | 150 | 168.3 | 3.40 | 7.11 | 10.97 | 143 | 143 |

| 8″ | 200 | 219.1 | 3.76 | 8.18 | 12.70 | 178 | 178 |

| 10″ | 250 | 273.0 | 4.19 | 9.27 | 15.09 | 216 | 216 |

| 12″ | 300 | 323.8 | 4.57 | 10.31 | 17.48 | 254 | 254 |

| 14″ | 350 | 355.6 | 6.35 | 11.13 | 19.05 | 279 | 279 |

| 16″ | 400 | 406.4 | 6.35 | 12.70 | 21.44 | 305 | 305 |

| 18″ | 450 | 457 | 6.35 | 14.27 | 23.83 | 343 | 343 |

| 20″ | 500 | 508 | 6.35 | 15.09 | 26.19 | 381 | 381 |

| 24″ | 600 | 610 | 6.35 | 17.48 | 30.96 | 432 | 432 |

Note: The thickness is available with Sch5, Sch10, Sch30, Sch40, Sch80, Sch120, Sch160, STD, XS, XXS, 5S, 10S, 40S, 80S, etc.

- Multi-directional fluid distribution: Specifically designed for pipeline systems requiring 90-degree branching, such as chemical plant reaction unit branches, HVAC distribution lines, and fire protection network branches, to achieve efficient medium distribution.

- Compact space piping: Suitable for equipment-dense areas and narrow pipe gallery sections, with a single component replacing welded assemblies to save installation space.

- Rugged Environment Compatibility: Available in carbon steel or stainless steel versions, suitable for power plant, petrochemical high-temperature/high-pressure pipelines, or food and pharmaceutical cleanroom systems.

- Full Size Range: Supports pipes from ½ inch to 24 inches (DN15-DN600), compatible with small instruments to industrial main pipelines.

- Zero-loss flow diversion: no pressure drop is generated through the same caliber tees for branches and mainlines, achieving reducing energy waste.

- Strong corrosion resistance: the quality of base material + galvanized or acid-pickling surface treatment, anti-chemical corrosion and rust, lifetime underground engineering more than 20 years.

- Direct sealing: Butt welding connection, the fully welded valve body can make the medium source in direct contact with the seal ring to avoid any leakage of dangerous media.

- Permanently reliable welding: Single-piece welded design with moving parts eliminated, maintenance-free and no risk of loosening.

- Reduction of approx 5.30% in cost: This new fabrication solution replaces traditional welded tee components, eliminating the need for multiple welds and on-site installation labor hours. High-

- pressure and high-temperature: Can be similar to the pipeline, suitable for harsh fluids such as steam and hot oil .

- Three-port reinforced protection:

- Each port is fitted with a plastic cover + rust-proof film wrapping, and the entire unit is placed in a thickened cardboard box (marked: equal-diameter tee, 6 inches).

- Stainless steel products are equipped with an anti-scratch pearl cotton layer.

- Large-size deformation prevention solution:

- For 8 inches and above, a compartmentalized wooden box is used, with the three ports secured by custom foam inserts to prevent transportation collisions.

- Smart nested transportation:

- Small-sized multiple items are nested and packed together, while large-sized items are packed individually in wooden boxes, improving container space utilization by 35%.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.