HOT PRODUCTS TAGS

Lap joint stub end

·Standard: ISO

ASME B16.9

·Material: SS ASTM A403, WP304 / WP316L

·W. pressure: Equal to same seamless pipe

·Surface: Pickling white, etc.

·Size range: 1″-24″

description

Lap joint stub end, used with lap flanges, offer the advantage of easy disassembly and maintenance while reducing the risk of corrosion by separating flanges in contact with fluids, making them ideal for highly corrosion-resistant piping systems that require frequent inspections or are cost-sensitive.

Specification

Available size

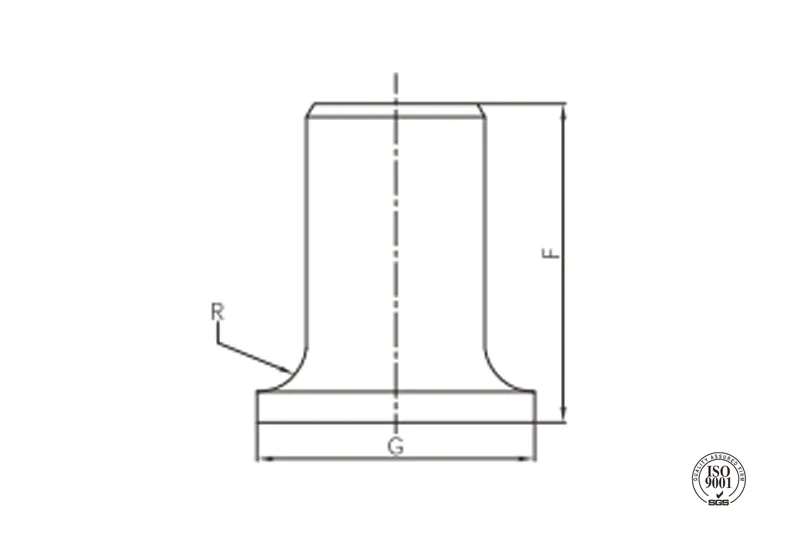

| Size | Length F(mm) | Radius of fillet R(mm) | Lap diameter G(mm) | |||

| NPS | DN | OD(mm) | Long pattern | Short pattern | ||

| 1/2″ | 15 | 21.3 | 76 | 51 | 3 | 35 |

| 3/4″ | 20 | 26.7 | 76 | 51 | 3 | 43 |

| 1″ | 25 | 33.4 | 102 | 51 | 3 | 51 |

| 1-1/4″ | 32 | 42.2 | 102 | 51 | 5 | 64 |

| 1-1/2″ | 40 | 48.3 | 102 | 51 | 6 | 73 |

| 2″ | 50 | 60.3 | 152 | 64 | 8 | 92 |

| 2-1/2″ | 65 | 73.0 | 152 | 64 | 8 | 105 |

| 3″ | 80 | 88.9 | 152 | 64 | 10 | 127 |

| 4″ | 100 | 114.3 | 152 | 76 | 11 | 157 |

| 5” | 125 | 141.3 | 203 | 76 | 11 | 186 |

| 6″ | 150 | 168.3 | 203 | 89 | 13 | 216 |

| 8″ | 200 | 219.1 | 203 | 102 | 13 | 270 |

| 10″ | 250 | 273.0 | 254 | 127 | 13 | 324 |

| 12″ | 300 | 323.8 | 254 | 152 | 13 | 381 |

| 14″ | 350 | 355.6 | 305 | 152 | 13 | 413 |

| 16″ | 400 | 406.4 | 305 | 152 | 13 | 470 |

| 18″ | 450 | 457 | 305 | 152 | 13 | 533 |

| 20″ | 500 | 508 | 305 | 152 | 13 | 584 |

| 24″ | 600 | 610 | 305 | 152 | 13 | 692 |

application

- Removable pipe system: Suitable for flange lap connection, this utilize can be used as piping at the chemical machine cleaning or instrument calibration point where has to be existed and longly chanelled.

- Corrosion-burdened environments: Insulators remove direct media from the end face of the flanges, which is beneficial for highly corrosive media (such as acid wash lines and seawater cooling systems) only at the tip.

- Cost-optimisation scenarios: makes it possible to combine a carbon steel flange with a short-length piece of stainless steel, providing corrosion resistance while reducing costs as a whole .

advantages

- Easy Maintenance: Loosening only the bolts while disassemble, leaving the short section with quick connect ends welded to pipeline, saving times for cutting and welding repeatedly. The reusable flanges reduce spare parts inventory and replacement costs.

- Corrosion-resistant isolation design: The short section is made of stainless steel (304/316L) which comes in direct contact with the medium to prevent the flange from corrosion and prolong system life. Acid Washing (Pickling White) on the surface (ware parts are Acid Washed to make it Stainless Steel best corrosion-resistant.)

- Across-the-board compatibility: ISO/ASME B16. 9 standards, compatible with the global mainstream loose flanges. Long pattern (Long Pattern) / short pattern (Short Pattern), to match up with different installation space.

packing

- Precision Protection Plan:

- Acid-washed surfaces covered with anti-rust paper and bubble wrap to prevent transportation scratches and chloride ion corrosion.

- Custom foam channels with flanged curved surfaces for secure fixation, preventing structural deformation.

- Classified Packaging Strategy:

- Small sizes (≤6″): Grouped by specifications, separated by cardboard partitions before packing.

- Large sizes (>6″): Individually packaged in wooden boxes with built-in anti-vibration brackets.

- Error-proofing Identification System:

- Labels clearly marked with “Requires matching loose flange” and material code (e.g., “316L Stub End”).

- Outer boxes printed with flow direction arrows (to ensure correct flanged direction).

Available size

| Size | Length F(mm) | Radius of fillet R(mm) | Lap diameter G(mm) | |||

| NPS | DN | OD(mm) | Long pattern | Short pattern | ||

| 1/2″ | 15 | 21.3 | 76 | 51 | 3 | 35 |

| 3/4″ | 20 | 26.7 | 76 | 51 | 3 | 43 |

| 1″ | 25 | 33.4 | 102 | 51 | 3 | 51 |

| 1-1/4″ | 32 | 42.2 | 102 | 51 | 5 | 64 |

| 1-1/2″ | 40 | 48.3 | 102 | 51 | 6 | 73 |

| 2″ | 50 | 60.3 | 152 | 64 | 8 | 92 |

| 2-1/2″ | 65 | 73.0 | 152 | 64 | 8 | 105 |

| 3″ | 80 | 88.9 | 152 | 64 | 10 | 127 |

| 4″ | 100 | 114.3 | 152 | 76 | 11 | 157 |

| 5” | 125 | 141.3 | 203 | 76 | 11 | 186 |

| 6″ | 150 | 168.3 | 203 | 89 | 13 | 216 |

| 8″ | 200 | 219.1 | 203 | 102 | 13 | 270 |

| 10″ | 250 | 273.0 | 254 | 127 | 13 | 324 |

| 12″ | 300 | 323.8 | 254 | 152 | 13 | 381 |

| 14″ | 350 | 355.6 | 305 | 152 | 13 | 413 |

| 16″ | 400 | 406.4 | 305 | 152 | 13 | 470 |

| 18″ | 450 | 457 | 305 | 152 | 13 | 533 |

| 20″ | 500 | 508 | 305 | 152 | 13 | 584 |

| 24″ | 600 | 610 | 305 | 152 | 13 | 692 |

- Removable pipe system: Suitable for flange lap connection, this utilize can be used as piping at the chemical machine cleaning or instrument calibration point where has to be existed and longly chanelled.

- Corrosion-burdened environments: Insulators remove direct media from the end face of the flanges, which is beneficial for highly corrosive media (such as acid wash lines and seawater cooling systems) only at the tip.

- Cost-optimisation scenarios: makes it possible to combine a carbon steel flange with a short-length piece of stainless steel, providing corrosion resistance while reducing costs as a whole .

- Easy Maintenance: Loosening only the bolts while disassemble, leaving the short section with quick connect ends welded to pipeline, saving times for cutting and welding repeatedly. The reusable flanges reduce spare parts inventory and replacement costs.

- Corrosion-resistant isolation design: The short section is made of stainless steel (304/316L) which comes in direct contact with the medium to prevent the flange from corrosion and prolong system life. Acid Washing (Pickling White) on the surface (ware parts are Acid Washed to make it Stainless Steel best corrosion-resistant.)

- Across-the-board compatibility: ISO/ASME B16. 9 standards, compatible with the global mainstream loose flanges. Long pattern (Long Pattern) / short pattern (Short Pattern), to match up with different installation space.

- Precision Protection Plan:

- Acid-washed surfaces covered with anti-rust paper and bubble wrap to prevent transportation scratches and chloride ion corrosion.

- Custom foam channels with flanged curved surfaces for secure fixation, preventing structural deformation.

- Classified Packaging Strategy:

- Small sizes (≤6″): Grouped by specifications, separated by cardboard partitions before packing.

- Large sizes (>6″): Individually packaged in wooden boxes with built-in anti-vibration brackets.

- Error-proofing Identification System:

- Labels clearly marked with “Requires matching loose flange” and material code (e.g., “316L Stub End”).

- Outer boxes printed with flow direction arrows (to ensure correct flanged direction).

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.