علامات المنتجات الساخنة

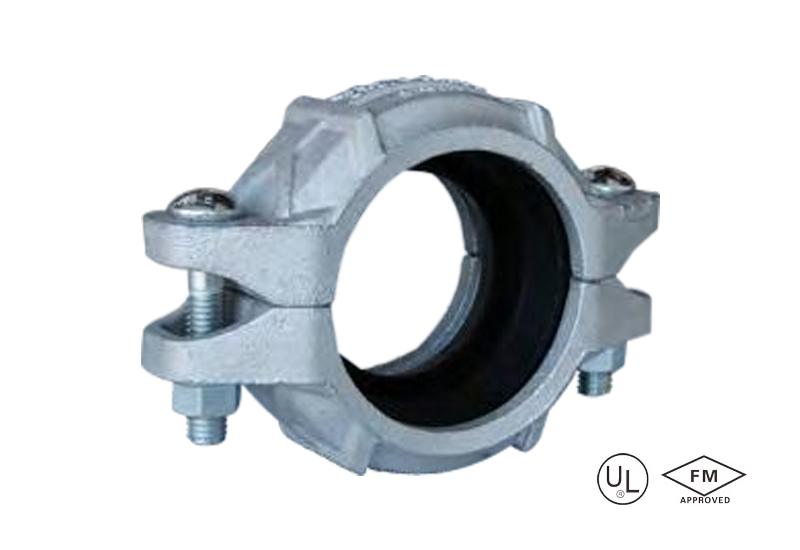

تقليل اقتران مخدد مرن مخدد

-معيار: ANSI / UL 213 UL / FM

-المواد: حديد الدكتايل ASTM A536 ASTM A536، 65-45-12

-البرغي والصمولة: الفولاذ الكربوني

-الحشية: EPDM، النتريل، مطاط السيليكون، إلخ

-معدل الضغط: 300 - 500 رطل لكل بوصة مربعة

-السطح: طلاء أحمر/مغلفن بالغمس الساخن

-نطاق الحجم: 1-1/2″×1-1/4″ - 8″×6″

الوصف

اقتران مخدد مرن مخفض هو وصلة أنابيب مرنة ذات قطر متغير، تستخدم لتوصيل الأنابيب ذات الأقطار المختلفة، مما يسمح بإزاحة نسبية معينة بين الأنابيب لتعويض التشوه أو امتصاص الاهتزاز

المواصفات

الحجم المتاح

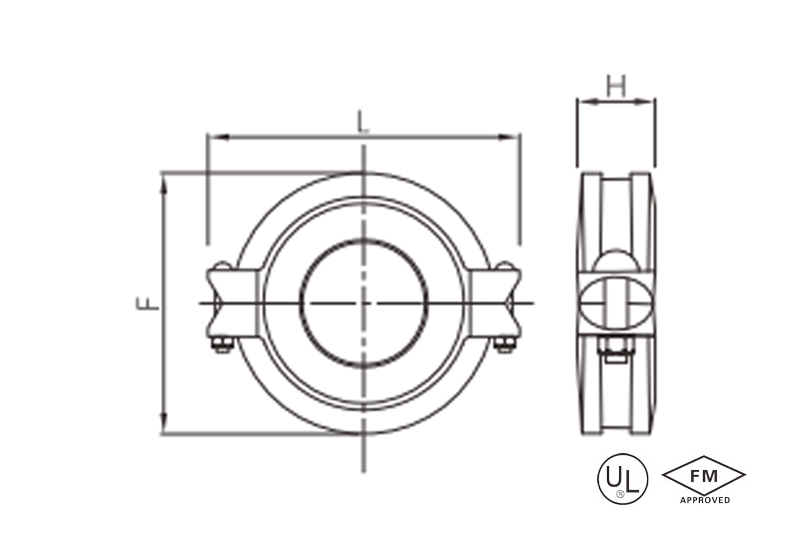

| الحجم | الأبعاد (مم) | التثبيت (ن x حجم البرغي) | |||||

| بوصة | دن | مم | F | L | H | ANSI | EN |

| 1-1/2″ × 1-1/4″ | 40 × 32 | 48.3 × 42.4 | 74 | 111 | 44 | 2 - 3/8″ × 45 | 2 - M10 × 45 |

| 2″ × 1-1/2″ | 50 × 40 | 60.3 × 48.3 | 86 | 125 | 44 | 2 - 3/8″ × 55 | 2 - M10 × 57 |

| 2-1/2″ × 1″ | 65 × 25 | 73.0 × 33.7 | 100 | 138 | 45 | 2 - 3/8″ × 55 | 2 - M10 × 57 |

| 2-1/2″ × 1-1/2″ | 65 × 40 | 73.0 × 48.3 | 101 | 137 | 48 | 2 - 3/8″ × 55 | 2 - M10 × 55 |

| 2-1/2″ × 2″ | 65 × 50 | 73.0 × 60.3 | 100 | 138 | 45 | 2 - 3/8″ × 55 | 2 - M10 × 57 |

| 2-1/2″ × 1″ | 65 × 25 | 76.1 × 33.7 | 102 | 140 | 45 | 2 - 3/8″ × 55 | 2 - M10 × 57 |

| 2-1/2″ × 1-1/2″ | 65 × 40 | 76.1 × 48.3 | 102 | 140 | 45 | 2 - 3/8″ × 55 | 2 - M10 × 57 |

| 2-1/2″ × 2″ | 65 × 50 | 76.1 × 60.3 | 102 | 144 | 45 | 2 - 3/8″ × 55 | 2 - M10 × 57 |

| 2-1/2″ × 2-1/2″ | 65 × 65 | 76.1 × 73.0 | 100 | 141 | 47 | 2 - 3/8″ × 55 | 2 - M10 × 55 |

| 3″ × 1″ | 80 × 25 | 88.9 × 33.7 | 115 | 168 | 46 | 2 - 1/2″ × 70 | 2 - M12 × 70 |

| 3″ × 1-1/2″ | 80 × 40 | 88.9 × 48.3 | 120 | 164 | 48 | 2 - 1/2″ × 65 | 2 - M12 × 65 |

| 3″ × 2″ | 80 × 50 | 88.9 × 60.3 | 115 | 168 | 46 | 2 - 1/2″ × 70 | 2 - M12 × 70 |

| 3″ × 2-1/2″ | 80 × 65 | 88.9 × 73.0 | 115 | 168 | 46 | 2 - 1/2″ × 70 | 2 - M12 × 70 |

| 3″ × 2-1/2″ | 80 × 65 | 88.9 × 76.1 | 115 | 172 | 46 | 2 - 1/2″ × 70 | 2 - M12 × 70 |

| 4″ × 1″ | 100 × 25 | 114.3 × 33.7 | 144 | 198 | 50 | 2 - 1/2″ × 70 | 2 - M12 × 70 |

| 4″ × 1-1/2″ | 100 × 40 | 114.3 × 48.3 | 150 | 195 | 49 | 2 - 1/2″ × 65 | 2 - M12 × 65 |

| 4″ × 2″ | 100 × 50 | 114.3 × 60.3 | 144 | 198 | 50 | 2 - 1/2″ × 70 | 2 - M12 × 70 |

| 4″ × 2-1/2″ | 100 × 65 | 114.3 × 73.0 | 144 | 198 | 50 | 2 - 1/2″ × 70 | 2 - M12 × 70 |

| 4″ × 2-1/2″ | 100 × 65 | 114.3 × 76.1 | 144 | 202 | 50 | 2 - 1/2″ × 70 | 2 - M12 × 70 |

| 4″ × 3″ | 100 × 80 | 114.3 × 88.9 | 148 | 198 | 50 | 2 - 1/2″ × 70 | 2 - M12 × 70 |

| 6″ × 3″ | 150 × 80 | 165.1 × 88.9 | 200 | 260 | 51 | 2 - 5/8″ × 85 | 2 - M16 × 85 |

| 6″ × 4″ | 150 × 100 | 165.1 × 114.3 | 200 | 260 | 51 | 2 - 5/8″ × 85 | 2 - M16 × 85 |

| 6″ × 3″ | 150 × 80 | 168.3 × 88.9 | 200 | 268 | 51 | 2 - 5/8″ × 85 | 2 - M16 × 85 |

| 6″ × 4″ | 150 × 100 | 168.3 × 114.3 | 203 | 268 | 53 | 2 - 5/8″ × 85 | 2 - M16 × 85 |

| 8″ × 6″ | 200 × 150 | 219.1 × 165.1 | 257 | 335 | 60 | 2 - 3/4″ × 115 | 2 - M20 × 115 |

| 8″ × 6″ | 200 × 150 | 219.1 × 168.3 | 260 | 338 | 60 | 2 - 3/4″ × 115 | 2 - M20 × 115 |

التطبيق

- تركيبات تحويل قطر الأنبوب: مفيدة للربط بين أحجام مختلفة من أقطار الأنابيب مثل 1½ بوصة إلى 1¼ بوصة و8 بوصة إلى 6 بوصة وما إلى ذلك، كما تستخدم لتقليل أو زيادة حجم الأنابيب داخل النظام.

- تكييف النظام الديناميكي: بالنسبة لمتطلبات التخميد الاهتزازية، الوصلة الانتقالية لقطر المضخة، والخط الفرعي لتكييف الهواء، وقسم واجهة قطر شبكة الحماية من الحرائق لتعويض الإزاحة.

- الأسلاك ذات المساحات المعقدة: بما في ذلك الأماكن التي يجب أن تتحول فيها الأنابيب وتتصل ببعضها البعض في المناطق ذات المساحات الضيقة (مثل غرف المعدات وأنفاق المرافق تحت الأرض).

- مرافق عالمية المستوى: UL/FM: أعلى معيار لشهادة المعدات معتمد للاستخدام في المستشفيات والمصانع وغيرها من أنظمة خطوط الأنابيب عالية الموثوقية؛ لا يوجد فاصل زمني للتسرب

المزايا

1. اتصال مزدوج الوظيفة: يمكن التعامل معها بشكل جيد على انتقال الحجم، ولكن يمكنك أيضًا أن تلعب دورًا في التعويض المرن، وحفظ استخدام خط الأنابيب ومتصل بأجزاء في الاعتبار.

2. التصحيح التلقائي للتمدد الحراري والانكماش أو الاهتزاز بسبب إزاحة خط الأنابيب، ومنع تغير الحجم تركيز الإجهاد المحلي الناجم عن الكسر;

3. حشيات - حشية مطاطية مانعة للتسرب (مصممة من مادة EPDM) لتأمين تسرب الماء أو الزيت أو الغاز من الوسائط ومتانة لمنطقة الضغط المتوسط العالي

4. تحسين كفاءة التركيب: تصميم الأخدود خالٍ من اللحام أو المحاذاة المعقدة؛ يمكن أن يحقق إحكام ربط تحويل القطر.

5. مع انخفاض تكاليف الصيانة: يمكن تفكيك جميع الأجزاء بسرعة واستبدالها دون الحاجة إلى قطع أنابيب ذات أقطار مختلفة مما يؤدي إلى توفير الوقت والنفقات للصيانة.

التعبئة

- حماية مخصصة:

- كل قطعة مصنوعة خصيصًا مع بطانة من الفوم داخل صندوق من الورق المقوى وفقًا لقطر الأنبوب في كلا الطرفين (على سبيل المثال، مع وضع علامة على النحو التالي: مخفض 4 × 3 بوصة × 3 بوصة).

- يتضمن الصندوق حقيبة مقاومة للرطوبة وتعليمات تركيب بسيطة.

- حل التعزيز للأجزاء غير منتظمة الشكل:

- بالنسبة للأحجام من 6 بوصات وما فوق، يتم استخدام صناديق خشبية مقسمة لعزل وحماية هياكل الشفة ذات الأحجام المختلفة في كلا الطرفين.

- حماية النقل بالجملة:

- يتم تغليف كل صنف على حدة ووضعه في طبقات على منصة نقالة، وتثبيته بغشاء مطاطي وأشرطة فولاذية لمنع التشوه الناتج عن صدمات النقل.

الحجم المتاح

| الحجم | الأبعاد (مم) | التثبيت (ن x حجم البرغي) | |||||

| بوصة | دن | مم | F | L | H | ANSI | EN |

| 1-1/2″ × 1-1/4″ | 40 × 32 | 48.3 × 42.4 | 74 | 111 | 44 | 2 - 3/8″ × 45 | 2 - M10 × 45 |

| 2″ × 1-1/2″ | 50 × 40 | 60.3 × 48.3 | 86 | 125 | 44 | 2 - 3/8″ × 55 | 2 - M10 × 57 |

| 2-1/2″ × 1″ | 65 × 25 | 73.0 × 33.7 | 100 | 138 | 45 | 2 - 3/8″ × 55 | 2 - M10 × 57 |

| 2-1/2″ × 1-1/2″ | 65 × 40 | 73.0 × 48.3 | 101 | 137 | 48 | 2 - 3/8″ × 55 | 2 - M10 × 55 |

| 2-1/2″ × 2″ | 65 × 50 | 73.0 × 60.3 | 100 | 138 | 45 | 2 - 3/8″ × 55 | 2 - M10 × 57 |

| 2-1/2″ × 1″ | 65 × 25 | 76.1 × 33.7 | 102 | 140 | 45 | 2 - 3/8″ × 55 | 2 - M10 × 57 |

| 2-1/2″ × 1-1/2″ | 65 × 40 | 76.1 × 48.3 | 102 | 140 | 45 | 2 - 3/8″ × 55 | 2 - M10 × 57 |

| 2-1/2″ × 2″ | 65 × 50 | 76.1 × 60.3 | 102 | 144 | 45 | 2 - 3/8″ × 55 | 2 - M10 × 57 |

| 2-1/2″ × 2-1/2″ | 65 × 65 | 76.1 × 73.0 | 100 | 141 | 47 | 2 - 3/8″ × 55 | 2 - M10 × 55 |

| 3″ × 1″ | 80 × 25 | 88.9 × 33.7 | 115 | 168 | 46 | 2 - 1/2″ × 70 | 2 - M12 × 70 |

| 3″ × 1-1/2″ | 80 × 40 | 88.9 × 48.3 | 120 | 164 | 48 | 2 - 1/2″ × 65 | 2 - M12 × 65 |

| 3″ × 2″ | 80 × 50 | 88.9 × 60.3 | 115 | 168 | 46 | 2 - 1/2″ × 70 | 2 - M12 × 70 |

| 3″ × 2-1/2″ | 80 × 65 | 88.9 × 73.0 | 115 | 168 | 46 | 2 - 1/2″ × 70 | 2 - M12 × 70 |

| 3″ × 2-1/2″ | 80 × 65 | 88.9 × 76.1 | 115 | 172 | 46 | 2 - 1/2″ × 70 | 2 - M12 × 70 |

| 4″ × 1″ | 100 × 25 | 114.3 × 33.7 | 144 | 198 | 50 | 2 - 1/2″ × 70 | 2 - M12 × 70 |

| 4″ × 1-1/2″ | 100 × 40 | 114.3 × 48.3 | 150 | 195 | 49 | 2 - 1/2″ × 65 | 2 - M12 × 65 |

| 4″ × 2″ | 100 × 50 | 114.3 × 60.3 | 144 | 198 | 50 | 2 - 1/2″ × 70 | 2 - M12 × 70 |

| 4″ × 2-1/2″ | 100 × 65 | 114.3 × 73.0 | 144 | 198 | 50 | 2 - 1/2″ × 70 | 2 - M12 × 70 |

| 4″ × 2-1/2″ | 100 × 65 | 114.3 × 76.1 | 144 | 202 | 50 | 2 - 1/2″ × 70 | 2 - M12 × 70 |

| 4″ × 3″ | 100 × 80 | 114.3 × 88.9 | 148 | 198 | 50 | 2 - 1/2″ × 70 | 2 - M12 × 70 |

| 6″ × 3″ | 150 × 80 | 165.1 × 88.9 | 200 | 260 | 51 | 2 - 5/8″ × 85 | 2 - M16 × 85 |

| 6″ × 4″ | 150 × 100 | 165.1 × 114.3 | 200 | 260 | 51 | 2 - 5/8″ × 85 | 2 - M16 × 85 |

| 6″ × 3″ | 150 × 80 | 168.3 × 88.9 | 200 | 268 | 51 | 2 - 5/8″ × 85 | 2 - M16 × 85 |

| 6″ × 4″ | 150 × 100 | 168.3 × 114.3 | 203 | 268 | 53 | 2 - 5/8″ × 85 | 2 - M16 × 85 |

| 8″ × 6″ | 200 × 150 | 219.1 × 165.1 | 257 | 335 | 60 | 2 - 3/4″ × 115 | 2 - M20 × 115 |

| 8″ × 6″ | 200 × 150 | 219.1 × 168.3 | 260 | 338 | 60 | 2 - 3/4″ × 115 | 2 - M20 × 115 |

- تركيبات تحويل قطر الأنبوب: مفيدة للربط بين أحجام مختلفة من أقطار الأنابيب مثل 1½ بوصة إلى 1¼ بوصة و8 بوصة إلى 6 بوصة وما إلى ذلك، كما تستخدم لتقليل أو زيادة حجم الأنابيب داخل النظام.

- تكييف النظام الديناميكي: بالنسبة لمتطلبات التخميد الاهتزازية، الوصلة الانتقالية لقطر المضخة، والخط الفرعي لتكييف الهواء، وقسم واجهة قطر شبكة الحماية من الحرائق لتعويض الإزاحة.

- الأسلاك ذات المساحات المعقدة: بما في ذلك الأماكن التي يجب أن تتحول فيها الأنابيب وتتصل ببعضها البعض في المناطق ذات المساحات الضيقة (مثل غرف المعدات وأنفاق المرافق تحت الأرض).

- مرافق عالمية المستوى: UL/FM: أعلى معيار لشهادة المعدات معتمد للاستخدام في المستشفيات والمصانع وغيرها من أنظمة خطوط الأنابيب عالية الموثوقية؛ لا يوجد فاصل زمني للتسرب

1. اتصال مزدوج الوظيفة: يمكن التعامل معها بشكل جيد على انتقال الحجم، ولكن يمكنك أيضًا أن تلعب دورًا في التعويض المرن، وحفظ استخدام خط الأنابيب ومتصل بأجزاء في الاعتبار.

2. التصحيح التلقائي للتمدد الحراري والانكماش أو الاهتزاز بسبب إزاحة خط الأنابيب، ومنع تغير الحجم تركيز الإجهاد المحلي الناجم عن الكسر;

3. حشيات - حشية مطاطية مانعة للتسرب (مصممة من مادة EPDM) لتأمين تسرب الماء أو الزيت أو الغاز من الوسائط ومتانة لمنطقة الضغط المتوسط العالي

4. تحسين كفاءة التركيب: تصميم الأخدود خالٍ من اللحام أو المحاذاة المعقدة؛ يمكن أن يحقق إحكام ربط تحويل القطر.

5. مع انخفاض تكاليف الصيانة: يمكن تفكيك جميع الأجزاء بسرعة واستبدالها دون الحاجة إلى قطع أنابيب ذات أقطار مختلفة مما يؤدي إلى توفير الوقت والنفقات للصيانة.

- حماية مخصصة:

- كل قطعة مصنوعة خصيصًا مع بطانة من الفوم داخل صندوق من الورق المقوى وفقًا لقطر الأنبوب في كلا الطرفين (على سبيل المثال، مع وضع علامة على النحو التالي: مخفض 4 × 3 بوصة × 3 بوصة).

- يتضمن الصندوق حقيبة مقاومة للرطوبة وتعليمات تركيب بسيطة.

- حل التعزيز للأجزاء غير منتظمة الشكل:

- بالنسبة للأحجام من 6 بوصات وما فوق، يتم استخدام صناديق خشبية مقسمة لعزل وحماية هياكل الشفة ذات الأحجام المختلفة في كلا الطرفين.

- حماية النقل بالجملة:

- يتم تغليف كل صنف على حدة ووضعه في طبقات على منصة نقالة، وتثبيته بغشاء مطاطي وأشرطة فولاذية لمنع التشوه الناتج عن صدمات النقل.

احصل على عرض أسعار أنابيب الصلب المخصصة اليوم!

زوّدنا بتفاصيل مشروعك (مثل التطبيق والمواصفات والكمية). سيقدم لك فريقنا المتمرس حلاً مخصصاً وعرض أسعار تنافسي في غضون 24 ساعة عمل.