HOT PRODUCTS TAGS

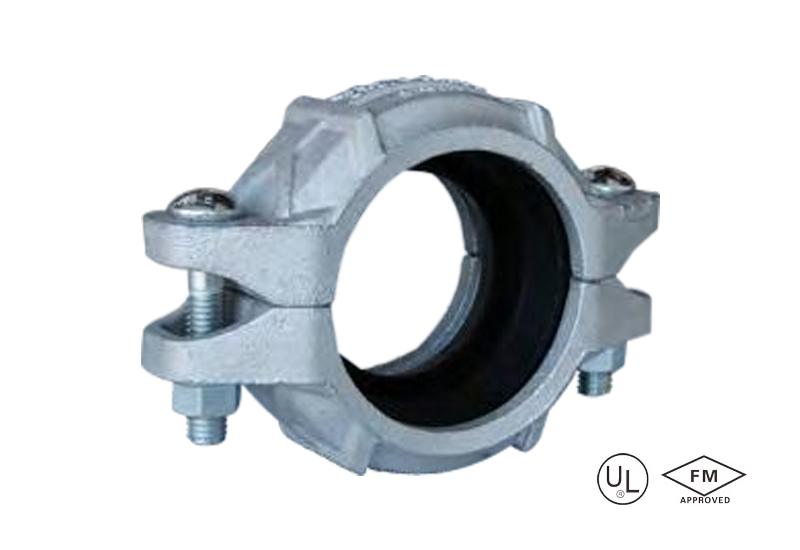

Reducing flexible grooved coupling

·Standard: ANSI / UL 213 UL / FM

·Material: Ductile iron ASTM A536, 65-45-12

·Bolt & nut: Carbon steel

·Gasket: EPDM, nitrile, silicone rubber, etc

·Rated pressure: 300 – 500 psi

·Surface: Red painting / hot dip galvanized

·Size range: 1-1/2″×1-1/4″ – 8″×6″

description

Reducing flexible grooved coupling is a variable diameter flexible pipe joint, used to connect pipes of different diameters, allowing for a certain relative displacement between pipes to compensate for deformation or absorb vibration

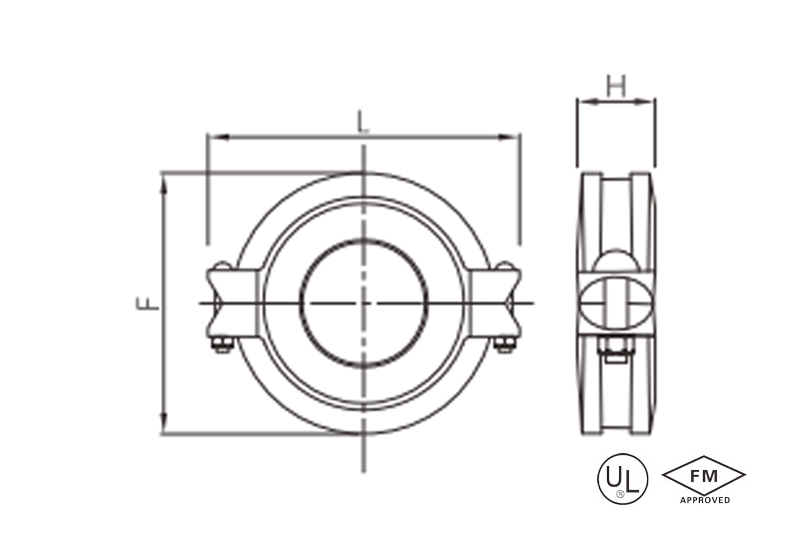

Specification

Available size

| Size | Dimension (mm) | Bolting (n x bolt size) | |||||

| Inch | DN | mm | F | L | H | ANSI | EN |

| 1-1/2″ × 1-1/4″ | 40 × 32 | 48.3 × 42.4 | 74 | 111 | 44 | 2 – 3/8″ × 45 | 2 – M10 × 45 |

| 2″ × 1-1/2″ | 50 × 40 | 60.3 × 48.3 | 86 | 125 | 44 | 2 – 3/8″ × 55 | 2 – M10 × 57 |

| 2-1/2″ × 1″ | 65 × 25 | 73.0 × 33.7 | 100 | 138 | 45 | 2 – 3/8″ × 55 | 2 – M10 × 57 |

| 2-1/2″ × 1-1/2″ | 65 × 40 | 73.0 × 48.3 | 101 | 137 | 48 | 2 – 3/8″ × 55 | 2 – M10 × 55 |

| 2-1/2″ × 2″ | 65 × 50 | 73.0 × 60.3 | 100 | 138 | 45 | 2 – 3/8″ × 55 | 2 – M10 × 57 |

| 2-1/2″ × 1″ | 65 × 25 | 76.1 × 33.7 | 102 | 140 | 45 | 2 – 3/8″ × 55 | 2 – M10 × 57 |

| 2-1/2″ × 1-1/2″ | 65 × 40 | 76.1 × 48.3 | 102 | 140 | 45 | 2 – 3/8″ × 55 | 2 – M10 × 57 |

| 2-1/2″ × 2″ | 65 × 50 | 76.1 × 60.3 | 102 | 144 | 45 | 2 – 3/8″ × 55 | 2 – M10 × 57 |

| 2-1/2″ × 2-1/2″ | 65 × 65 | 76.1 × 73.0 | 100 | 141 | 47 | 2 – 3/8″ × 55 | 2 – M10 × 55 |

| 3″ × 1″ | 80 × 25 | 88.9 × 33.7 | 115 | 168 | 46 | 2 – 1/2″ × 70 | 2 – M12 × 70 |

| 3″ × 1-1/2″ | 80 × 40 | 88.9 × 48.3 | 120 | 164 | 48 | 2 – 1/2″ × 65 | 2 – M12 × 65 |

| 3″ × 2″ | 80 × 50 | 88.9 × 60.3 | 115 | 168 | 46 | 2 – 1/2″ × 70 | 2 – M12 × 70 |

| 3″ × 2-1/2″ | 80 × 65 | 88.9 × 73.0 | 115 | 168 | 46 | 2 – 1/2″ × 70 | 2 – M12 × 70 |

| 3″ × 2-1/2″ | 80 × 65 | 88.9 × 76.1 | 115 | 172 | 46 | 2 – 1/2″ × 70 | 2 – M12 × 70 |

| 4″ × 1″ | 100 × 25 | 114.3 × 33.7 | 144 | 198 | 50 | 2 – 1/2″ × 70 | 2 – M12 × 70 |

| 4″ × 1-1/2″ | 100 × 40 | 114.3 × 48.3 | 150 | 195 | 49 | 2 – 1/2″ × 65 | 2 – M12 × 65 |

| 4″ × 2″ | 100 × 50 | 114.3 × 60.3 | 144 | 198 | 50 | 2 – 1/2″ × 70 | 2 – M12 × 70 |

| 4″ × 2-1/2″ | 100 × 65 | 114.3 × 73.0 | 144 | 198 | 50 | 2 – 1/2″ × 70 | 2 – M12 × 70 |

| 4″ × 2-1/2″ | 100 × 65 | 114.3 × 76.1 | 144 | 202 | 50 | 2 – 1/2″ × 70 | 2 – M12 × 70 |

| 4″ × 3″ | 100 × 80 | 114.3 × 88.9 | 148 | 198 | 50 | 2 – 1/2″ × 70 | 2 – M12 × 70 |

| 6″ × 3″ | 150 × 80 | 165.1 × 88.9 | 200 | 260 | 51 | 2 – 5/8″ × 85 | 2 – M16 × 85 |

| 6″ × 4″ | 150 × 100 | 165.1 × 114.3 | 200 | 260 | 51 | 2 – 5/8″ × 85 | 2 – M16 × 85 |

| 6″ × 3″ | 150 × 80 | 168.3 × 88.9 | 200 | 268 | 51 | 2 – 5/8″ × 85 | 2 – M16 × 85 |

| 6″ × 4″ | 150 × 100 | 168.3 × 114.3 | 203 | 268 | 53 | 2 – 5/8″ × 85 | 2 – M16 × 85 |

| 8″ × 6″ | 200 × 150 | 219.1 × 165.1 | 257 | 335 | 60 | 2 – 3/4″ × 115 | 2 – M20 × 115 |

| 8″ × 6″ | 200 × 150 | 219.1 × 168.3 | 260 | 338 | 60 | 2 – 3/4″ × 115 | 2 – M20 × 115 |

application

- Pipe Diameter Transition Fittings: Beneficial for joining different sizes of pipe diameters i.e. 1½-inch to 1¼-inch,8-inch to 6-inch etc as well as used for reducing or increasing the size of pipes within the system.

- Dynamic system adaptation: For vibration damping requirements, the pump diameter transition junction, air conditioning branch line, fire protection network diameter interface section for displacement compensation.

- Complex Space Wiring: Including where pipes must turn and interconnect in space constrained areas (e.g., equipment rooms, underground utility tunnels).

- World-Class Facilities: UL/FM : The highest equipment certification standard certified for use in hospitals, factories and other high reliability pipeline systems; NO LEAKage interval

advantages

1. Dual-function connection: can be well handled on the size transition, but also you could play a role in flexible compensation, save use of pipeline and connected with parts into account.

2. Automatic correction of thermal expansion and contraction or vibration due to displacement of the pipeline, prevent size change local stress concentration caused by fracture;

3. Gaskets — rubber sealing gasket (EPDM designed) to secure water, oil or gas media leakage and durability for medium-high pressure area

4. Installation efficiency enhanced: Groove design is free to weld or complex alignment; tightening a bolt can realize the diameter conversion connection.

5. With low maintenance costs: all parts can be disassembled quickly and replaced without the need to cut different diameter pipes resulting in time and expense savings for maintenance.

packing

- Customized Protection:

- Each piece is custom-made with foam lining inside a cardboard box according to the pipe diameter at both ends (e.g., marked as: reducer 4”×3”).

- The box includes a moisture-proof bag and simple installation instructions.

- Reinforcement solution for irregularly shaped parts:

- For sizes of 6 inches and above, compartmentalized wooden boxes are used to isolate and protect the different-sized flange structures at both ends.

- Bulk transportation protection:

- Each item is individually packaged and layered on a pallet, secured with stretch film and steel straps to prevent deformation from transportation impacts.

Available size

| Size | Dimension (mm) | Bolting (n x bolt size) | |||||

| Inch | DN | mm | F | L | H | ANSI | EN |

| 1-1/2″ × 1-1/4″ | 40 × 32 | 48.3 × 42.4 | 74 | 111 | 44 | 2 – 3/8″ × 45 | 2 – M10 × 45 |

| 2″ × 1-1/2″ | 50 × 40 | 60.3 × 48.3 | 86 | 125 | 44 | 2 – 3/8″ × 55 | 2 – M10 × 57 |

| 2-1/2″ × 1″ | 65 × 25 | 73.0 × 33.7 | 100 | 138 | 45 | 2 – 3/8″ × 55 | 2 – M10 × 57 |

| 2-1/2″ × 1-1/2″ | 65 × 40 | 73.0 × 48.3 | 101 | 137 | 48 | 2 – 3/8″ × 55 | 2 – M10 × 55 |

| 2-1/2″ × 2″ | 65 × 50 | 73.0 × 60.3 | 100 | 138 | 45 | 2 – 3/8″ × 55 | 2 – M10 × 57 |

| 2-1/2″ × 1″ | 65 × 25 | 76.1 × 33.7 | 102 | 140 | 45 | 2 – 3/8″ × 55 | 2 – M10 × 57 |

| 2-1/2″ × 1-1/2″ | 65 × 40 | 76.1 × 48.3 | 102 | 140 | 45 | 2 – 3/8″ × 55 | 2 – M10 × 57 |

| 2-1/2″ × 2″ | 65 × 50 | 76.1 × 60.3 | 102 | 144 | 45 | 2 – 3/8″ × 55 | 2 – M10 × 57 |

| 2-1/2″ × 2-1/2″ | 65 × 65 | 76.1 × 73.0 | 100 | 141 | 47 | 2 – 3/8″ × 55 | 2 – M10 × 55 |

| 3″ × 1″ | 80 × 25 | 88.9 × 33.7 | 115 | 168 | 46 | 2 – 1/2″ × 70 | 2 – M12 × 70 |

| 3″ × 1-1/2″ | 80 × 40 | 88.9 × 48.3 | 120 | 164 | 48 | 2 – 1/2″ × 65 | 2 – M12 × 65 |

| 3″ × 2″ | 80 × 50 | 88.9 × 60.3 | 115 | 168 | 46 | 2 – 1/2″ × 70 | 2 – M12 × 70 |

| 3″ × 2-1/2″ | 80 × 65 | 88.9 × 73.0 | 115 | 168 | 46 | 2 – 1/2″ × 70 | 2 – M12 × 70 |

| 3″ × 2-1/2″ | 80 × 65 | 88.9 × 76.1 | 115 | 172 | 46 | 2 – 1/2″ × 70 | 2 – M12 × 70 |

| 4″ × 1″ | 100 × 25 | 114.3 × 33.7 | 144 | 198 | 50 | 2 – 1/2″ × 70 | 2 – M12 × 70 |

| 4″ × 1-1/2″ | 100 × 40 | 114.3 × 48.3 | 150 | 195 | 49 | 2 – 1/2″ × 65 | 2 – M12 × 65 |

| 4″ × 2″ | 100 × 50 | 114.3 × 60.3 | 144 | 198 | 50 | 2 – 1/2″ × 70 | 2 – M12 × 70 |

| 4″ × 2-1/2″ | 100 × 65 | 114.3 × 73.0 | 144 | 198 | 50 | 2 – 1/2″ × 70 | 2 – M12 × 70 |

| 4″ × 2-1/2″ | 100 × 65 | 114.3 × 76.1 | 144 | 202 | 50 | 2 – 1/2″ × 70 | 2 – M12 × 70 |

| 4″ × 3″ | 100 × 80 | 114.3 × 88.9 | 148 | 198 | 50 | 2 – 1/2″ × 70 | 2 – M12 × 70 |

| 6″ × 3″ | 150 × 80 | 165.1 × 88.9 | 200 | 260 | 51 | 2 – 5/8″ × 85 | 2 – M16 × 85 |

| 6″ × 4″ | 150 × 100 | 165.1 × 114.3 | 200 | 260 | 51 | 2 – 5/8″ × 85 | 2 – M16 × 85 |

| 6″ × 3″ | 150 × 80 | 168.3 × 88.9 | 200 | 268 | 51 | 2 – 5/8″ × 85 | 2 – M16 × 85 |

| 6″ × 4″ | 150 × 100 | 168.3 × 114.3 | 203 | 268 | 53 | 2 – 5/8″ × 85 | 2 – M16 × 85 |

| 8″ × 6″ | 200 × 150 | 219.1 × 165.1 | 257 | 335 | 60 | 2 – 3/4″ × 115 | 2 – M20 × 115 |

| 8″ × 6″ | 200 × 150 | 219.1 × 168.3 | 260 | 338 | 60 | 2 – 3/4″ × 115 | 2 – M20 × 115 |

- Pipe Diameter Transition Fittings: Beneficial for joining different sizes of pipe diameters i.e. 1½-inch to 1¼-inch,8-inch to 6-inch etc as well as used for reducing or increasing the size of pipes within the system.

- Dynamic system adaptation: For vibration damping requirements, the pump diameter transition junction, air conditioning branch line, fire protection network diameter interface section for displacement compensation.

- Complex Space Wiring: Including where pipes must turn and interconnect in space constrained areas (e.g., equipment rooms, underground utility tunnels).

- World-Class Facilities: UL/FM : The highest equipment certification standard certified for use in hospitals, factories and other high reliability pipeline systems; NO LEAKage interval

1. Dual-function connection: can be well handled on the size transition, but also you could play a role in flexible compensation, save use of pipeline and connected with parts into account.

2. Automatic correction of thermal expansion and contraction or vibration due to displacement of the pipeline, prevent size change local stress concentration caused by fracture;

3. Gaskets — rubber sealing gasket (EPDM designed) to secure water, oil or gas media leakage and durability for medium-high pressure area

4. Installation efficiency enhanced: Groove design is free to weld or complex alignment; tightening a bolt can realize the diameter conversion connection.

5. With low maintenance costs: all parts can be disassembled quickly and replaced without the need to cut different diameter pipes resulting in time and expense savings for maintenance.

- Customized Protection:

- Each piece is custom-made with foam lining inside a cardboard box according to the pipe diameter at both ends (e.g., marked as: reducer 4”×3”).

- The box includes a moisture-proof bag and simple installation instructions.

- Reinforcement solution for irregularly shaped parts:

- For sizes of 6 inches and above, compartmentalized wooden boxes are used to isolate and protect the different-sized flange structures at both ends.

- Bulk transportation protection:

- Each item is individually packaged and layered on a pallet, secured with stretch film and steel straps to prevent deformation from transportation impacts.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.