A Guide to Offshore Steel Pipe & Tubes for Subsea Projects

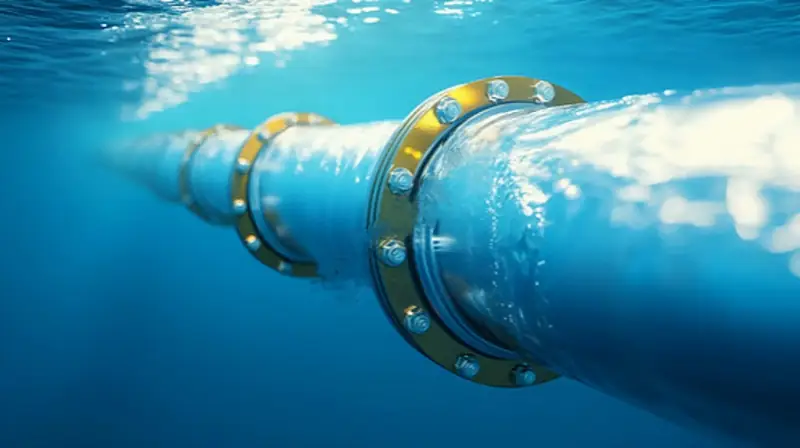

The vast expanse of our oceans hides a complex network of arteries vital to the global energy supply chain:offshore pipelines. These submerged lifelines, primarily constructed from the specialized offshore pipe, transport oil, natural gas, and sometimes water across challenging underwater terrains, connecting the remote reservoirs to processing facilities and ultimately to the consumers worldwide. Understanding the technology, materials, and engineering behind these offshore steel pipe is the key to appreciating their immense economic and strategic importance.

The Backbone of Subsea Transport: Offshore Line Pipe

At the heart of any major subsea transmission system lies the offshore line pipe.It’s engineered to withstand the extreme conditions. Think crushing depths, immense internal pressure from hydrocarbons, corrosive seawater, potential impacts, and constant dynamic stresses from currents. Offshore line pipe is typically:

1. High-Strength Steel:It is made from specially formulated carbon or low-alloy steels meeting the stringent international standards (like API 5L). Grades like X65, X70, and even higher are common, providing the necessary yield strength.

2. Corrosion-Resistant:It is protected by advanced coatings FBE steel pipe, 3LPE steel pipe, 3LPP steel pipe) and often supplemented by the sacrificial anode Cathodic Protection (CP) systems to combat the relentless attack of the seawater and transported fluids.

3. Precision Manufactured:Seamless or longitudinally/submerged arc welded (SAWL/SAWH) pipes undergo the rigorous testing (ultrasonic, hydrostatic, dimensional) to ensure integrity before leaving the mill.

4. Sized for Purpose:The diameters can range from a few inches for the utility lines to over 40 inches for the major export trunk lines. Wall thickness is carefully calculated based on the water depth, pressure, and required safety factors.

In marine pipeline engineering, LSAW steel pipe (longitudinal submerged arc welded pipes) and SSAW Steel pipe (spiral submerged arc welded pipes) are applied in different scenarios due to their structural characteristics and process advantages:

I. Applicable scenarios and technical characteristics

LSAW pipeline applications

High-pressure mainlines: Due to their high structural strength and dimensional accuracy, LSAW pipes are suitable for high-pressure oil/gas transmission pipelines, particularly in critical sections of deep-water areas where high pressure must be withstood.

Corrosion protection requirements: Enhanced resistance to seawater corrosion and extended service life are achieved through corrosion-resistant coatings such as 3PE (three-layer polyethylene) or FBE (fused epoxy powder).

Manufacturing Process: The JCOE forming process ensures pipe diameter accuracy, meeting sealing requirements in high-pressure environments.

SSAW Pipeline Applications

Large-Diameter Transmission Pipelines: The spiral structure allows for flexible manufacturing of ultra-large-diameter pipes (e.g., 3000 mm), suitable for high-volume crude oil or natural gas branch pipelines.

Terrain Adaptability: The ductility of spiral welds is better suited for laying in complex underwater terrains, reducing the risk of stress concentration.

Cost and Efficiency: The continuous coil forming process reduces manufacturing costs, making it suitable for large-scale laying of medium- and low-pressure auxiliary pipelines.

ALLLAND STEEL PIPE PRODUCTION STANDARD

| PIPE TYPE | STANDARD | KEY INDICATORS |

| LSAW STEEL PIPE | API 5L, DNV-OS-F101 | High pressure strength, dimensional accuracy |

| SSAW STEEL PIPE | GB/T 9711, ISO 3183 | Resilience and ductility |

Beyond the Trunkline: The Versatility of Offshore Tubes and Piping

While the large-diameter offshore line pipe carries the bulk of hydrocarbons, the term offshore tubes often refers to the smaller diameter conduits essential for the functioning of the offshore infrastructure. These offshore tubes serve the critical auxiliary roles:

1.Hydraulic Control Lines: The small-diameter tubes transmitting the hydraulic fluid to operate subsea valves, chokes, and control modules on the wells and manifolds.

2.Chemical Injection Lines:The tubes could carry corrosion inhibitors, scale preventers, or hydrate suppressants directly into the main flowline or wellbore.

3.Instrumentation and Sensing Lines:Tubes could connect the pressure, temperature, or erosion sensors to the surface monitoring systems.

4.Utility Lines:It could Carry the fuel, water, or air for the various platform or subsea operations.

5.Jacket Piling and Conductor Casing: While larger, the tubes are also used for structurally within platform jackets or as well conductors.

These offshore tubes are also predominantly steel (often stainless steel like 316L for the enhanced corrosion resistance in the critical applications) and require similar, if not more specialized, corrosion protection due to their smaller size and vulnerability.

Why Offshore Steel Pipe Reigns Supreme

The offshore steel pipe remains the undisputed material of the choice for primary subsea infrastructure for the compelling reasons:

1.Superior strength-to-weight ratio: The steel could provide the necessary structural integrity to the withstand immense hydrostatic pressure at the depth and internal operating pressures, without becoming prohibitively heavy for the installation.

2. Proven Durability: With the proper metallurgy, manufacturing, and the corrosion protection (coatings + CP), the steel pipelines have demonstrable lifespans could exceed 30-40 years in the harsh marine environments.

3. Weldability:The steel pipes could reliably welded offshore using the specialized techniques (e.g., hyperbaric welding, J-lay/S-lay welding), enabling the construction of continuous pipelines over the vast distances.

4. Availability and Scalability: The global steel industry could produce the massive quantities and the wide range of sizes/grades required for the major offshore projects.

5. Predictable Performance: Decades of engineering experience and the established standards (API, DNV, ISO) could provide the high confidence in the design and performance of offshore steel pipe*systems.

Conquering the Challenges: From Factory to Seabed

Installing an offshore pipe is a monumental feat of the marine engineering:

1. Route Survey & Preparation: Detailed seabed mapping to identify the hazards, plan the route, and potentially prepare the trench.

2. Pipe Lay Vessels: Specialized ships (S-lay, J-lay, Reel-lay) weld individual joints or spools of offshore line pipe into the continuous string and lower it could precisely to the seabed as the vessel moves forward. Dynamic positioning systems hold the vessel on course.

3. Trenching & Burial: For stability and protection (especially in shallow waters or fishing zones), the pipelines are often buried using jet trenchers or mechanical cutters. Rock dumping might provide the additional protection.

4. Tie-ins & Testing:It could connect the pipeline segments (subsea or above water) and rigorous hydrotesting ensure the integrity before commissioning.

5. Protection: Anode the installation for CP , in some cases, concrete weight coating for stability on the seabed.

Inspection & Integrity: Safeguarding the Lifeline

The journey doesn’t end at installation. Continuous monitoring is vital:

1.Pigging:”Smart pigs” (Pipeline Inspection Gauges) equipped with the sensors travel inside the offshore pipe, detecting corrosion, dents, cracks, or wax buildup.

2.ROV Surveys: Remotely Operated Vehicles visually inspect the pipeline exterior, anodes, and the seabed conditions.

3.Cathodic Protection Monitoring:Regular checks ensure the CP system is functioning effectively to the prevent corrosion.

4.Leak Detection Systems: Sophisticated flow could monitor and acoustic sensors and provide early warnings.

The Future Flows Through Offshore Pipes

As the exploration pushes into deeper waters and harsher environments (Arctic, ultra-deep), the demands on offshore steel pipe and offshore tubes grow. Innovations focus on:

1.Enhanced Materials:Development of the higher-strength steels (X80, X100+), corrosion-resistant alloys (CRAs), and composite materials for the specific applications.

2.Improved Coatings: Longer-lasting, more damage-resistant coating systems.

3.Advanced Installation Techniques: More efficient lay methods, deeper water capabilities.

4.Digital Twins & AI: Using the real-time data for predictive maintenance and optimized integrity management.

Conclusion

The unseen network of offshore pipes and offshore tubes is a testament to the human ingenuity in harnessing energy resources beneath the ocean. From the massive offshore line pipe transporting millions of barrels of the oil equivalent to the intricate offshore tubes enabling precise the control and chemical injection, specialized the offshore steel pipe forms the resilient backbone of this critical infrastructure. Continuous advancements in the materials, engineering, and integrity management ensure these vital subsea arteries will safely and efficiently fuel the global economy for decades to come, navigating the immense pressures of the deep. The reliable flow of the offshore energy truly begins with the strength and precision of the pipe laid on the ocean floor.

Frequently Asked Questions (FAQs)

1. Q: What’s the main difference between “offshore pipe” and “offshore tubes”?

A:”Offshore pipe” is the broader term encompassing the large-diameter transmission pipelines (offshore line pipe). “Offshore tubes” typically refer to the smaller-diameter conduits used for control, chemical injection, instrumentation, and utilities within offshore facilities.

2. Q: Why is steel the primary material for offshore pipelines?

A: Offshore steel pipe could offer the ideal combination of high strength,durability,weldability,performance in the harsh environments, and scalability for the large projects. Its strength-to-weight ratio is crucial for deep water applications.

3. Q: How are offshore pipelines protected from corrosion?

A: They use a dual system: (1) High-performance external coatings (like FBE, 3LPE, 3LPP) form a physical barrier. (2) Cathodic Protection (CP) systems, using the sacrificial anodes or impressed current, provide electro chemical protection to any exposed steel.

4. Q: How are pipelines installed on the seabed?

A: Specialized Pipe Lay Vessels (using S-lay, J-lay, or Reel-lay methods) weld pipe sections together and lower the continuous string to the seabed as the vessel moves. Trenching or rock dumping often follows for the protection.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.

Related Articles

ASTM A53 vs. API 5L: A Guide to Selection and Application

Introduction:Technology differences determine success or failure, and selection needs to be “precise”

Steel Density Analysis: Core Differences between Mild and Medium Carbon Steels and Industrial Applications

3LPE coated steel pipe: a solid barrier in the field of industrial corrosion protection

3LPP coated pipe: anti-corrosion guard in high temperature and high pressure environment

FBE steel pipe: the technological armor of the steel defense line

HOT TAGS

latest posts

- FBE steel pipe: the technological armor of the steel defense line

- Precision Engineering Redefined Dubai’s Stadium Dome Construction

- An Engineer’s Guide: A Deep Dive into UOE vs. JCOE LSAW Steel Pipe Manufacturing

- Floating Pipelines: Key Views on Offshore Dynamic Risers & Marine Transportation Pipelines

- The Dance of Spiral Forming: How SSAW Steel Pipes Are Made