Abrasion Resistant Steel Pipe for Mining: Why Wall Thickness Matters

In copper, iron or gold mines, slurry is much more than water, it is a grinding mixture of water and sharp rock particles, which can tear the traditional transportation systems. This coarse compound is like industrial sandpaper, scraping the pipe walls every second. Ordinary Steel Pipe often succumbs to wear-through within months, triggering costly production shutdowns, environmental hazards from leaks, and soaring maintenance budgets. For mining operations, where uninterrupted slurry hydro transport is critical to productivity, the choice of steel pipe and its wall thickness is not just a technical detail—it is a decisive factor in operational sustainability. This article explores how proper material selection and wall thickness design can drastically extend pipeline lifespan, with a focus on why LSAW Pipe stands out as the optimal solution for mining’s toughest conditions.

The Science of Wear: Abrasion vs. Erosion

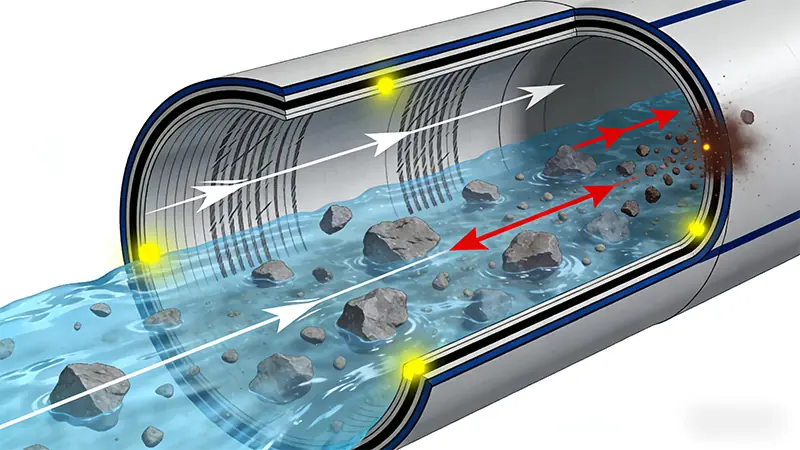

In order to understand why wall thickness is very important to the mine steel pipe, it is necessary to distinguish two main wear mechanisms that affect slurry transportation: sliding wear and impact wear. Both processes accelerate material loss, but their mechanics differ, and both are amplified in high-velocity mining environments.

When sharp slurry particles slide along the inner surface of the steel pipe, sliding wear will occur, which will produce micro-cutting effect and gradually make the steel pipe wall thinner. This situation is most common in straight pipe sections with relatively laminar flow. In contrast, impact wear is dominant at elbows, tees and other directions. In these places, particles suddenly change their trajectory and collide with the pipe wall with greater force. Research published in the journal Petroleum Science confirms that the maximum erosion angle of pipeline elbows (R = 1.5 D) is 55°, where particle impact will lead to the most serious pipe wall damage and perforation risk.

Both types of wear have a key principle: wear rate increases exponentially with flow rate. Even if the slurry speed is moderately increased, the wall thinning speed can be doubled or tripled, so that thick-walled steel pipes become a necessary buffer to prevent accelerated deterioration. This is particularly relevant for mining applications, where high speed is usually required to prevent particle sedimentation and maintain effective tailings discharge.

Why is carbon steel still king?

When choosing the pipeline for transporting mining slurry, the debate usually focuses on carbon steel pipeline and HDPE (High Density Polyethylene). While HDPE offers cost advantages and corrosion resistance, it falls short in the harsh conditions of mining operations—making carbon Steel Pipe the undisputed choice for high-pressure, long-distance applications.

HDPE pipes is light in weight and low in price, but its rigidity is low, which requires dense supporting structures, increases the installation costs and limits the span. More importantly, HDPE can not withstand the high pressures common in mining slurry hydro transport, where system pressures often exceed 10 MPa. In contrast, carbon steel pipes have extraordinary rigidity, allowing a larger spans between supports and reducing the cost of infrastructure. Its high tensile strength (more than 415 MPa for API 5L grades, such as B and X42) has passed the verification of industry material specifications, making it able to handle extreme pressures, making it the only feasible choice for long-distance slurry pipeline and tailings discharge systems.

In addition, carbon steel pipe can be made to meet strict industrial standards such as ASTM A53 and API 5L, ensuring consistent performance in wear environment. For example, ASTM A53 pipeline is designed for fluid transportation with reliable mechanical properties, while API 5L grades (such as X42, X52 and x 70) provide enhanced strength and toughness, which are tailored for energy and mining applications. These standards ensure that carbon steel pipe can withstand the mechanical stress and wear of mining operations, unlike HDPE, which will degrade quickly under repeated impact.

Common Mining Pipe Materials Comparison Table

| Material | Pressure level | Abrasion Resistance | Cost (market average in 2025) |

| Standard steel pipe (ASTM A53) | High (up to 15 MPa) | Good | $1,900–$2,400 per ton |

| Thick-walled steel pipe (API 5L X52) | Very high (up to 30 MPa) | Excellent | $5,800–$6,200 per ton |

| High-density polyethylene | Low (up to 2 Mpa) | Moderate | $1,200–$1,800 per ton |

The Allland Solution: Heavy Wall LSAW Pipe

Since wear is inevitable in mining slurry transport, the most effective strategy to extend Steel Pipe lifespan is to incorporate sacrificial wall thickness. This “wear allowance” acts as a physical barrier to prevent wear, and even if the inner surface becomes thinner over time, it can ensure the pipeline to maintain a good structure. For general applications, the corrosion allowance of standard steel pipes is usually 3-6 mm, while the wear allowance of more than 10 mm is needed in mining environment to withstand continuous particle impact.

Allland’s heavy wall LSAW Pipe is engineered specifically to meet this need. In mining application, longitudinal submerged arc welded pipe (longitudinal submerged arc welded pipe) has obvious advantages over SSAW pipe (spiral submerged arc welded pipe). The spiral weld of SSAW pipe produces internal bulge, which disturbs slurry flow, produces turbulence and accelerating local wear, especially at the weld. In contrast, LSAW Pipe features a smooth inner surface with a single longitudinal weld, minimizing flow resistance and eliminating turbulence hotspots. This design ensures uniform wear across the pipe wall and maximizes the effect of sacrificing thickness.

Another main advantage of longitudinal submerged arc welding pipe is its ability to adapt to extreme wall thickness-up to 30 mm+-which far exceeds the ability of SSAW or seamless steel pipe. This thick-walled structure is combined with API 5L PSL 2 standards, which has excellent durability. Allland’s LSAW Pipe is available in API 5L grades X42 to x 70, with outer diameter (OD) ranging from 219 mm to 762 mm and customizable wall thicknesses to match specific mining needs, aligned with API 5L dimensional specifications. The pipes undergo rigorous non-destructive testing, including ultrasonic flaw detection and hydrostatic pressure testing, to ensure no structural defects that could compromise wear resistance.

For mining operations, the reliability of LSAW Pipe translates to lower total cost of ownership (TCO). While heavy wall LSAW Pipe has a higher upfront cost than standard steel pipe, it eliminates the frequent replacements, downtime, and environmental risks associated with thinner-walled alternatives. A single heavy wall LSAW Pipe can last 5–8 times longer than a standard steel pipe in slurry applications, drastically reducing long-term costs.

FAQ

Q 1: What’s the difference between ASTM A53 and API 5L steel pipes for mining?

A: ASTM A53 is a general fluid transport standard, which is suitable for low-pressure to medium-pressure mining applications. API 5L is a specialized standard for pipeline steel, offering higher strength grades (X42–X70) with enhanced toughness and wear resistance—ideal for high-pressure slurry hydro transport and tailings discharge. Due to the excellent performance of API 5L in wear environment, Allland recommends using API 5L for mining.

Q 2: How does wall thickness affect the service life of steel pipe for mining?

A: The wall thickness is directly related to the service life, because it provides a sacrificial layer that is resistant to wear. In high-wear mining applications, the service life can be extended by 6-12 months for every millimeter of wall thickness increase. In terms of slurry transportation, the performance of 30mm+ thick-walled longitudinal submerged arc welded pipe of Allland is usually 3-5 times higher than that of standard steel pipe of 10 mm-15 mm..

Q 3: Can LSAW Pipe be customized for specific mining conditions?

A: Yes. Allland offers customizable LSAW Pipe with wall thicknesses from 10 mm to 30 mm+, API 5L grade options, and 3PE anti-corrosion coatings for enhanced corrosion resistance. We tailor each pipe according to the slurry composition, flow rate and pressure requirements of the mine to optimize wear resistance.

Conclusion

When selecting steel pipes for slurry transportation, mining operations can not put upfront cost above long-term reliability. The harsh reality of abrasive slurry demands a solution that addresses wear at its core—and that solution is heavy wall LSAW Pipe. By adding a large amount of wear allowance, taking advantage of the smooth flow characteristics of longitudinal submerged arc welded pipes and complying with strict ASTM A53 and API 5L standards, Allland steel pipes minimize downtime, reduce maintenance costs and reduce environmental risk.

The true value of heavy wall LSAW Pipe lies in its ability to reduce total cost of ownership. Although the initial purchase costs is high, with the passage of time, the extended service life and reduced replacement frequency will bring significant savings. For mining operations seeking to maximize productivity and sustainability, there is no better choice than purpose-engineered heavy wall LSAW Pipe.Tired of replacing worn-out pipes? Contact Allland for heavy wall LSAW Pipe designed specifically for mining slurry applications—where durability meets performance.

Share:

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.

Related Articles

ASTM A53 vs. API 5L: A Guide to Selection and Application

Introduction:Technology differences determine success or failure, and selection needs to be “precise”

Steel Density Analysis: Core Differences between Mild and Medium Carbon Steels and Industrial Applications

3LPE coated steel pipe: a solid barrier in the field of industrial corrosion protection

3LPP coated pipe: anti-corrosion guard in high temperature and high pressure environment

FBE steel pipe: the technological armor of the steel defense line

HOT TAGS

latest posts

- How LSAW/SSAW Steel Pipes Ensure Safe & Durable Drinking Water Pipelines

- LSAW steel pipe vs ERW steel pipe: Unveiling Core Process Differences in Steel Pipe Welding from Arc to Current

- The Essential Guide to High Pressure Pipe Applications

- API 5L Grades Explained: X52, X65 & X70 Meaning?

- A Guide to Offshore Steel Pipe & Tubes for Subsea Projects