China LSAW Manufacturer & Welded Pipe Supplier | Allland

Are you searching for a reliable China LSAW manufacturer? Are you sourcing LSAW steel pipe of exceptional quality for a critical project?

Feel free to consult Allland, one of the best China LSAW pipe manufacturers and the welded pipe supplier that could provide the most services. Here you get not just best LSAW Pipes but overall Project Solutions. From our SSAW STEEL PIPE for water and oil systems and PILING PIPE for foundations to pipe fittings and accessories, you will find what you need!

China LSAW Steel Pipe Supply

LSAW stands for Longitudinal Submerged Arc Welded.The product since more than 30 years is part of the modern steel pipe industry along with SSAW steel pipe and seamless pipe and is a key category in the pipe industry.

The core technology of LSAW pipe lies in its production from discrete steel plates, which are formed and then joined with a straight, longitudinal weld seam. This manufacturing process produces LSAW steel pipes primarily designed for long-distance transportation and large-diameter pipelines, such as ONSHORE PIPELINE and OFFSHORE PIPELINE systems.

Allland offers an extensive range of LSAW pipe dimensions:

· Outer Diameter: Φ406.4mm ~ Φ1524mm (16″ – 60″)

· Wall Thickness: 6mm ~ 60mm

· Length: 3m ~ 12.5m (Standard single length)

Custom dimensions are available based on project requirements, with wall thicknesses up to 60mm possible through our JCOE process. You’re sure to find the perfect size!

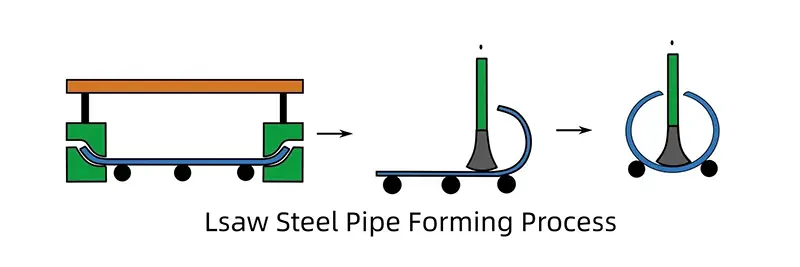

LSAW Pipe Manufacturing Process

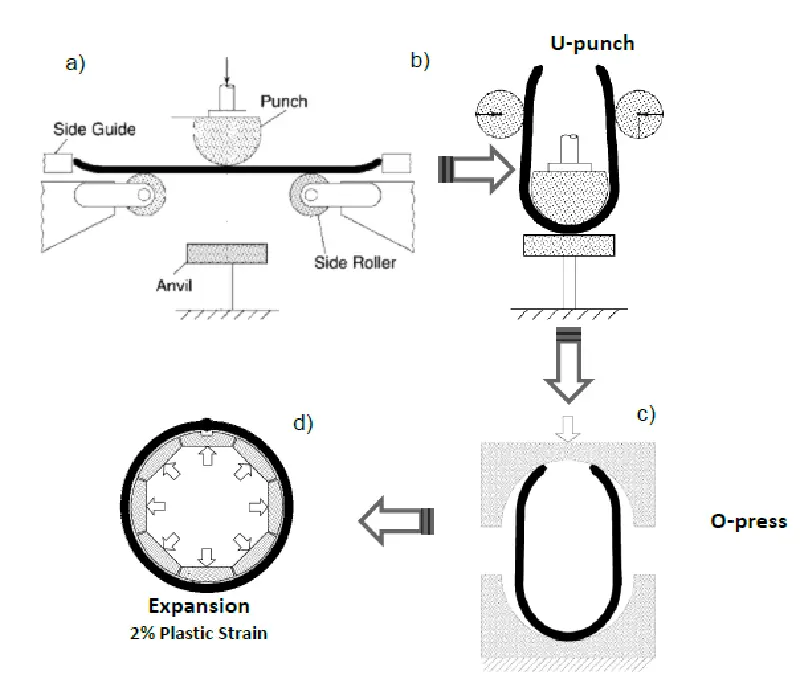

Allland is a leading China LSAW pipe manufacturer, we have advanced and completed production lines for UOE and JCOE production manufacturing.While both processes use Double Submerged Arc Welding (DSAW) and Mechanical Expanding to have the finished pipe, their forming methods are different and offers different benefits you, the buyer.

| Key Aspect | JCOE Process (Flexible Bending) | UOE Process (Stamping Forming) |

| 1. Forming Principle | Progressive Press Bending: The steel plate is gradually pressed into shape through multiple steps: J-forming → C-forming → O-forming to close the seam. | Stamping Forming: The plate is formed in two powerful strokes: first into a U-shape by a U-die, then into an O-shape by an O-die. |

| 2. Core Equipment | CNC Step-by-Step Press | Large, high-tonnage U-ing Press and O-ing Press. |

| 3. Forming Characteristics | Flexible, gentle forming process. High precision and control, resulting in low internal stress. | Massive forming force. Highly efficient with excellent overall roundness and dimensional consistency. |

| 4. Best Use Case | Ideal for multiple specifications, non-standard diameters, and small-batch orders. | Ideal for high-volume, mass production of a single, standardized specification. |

| 5. Product Advantage | Wider product adaptability. The best choice for very thick-walled (up to 60mm+), high-grade steel pipes. | Better efficiency for mass production. Delivers superior quality and consistency for large, standard pipe orders. |

| 6. Subsequent Process | Both require Mechanical Expanding to relieve stress and precisely shape the pipe. | Both require Mechanical Expanding to relieve stress and precisely shape the pipe. |

Value-Added Services

The thing is that a bare LSAW pipe is hardly the end product. Our welded pipe production at Allland extends beyond the manufacturing line with a full range of value added services, transforming a simple basic pipe into a solution a ready project.

· Anti-Corrosion Coatings: We operate our own advanced coating facilities to produce FBE STEEL PIPE, 3LPE STEEL PIPE, and 3LPP STEEL PIPE.

FBE (Fusion Bonded Epoxy): Basic anti-corrosion coating with good adhesion, suited as internal lining for DRINK WATER PIPELINE systems or as external coating layer without lining.

3LPE (Three-Layer Polyethylene): High performance system for the most demanding buried pipelines.It is composed of an FBE primer, an adhesive layer and a polyethylene outer layer which provides excellent mechanical protection and insulation.

3LPP (Three-Layer Polypropylene): Ideal for HIGH PRESSURE PIPE or offshore applications where higher service temperatures are required.

· Pipe Processing: Allland offers the full range of processing options to meet your specific needs, such as precision cut-to-length, weld beveling (chamfering), and threading, resulting in efficient and precise field jointing.

· Fittings and Couplings: And to top off your solution, we also provide all corresponding Pipe Fittings and Grooved Fittings & Couplings, for a perfect 100% match, and so you don’t have to buy from multiple suppliers.

LSAW Pipe Quality, Standards, and Applications

Quality Control and Standards

Allland, as a distinguished China LSAW pipe manufacturer, We provide LSAW pipes conform with international standards such as API 5L PSL1/PSL2, ISO 3183-3 and supply different grade from L245 to X80.

Our quality control process is rigorous and transparent:

1. Material Control: Rigorous inspection of all incoming raw steel plates.

2. Visual Inspection: 100% surface examination of all pipes and weld joints.

3. Weld Inspection (NDT): We perform complete NDT, with UT fast scan and slow scan, RT, and MT to verify a perfect weld.

4. Physical Property Testing: We perform tensile, impact and other physical tests to verify that the mechanical properties of the pipe conform to the standard.

5. Hydrostatic Testing: Each pipe is hydrostatically tested to ensure its strength and leak tightness.

We also welcome third-party inspection services (such as SGS, BV, TUV) to guarantee the highest quality of the pipes you receive.

Advantages & Applications of LSAW Pipe

The LSAW process has a distinct advantages in the product, such as stable and uniform welding quality, good weld seam profile with low flow resistance, high production efficiency. This makes it the perfect selection for severe large diameter service:

·!– /wp:paragraph –>

· Structural Engineering: Heavy-duty supports for bridges, large buildings, and port facilities. This is our STRUCTURAL PIPE and PILING PIPE line.

· Water Supply and Drainage: Critical urban water supply networks and sewage treatment pipelines, including DRINK WATER PIPELINE systems (when internally lined).

· Specialty Applications: We also manufacture LSAW for specialty industrial uses, such as FLOATING PIPE for dredging and SHOULDER PIPE.

FAQ

Q1: What is the main difference between LSAW and SSAW pipe?

A1: The blast seam is the only difference. LSAW STEEL PIPE: It has one straight (lengthwise) seam, which makes it the best option for high-pressure and critical service ONSHORE PIPELINE systems.SSAW STEEL PIPE: It has a helical (spiral) seam; this is a cheaper production method for larger diameter pipes for low and medium pressure applications such as water supply.

Q2: Why would I choose the JCOE process for my LSAW pipe?

A2: The JCOE procedure lends itself perfectly to flexibility. You would select this if your project needs non-standard diameters, unusually thick walls (e.g. above 50mm), or small batch volumes.A UOE line is designed for large volume mass production and is not very suitable for these custom orders.

Q3: What are 3LPE STEEL PIPE and FBE STEEL PIPE?

A3: These are not pipe products but rather high quality, high performance anti-corrosion coatings for steel pipes. FBE STEEL PIPE has a Fusion Bonded Epoxy coating which is good for the internal lining (used for DRINK WATER PIPELINE) or as a base coat.3LPE STEEL PIPE utilizes two additional layers to provide the highest level of mechanical and under ground protection, which is why it is the preferred solution for buried ONSHORE PIPELINE applications.

Contact Allland Today!

After reading this guide, you should have a solid understanding of LSAW steel pipes. If you need to purchase LSAW steel pipe, trusting Allland is absolutely the right choice!

Here, you not only get steel pipes meticulously crafted with care but also receive a highly detailed, tailor-made solution from a complete welded pipe supply partner.

If you wish to purchase LSAW steel pipes, contact us immediately by clicking “Request a Quote”!

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.

Related Articles

ASTM A53 vs. API 5L: A Guide to Selection and Application

Introduction:Technology differences determine success or failure, and selection needs to be “precise”

Steel Density Analysis: Core Differences between Mild and Medium Carbon Steels and Industrial Applications

3LPE coated steel pipe: a solid barrier in the field of industrial corrosion protection

3LPP coated pipe: anti-corrosion guard in high temperature and high pressure environment

FBE steel pipe: the technological armor of the steel defense line

HOT TAGS

latest posts

- Introduction:Technology differences determine success or failure, and selection needs to be “precise”

- FBE Steel Pipes: Corrosion Protection Redefined

- DIN 30671: A Guide to FBE Coating for Steel Pipes

- A Guide to Structural Pipe: ASTM A500vsEN10219

- Weld Seam Integrity: A Deep Dive into LSAW vs. SSAW Pipe