Why Steel Pipe is Best for Fluid Conveyance Systems

Introduction

When designing a project for either fluid conveyance or a large structural build, engineers and project managers have a pivotal material decision to make. Do they go with polymer products such as HDPE, or the tried and true reliability of steel pipe? The “steel pipe” itself is huge, from ASTM A500 structural hollow sections to high pressure API 5L transmission pipes.

Though the new plastics have an enticing low up front cost, the real success factor is life cycle value performance, safety, and TCO. And in this respect, the engineering benefits of steel pipe in all its forms can simply be matched by no other product.

In this article, the fundamental characteristics of steel pipe will be examined in a side-by-side comparison with the leading alternatives to show why steel is still the optimal design solution for meeting stringent performance, safety, and cost of ownership criteria.

The Core Engineering Attributes of Steel Pipe

Selecting steel pipe is not just a matter of choosing a material, it is choosing an engineering solution based on its physical properties.

1. Superior Strength and Toughness

Strength and toughness is the best description to summarise steel pipe. It has the capacity to resist both high internal pressure and extreme outside loads.

Allland Insight: That toughness is a design essential. For fluid systems, it means the pipe can take dynamic loads such as water hammer, settlement, and vibration.This same strength is seen in structural applications where the ASTM A500 hollow section offers a higher, dependable load carrying capability for plant and buildings when compared to other structural hollow sections.

2. Life-Cycle Reliability

Steel is a very stable subject and its mechanical and technological properties are stable in time. It provides a constant high safety factor even in the presence of cyclic fluctuations in the tensile stress conditions.

Allland Insight: This is quite different when it comes to polymer materials. The mechanical properties of HDPE and PVC may be subject to time-dependent decays. In addition, the steel is not so susceptible to temperature changes, which is an important benefit and during storage and installation.

3. Unmatched Installation Flexibility and Efficiency

Steel tubing offers great versatility for field work. It is easily cut and welded in the field and can be adapted to all types of terrain and can be bent and fitted in the field.

In addition, steel pipes can be served in different lengths. This is even more the case for large diameter line pipe (LAP), where LSAW steel pipe and SSAW steel pipe to API 5L can be supplied in long, tailored lengths (e.g. 12 meters to 13.5 meters or more).This feature optimizes the job expenditure:

· In urban settings: Shorter pipes can be used to navigate existing complex underground utilities.

· In rural areas: Longer lengths, typical of LSAW steel pipe, reduce the number of joints, which lowers material and labor costs and also minimizes potential leak points.

4. Critical Health & Safety

This is a key area where steel provides a superior, multi-faceted solution.

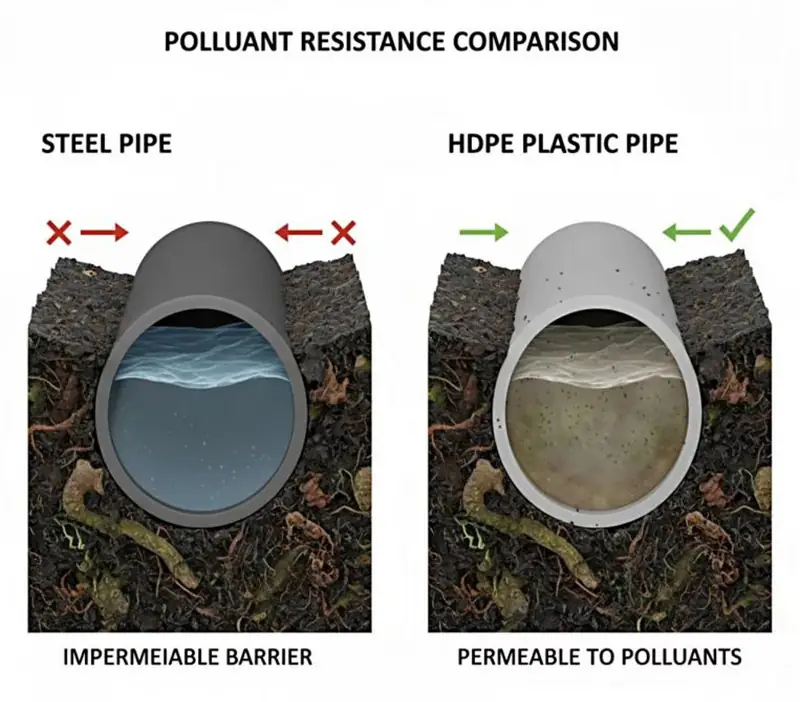

Protection from outside elements (Impermeability): Steel is all impermeable. This is a crucial safety feature of the. Polymer (HDPE/PVC) pipes can be permeable, and external contaminants (such as hydrocarbons, pesticides, or solvents in the soil) may have the chance to enter the pipe and affect water quality. Steel removes that risk completely.

Internal Protection (Lining): full rust would occur if you were transporting potable water in bare carbon steel. That’s why advanced internal linings are employed in the modern steel pipe system. For drinking water, a food grade FBE (Fusion Bonded Epoxy) lining is coated on the inside of the pipe. This lining separates the steel from the water so you get no rust and no leaching of anything into your fluid.

Equipped with a non-permeable steel wall on the outside and a layer of inert FBE coating on the inside, this double-layer system provides a safety and water quality guarantee which cannot be attained with any single layer material.

Allland Guide: A Quantitative Comparison vs. Alternative Materials

To help you make an informed decision, we created this clear comparison table summarizing the key advantages of steel pipe over other materials, based on the original article’s analysis.

| Material Compared | Core Advantage of Steel Pipe | Allland‘s Bottom Line (Why Steel Wins) |

| Cast Iron | • Lighter and cheaper per unit weight.• Steel fittings have lower costs and shorter production times, especially for large diameters.• Typically does not require concrete anchoring blocks. | Lower Total Project Cost and Faster Installation. The savings from eliminating anchoring systems are significant. |

| Polymer (HDPE / PVC) | • Mechanical properties do not suffer from progressive deterioration.• Less sensitive to temperature fluctuations.• Completely impermeable: does not release substances into the fluid or allow external contaminants to enter. | Superior Long-Term Safety and Water Quality. For potable water or critical industrial fluids, the stability and impermeability of steel are irreplaceable. |

| Cement Materials | • Superior mechanical and hydraulic characteristics.• Better sensitivity to dynamic loads.• Perfect joint sealing and impermeability.• Non-brittle material: eliminates downtime from breakages during handling and installation. | Higher Operational Performance and Lower Installation Waste. Steel’s toughness means less product is wasted due to breakage during transport and installation, saving time and money. |

Conclusion

To sum it up, steel tube – from the structural ASTM A500 square and rectangular shape, to the heavy-duty API 5L line pipe — provides a unique balance of strength, toughness, long term reliability, and safety that no other material can promise. At Allland, we know good material is just the beginning, which is why we make the promises that each and every pipe we deliver has been able to stand up to an advanced manufacturing technology and the most stringent quality controls in the pipe industry. Engineering professionals realize that choosing steel pipe is a prudent engineering choice; you simply need to make the decision to Allland to provide the business case for why your project will succeed. Planning your materials for your next project? Get in touch with our experts and let us tailor the right solution to your needs: technically superior and cost-effective.

FAQ

Q1: Aren’t steel pipes much more expensive than PVC or HDPE pipes?

A1: Distinguishing between initial purchase price and total cost of ownership is very important. Despite the fact that polymers such as PVC or HDPE could be less expensive in the beginning as material cost, steel is more economical in the end for the duration of the project. Due to the greater strength of steel, engineers are often able to use a smaller diameter pipe or a pipe with thinner walls and still achieve the same pressure rating, resulting in less material. Moreover, the longer life of steel and its insensitivity to mechanical property deterioration provide for a longer and more reliable service life with lower replacement costs.

Q2: What about corrosion? Don’t polymer pipes last longer because they don’t rust?

A2: This is an engineering challenge that has been fully addressed. Steel pipe today is a finished product. Externally, advanced coatings such as 3LPE (Three-Layer Polyethylene) or 3LPP offer an impermeable barrier to soil and water for more than 50 years.Internally, for potable water applications, a food-grade FBE (Fusion Bonded Epoxy) lining is used, which fully isolates the fluid from the steel and eliminates the potential for internal corrosion or rust.

Q3: For a large-diameter water transmission line, is SSAW steel pipe a better choice than HDPE?

A3: SSAW steel pipe is a natural choice for critical large diameter water mains. For one is Safety: SSAW pipe is sealed, assuring that any ground contaminates such as hydrocarbons or pesticides cannot be introduced into the water supply, a risk for HDPE. Secondly, it provides you with the assurance that with an internal FBE coating the pipe will not corrode on the inside and with an FBE coating on the outside as well only clean water will run through your pipe.This double layer of protection system outperforms polymer solutions.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.

Related Articles

ASTM A53 vs. API 5L: A Guide to Selection and Application

Introduction:Technology differences determine success or failure, and selection needs to be “precise”

Steel Density Analysis: Core Differences between Mild and Medium Carbon Steels and Industrial Applications

3LPE coated steel pipe: a solid barrier in the field of industrial corrosion protection

3LPP coated pipe: anti-corrosion guard in high temperature and high pressure environment

FBE steel pipe: the technological armor of the steel defense line

HOT TAGS

latest posts

- Introduction:Technology differences determine success or failure, and selection needs to be “precise”

- FBE Steel Pipes: Corrosion Protection Redefined

- DIN 30671: A Guide to FBE Coating for Steel Pipes

- A Guide to Structural Pipe: ASTM A500vsEN10219

- Weld Seam Integrity: A Deep Dive into LSAW vs. SSAW Pipe