How to Get a Fast & Accurate Steel Pipe Quotation

In international trade of steel pipes and project procurement, the speed and accuracy of quotations often directly affect the decision-making efficiency. A clear and complete inquiry form is the key for us to provide you with accurate quotations in the shortest time. Only when we obtain comprehensive information can we quickly calculate the cost of raw materials, production processes, transportation costs and the corresponding delivery cycle. This article will start from five key dimensions to help you understand how to prepare an efficient inquiry form, so that you can obtain the most competitive steel pipe quotations in the shortest time.

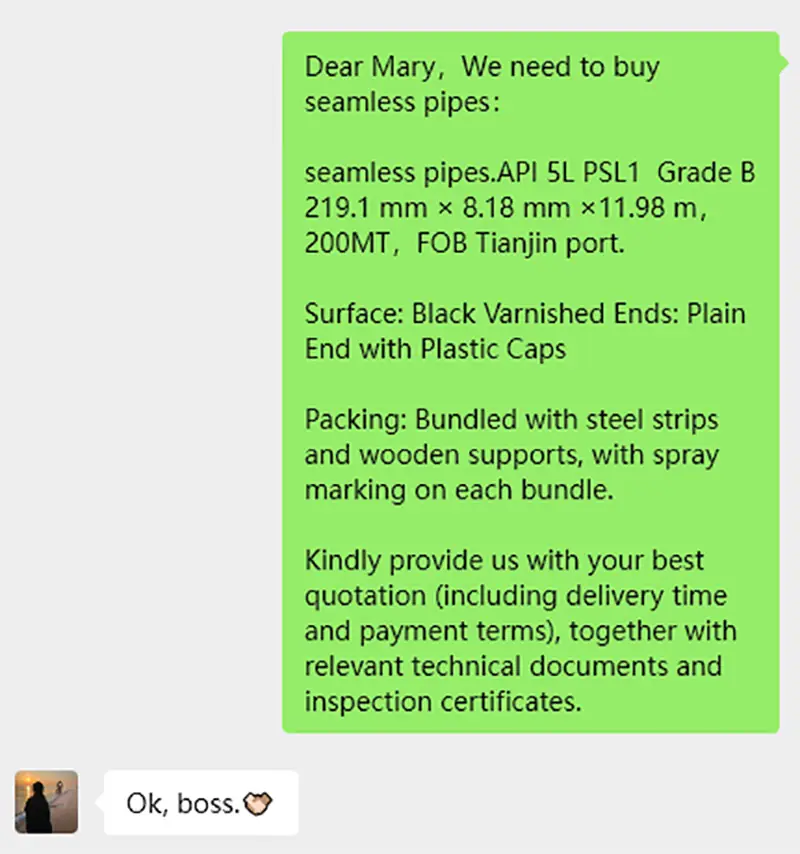

Point 1: Accurate Pipe Specifications

The three core parameters of steel pipes are: outer diameter, wall thickness, and length.These three data determine the weight of the steel pipe and directly affect the material cost and processing technology.

For example, a steel pipe with an outer diameter of 219mm × wall thickness of 8mm × length of 12m may differ by hundreds of kilograms in weight from a steel pipe with an outer diameter of 273mm × wall thickness of 10mm.

The cutting and transportation costs of the same steel pipe will also vary at different lengths.Therefore, please be sure to specify the precise OD × WT × Length parameters in the inquiry form. This way, the sales engineer can immediately calculate the weight and accurately calculate the unit price and total price.

Point 2: Clear Standards and Grades

Steel pipes are not merely “tubes”. They must comply with international or industry standards. Common ones include:

API 5L: such as Grade B, X42, X52, X70.

ASTM A106 / A53: such as Grade A, Grade B, Grade C.

EN 10219 / EN 10210 : such as S235JRH, S275J2H, S355J2H, S420, S460.

GB/T : such as Q235, Q345, 20#, L245—L450.

Different standards and grades directly affect the chemical composition, mechanical properties, and production processes of steel pipes.

For instance, the yield strength of API 5L Grade B is around 245 MPa, while that of API 5L X70 can reach over 485 MPa, and their prices naturally differ. Even for seamless steel pipes, if the standard requirement is ASTM A106 Gr.B, it is different from EN 10216-2 P265GH in terms of composition and performance requirements, and the final unit price will also have a significant difference. Therefore, please clearly specify the standard and grade when making inquiries to avoid ambiguous descriptions. Only in this way can we provide materials that fully meet your project requirements, rather than just offering a “reference price”.

Point 3: Clear Quantity Requirements

Quantity is another key factor affecting the price. If the customer only needs a few dozen steel pipes, the production plan may need to be arranged as “small-batch customization”, with a relatively higher unit price.

If the order quantity reaches a full container load (FCL) or several thousand tons, we can arrange large-scale production to reduce unit costs and thus offer more competitive prices.

Quantity also directly affects transportation and container loading plans:

A 20-foot container can usually load 25-27 tons of steel pipes.

A 40-foot high cube container can load 26-28 tons.

Too small a quantity will result in relatively higher transportation costs and affect the progress of procurement.

Therefore, in the inquiry form, please specify your requirements as much as possible in terms of tonnage (MT) or total length (m).

Example: “Need 200 tons of API 5L X52 PSL1 pipeline steel pipes, OD 323.9mm, WT 9.5mm, length 12m, with end port protection caps on each piece.”

In this way, we can immediately match the inventory or formulate a reasonable production and container loading plan.

Point 4: Detailed Surface Treatment and Packaging Requirements

The surface treatment and coating of steel pipes can significantly affect the price and delivery time. Common options include:

Black paint: A basic anti-rust coating, suitable for short-term storage and ordinary transportation.

Hot-dip galvanizing: Enhances corrosion resistance and is often used for outdoor or water pipe systems.

Anti-corrosion coating: Widely used in oil and gas transmission projects, effectively extending the service life.

Bare pipe: No coating required, but stronger anti-rust measures are needed during transportation and storage.

Different surface treatment methods require different production processes and cycles.

For example, black-painted steel pipes can be produced within a few days.

3PE-coated steel pipes, however, require additional coating workshops and inspection procedures, which may extend the delivery time by 2 to 3 weeks.

Packaging details include: bundling methods, wrapping with plastic sheeting or waterproof film, port protection, marking, and port end finishing or chamfering.

Therefore, if you do not specify surface treatment and packaging details in your inquiry, the supplier can only quote the “bare pipe price”, which may cause repeated modifications in the subsequent confirmation process, wasting valuable time.

Point 5: Specific Delivery Location

In international trade, common quotation terms include:

EXW: Ex-works price

FOB: Free on Board, which only includes the price at the port of shipment.

CIF: Cost, Insurance and Freight, which includes freight and insurance.

If you would like us to quote CIF prices directly, you must provide the destination port information.

For example, the freight and insurance to Bangkok Port in Southeast Asia are relatively low.

However, if it is to Port of Santos in South America, the freight could be 3 to 5 times higher.

Only by clarifying the destination port can we immediately contact the shipping company, obtain the latest freight rates, and include them in the total quotation.

Conclusion – Get a Quote Now with the Right Information

To quickly receive an accurate quote for steel pipes, your inquiry must include the following five key points:

1. Accurate pipe specifications (OD × WT × Length)

2. Clear standards and grades (Standard & Grade)

3. Clear quantity requirements (in tons or meters)

4. Detailed surface treatment and packaging requirements

5. Specific delivery address

Now that you have all the key information, please send your inquiry to our dedicated email or submit it through the inquiry form on our official website. As long as the information is complete, our sales engineers will provide you with a competitive and fully project-compliant formal quote within 24 hours!

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.

Related Articles

ASTM A53 vs. API 5L: A Guide to Selection and Application

Introduction:Technology differences determine success or failure, and selection needs to be “precise”

Steel Density Analysis: Core Differences between Mild and Medium Carbon Steels and Industrial Applications

3LPE coated steel pipe: a solid barrier in the field of industrial corrosion protection

3LPP coated pipe: anti-corrosion guard in high temperature and high pressure environment

FBE steel pipe: the technological armor of the steel defense line

HOT TAGS

latest posts

- 3LPP coated pipe: anti-corrosion guard in high temperature and high pressure environment

- ASTM A53 LSAW Steel Pipe Selection Guide for Oil and Gas Transportation Pipelines

- API 5L LSAW Pipe: A Deep Dive into PSL1 vs. PSL2

- Steel Pipe Sizing Errors? DN vs. OD Explained for Buyers

- NDT for Pipe Welds: X-ray vs. Ultrasonic Testing