SCH 40 vs. SCH 40S: Wall Thickness Guide

Introduction

You are a project engineer or a procurement manager and you are looking at a P&ID (Piping and Instrument and Control Diagram) for a project on the horizon. You have two different pipe callouts: 4-inch SCH 40 A53 for a carbon steel utility line and 4-inch SCH 40S 304L for a stainless steel process line. That’s where the confusion begins. Is the “S” on the stainless pipe indicating that it is special, or that it is thinner-wall? Can I use them interchangeably in my hydraulic or structural calculations? And what about larger sizes, like NPS 10” or 12”?

It’s not just a theoretical question. Misjudging these pipes as dissimilar – or misjudging all stainless pipe as being thinner – can cause disastrous engineering decisions. Such as erroneous estimation of pressure drop, weight for structural support, and project cost-in-analysis.

This is a multi-million dollar question, and the answer may surprise many. So let’s get straight to the point: Yes, according to all tables and charts, their wall thickness are exactly the same for every commonly specified size! This guide is going to tell you exactly why they are equal, give you the data right from the governing standards, and most importantly, why the rumor of “thinner stainless pipe” is so common and where it originated from.

The Standards Behind the Labels

The confusion is born from the fact that these two pipe schedules are defined in two different (but related) standards.

· What is SCH 40? The “Schedule 40” rating for carbon and alloy steel pipe has a hoop strength described in ASME B36.10M, “Welded and Seamless Wrought Steel Pipe”. This is the base standard for typical pipe materials such as ASTM A53, ASTM A106 and API 5L. It specifies the standard wall thickness for the given Nominal Pipe Size (NPS).

· What is SCH 40S? The coverage of the ”Schedule 40S” title complies with the ASME B36.19M – “Stainless Steel Pipe”. This standard was written particularly for stainless steel materials such as 304L and 316L.

· What Does the “S” Mean? The “S” at the end just denotes that the schedule is part of the stainless steel series (B36.19M). It doesn’t stand for “special” or “slimmer”. The main purpose for the separate B36.19M standards was to define new economical thin walled schedules for stainless steel which are not available for carbon steel like SCH 5S and SCH 10S.It is these other “S” schedules that start to confuse the issue.

The Core Evidence

The surest way to get an end to the argument is to go straight to the source (the standards) and look at the data. The ASME B36.19M (Stainless) standard was developed to be consistent with the B36.10M (Carbon) standard for all schedules available.

The following table compares the nominal wall thickness for SCH 40 and SCH 40S across a range of common sizes.

| Nominal Pipe Size (NPS) | SCH 40 Wall Thickness (ASME B36.10M) | SCH 40S Wall Thickness (ASME B36.19M) | Do They Match? |

| 4-inch | 0.237 in (6.02 mm) | 0.237 in (6.02 mm) | Yes |

| 6-inch | 0.280 in (7.11 mm) | 0.280 in (7.11 mm) | Yes |

| 8-inch | 0.322 in (8.18 mm) | 0.322 in (8.18 mm) | Yes |

| 10-inch | 0.365 in (9.27 mm) | 0.365 in (9.27 mm) | Yes |

| 12-inch | 0.406 in (10.31 mm) | 0.406 in (10.31 mm) | Yes |

Observation and Conclusion: ASME standards information is clear and unequivocal.From NPS 1/8-inch to NPS 12-inch (including), the nominal wall thickness of SCH 40 and SCH 40S is exactly the same.

Debunking the Myth

If the data is so clear, why does this pervasive myth exist? This is the most valuable part of the guide, as the myth is born from a correct engineering principle that is incorrectly applied.

The confusion comes from mistaking SCH 40S with SCH 10S.

Here is the real-world engineering logic:

1. Superior Strength: The allowable stress (strength) of stainless steel (e.g., 304L) is significantly greater than that of regular carbon steel (e.g., A53 Grade B).

2. Value Engineering: Since it is stronger, an engineer could use a much thinner-walled stainless steel pipe when designing a medium pressure system to achieve the same pressure rating as a thicker-walled carbon steel pipe, and still be assured of safety..

3. The Common (Correct) Substitution: One of the most frequent “apples to apples” cost saving substitutions in the industry is to use SCH 10S stainless steel pipe instead of SCH 40 carbon steel pipe.This allows the necessary corrosion resistance and pressure rating with far less material, resulting in savings in both weight and, often, overall cost.

4. The Birth of the Myth: The truth is, over time, memory of this common replacement—”I used a thinner ‘S’ pipe to replace SCH 40″ gets garbled.Engineer and buyer recalling incorrectly that they used “SCH 40S” in place of the specified “SCH 10S” which they actually specified.

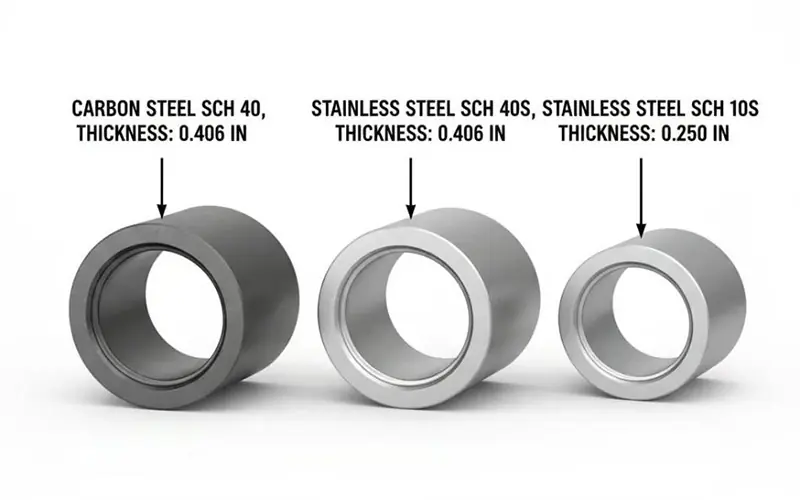

Let’s look at the real-world decision-making table:

| Engineering Scenario (NPS 12″) | SCH 40 Carbon Steel (A53) | SCH 10S Stainless Steel (304L) | SCH 40S Stainless Steel (304L) |

| Wall Thickness | 0.406 in (10.31 mm) | 0.250 in (6.35 mm) | 0.406 in (10.31 mm) |

| Relative Weight & Cost | Baseline | Significantly Lighter & Cheaper (than 40S) | Heaviest & Most Expensive |

| Common Application | Standard medium/high-pressure system. | Cost-effective replacement for SCH 40 carbon where corrosion resistance is needed. | High-pressure, high-corrosion, or heavy structural stainless steel system. |

This table clearly shows the source of the confusion. The “thinner stainless pipe” that engineers correctly remember as a cost-saving alternative is almost always SCH 10S, not SCH 40S.

Conclusion

Let’s summarize the facts into an actionable decision-making guide for all engineers, designers, and procurement managers.

Fact: Per ASME B36.10M and B36.19M, the nominal wall thickness of SCH 40 pipe and SCH 40S pipe are identical for all sizes from NPS 1/8″ through NPS 12″.

Engineering Decision Framework:

· For Carbon Steel Systems: If your project specifies carbon steel (e.g., A53, A106), your standard callout is SCH 40.

· For High-Pressure Stainless Systems: If your project specifies stainless steel (e.g., 304L) and the design calculations require the full wall thickness of Schedule 40 (e.g., 0.365″ for 10-inch pipe) due to high pressure or structural loads, you must specify SCH 40S. In this case, do not mistakenly accept the thinner SCH 10S, as it will fail your design requirements.

· For Value-Engineered Stainless Systems: If your project requires stainless steel for corrosion resistance but is a standard or medium-pressure application, do not default to SCH 40S. You should perform the pressure calculation. You will almost certainly find that the thinner, lighter, and less expensive SCH 10S is more than sufficient for your needs. This is one of the most common and effective cost-saving opportunities in piping design.

The final and most important advice is to never assume; always verify. When in doubt, do not rely on memory. Pull the official ASME B36.10M and B36.19M standard charts to confirm your wall thicknesses and ensure your design is safe, compliant, and cost-effective.

FAQ

· Q1: What about sizes larger than 12 inches (NPS 12)? I’ve heard SCH 40 and SCH 40S are different in larger sizes.

A1: This is an excellent and highly advanced question, and you are correct. This is another major source of the industry-wide confusion. For sizes NPS 14″ and larger, the dimensions for SCH 40 and SCH 40S do diverge. For example, at NPS 14″, SCH 40 (B36.10M) has a 0.438″ wall, while SCH 40S (B36.19M) has a 0.375″ wall. However, the vast majority of process piping falls within the NPS 12″ and under range, and in that entire range, they remain identical. This discrepancy in larger sizes is precisely why engineers must always verify the wall thickness for their specific size against the correct ASME standard (B36.10M for carbon, B36.19M for stainless).

· Q2: If the wall thickness is identical, does that mean a SCH 40 carbon steel pipe and a SCH 40S stainless steel pipe have the same pressure rating?

A2: No, absolutely not. That is an important engineering difference. Their physical dimensions (thickness of the wall, diameter) are equal, but their material strength (allowable stress) is completely different. Stainless steel (304L for example) ismany times stronger and has a MUCH higher allowable stress than plain carbon steel (A53 grafe B for example). So a SCH 40S stainless steel pipe will have a much higher pressure rating than a SCH 40 carbon steel pipe of the same size.

· Q3: If SCH 40 and SCH 40S are identical up to 12″, why does the “S” designation even exist for it?

A3: The “S” designation was created to group all stainless steel schedules under one standard, ASME B36.19M. The main intent of this new standard was to add the new, economically thin-walled schedules that are not available for carbon steel (such as SCH 5S, SCH 10S). In order to be consistent with this new stainless specific standard, the “S” suffix was also added to the schedules that it shared with the carbon steel standard (SCH 40S and SCH 80S), even though they have the same dimensions (up to NPS 12″).

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.

Related Articles

ASTM A53 vs. API 5L: A Guide to Selection and Application

Introduction:Technology differences determine success or failure, and selection needs to be “precise”

Steel Density Analysis: Core Differences between Mild and Medium Carbon Steels and Industrial Applications

3LPE coated steel pipe: a solid barrier in the field of industrial corrosion protection

3LPP coated pipe: anti-corrosion guard in high temperature and high pressure environment

FBE steel pipe: the technological armor of the steel defense line

HOT TAGS

latest posts

- How LSAW/SSAW Steel Pipes Ensure Safe & Durable Drinking Water Pipelines

- LSAW steel pipe vs ERW steel pipe: Unveiling Core Process Differences in Steel Pipe Welding from Arc to Current

- The Essential Guide to High Pressure Pipe Applications

- API 5L Grades Explained: X52, X65 & X70 Meaning?

- A Guide to Offshore Steel Pipe & Tubes for Subsea Projects