A Guide to ISO 21809: 3LPE & FBE Pipe Coating Standards

Steel pipes is the pillar of oil, natural gas, water supply and sewage treatment. However, the corrosion caused by moisture, chemicals substances and harsh environment will threaten their performance, life and safety. Anti-corrosion coatings is an important barrier. Among the top standards, 3LPE coating standard, ISO 21809 and FBE coating standard are the global benchmarks. In this paper, their definitions, advantages, specifications and applications are explored.

Understanding ISO 21809

ISO 21809 is more than a technical list—it’s a comprehensive international framework governing external anti-corrosion coatings for steel pipes across their entire life cycle. Split into two key parts: ISO 21809-1 (for 3 LPE/3 LPP coatings) and ISO 21809-2 (for FBE coatings), it ensures targeted regulation.

The key stages: Steel pipe surface pretreatment (sand blasting grades, cleanliness), coating material performance, application process control and final inspection. Different from the regional standards (e.g.Some SY/T standards), which are universally used, making it a “passport” for international projects. It also includes quantifiable tests, allowing manufacturers to provide tangible quality certificates to ensure consistency, no matter where the coating are manufactured or used.

3LPE coating standard(ISO 21809-1)

The 3 LPE coating standard managed by ISO 21809-1 is a widely used three-layer system, which is famous for its durability and resistance to mechanical damage. It has three layers working in harmony:

· Primer Layer: Thin fusion-bonded epoxy (FBE) applied to pre-treated steel, ensuring strong adhesion and preventing metal-coating interface corrosion.

· Adhesive Layer: Copolymer adhesive bonding the primer to the outer layer, resisting delamination.

· Polyethylene outer layer: Thick high-density polyethylene (HDPE), which can block moisture, chemicals and physical damage, and has anti-ultraviolet and anti-aging properties.

Advantages of 3 LPE coating

· Strong adhesion: According to ISO 21809-1, peel strength at 23°C exceeds 200 N/cm, and the coating remains intact under pressure or temperature changes.

· Top Corrosion Resistance: Multi-layer structure stops moisture, oxygen, and chemicals. Outer layer of HDPE can prevent water absorption, and FBE can prevent metal corrosion.

· Mechanical durability: It can withstand impact, wear and deformation without breaking (Joule value depends on thickness), and is suitable for harsh installation, such as no groove structure.

· Temperature flexibility: The standard 3 LPE treatment is up to 80°c; 3 LPP (in ISO 21809-1) reaches 110°c+, and the ambient water pipelines is installed to high-temperature oil/gas pipeline.

3 kinds of LPE technical Specifications

· Thickness: 2.2 mm (114.3 mm pipes) to 3.7 mm (≥1682.8 mm pipes) for adequate protection.

· Testing: Peeling strength, impact, cathodic peeling and thickness testing in production stage.

FBE Coating Standard (ISO 21809-2)

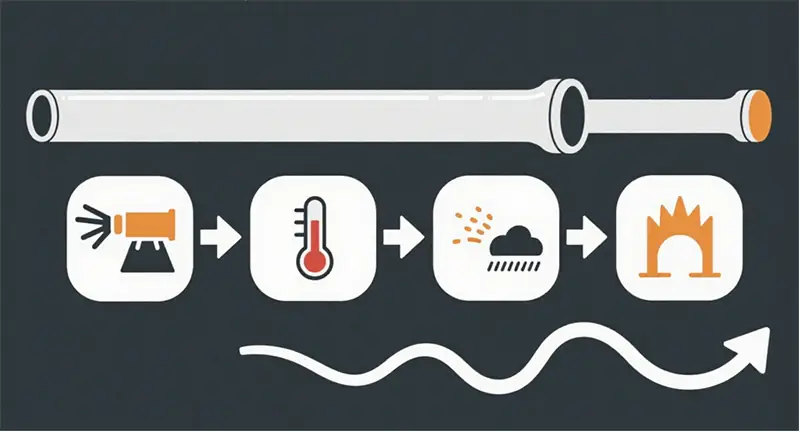

FBE coating standard (ISO 21809-2) is a single-layer fused epoxy resin system, which is an ideal choice for oil/natural gas, water and industrial pipelines. Applied as dry powder to preheated steel (200–250°C), it melts, flows, and cures into a hard film. It has two types: standard (up to 80°C) and modified (up to 120°C+), suiting diverse temps.

Advantages of FBE coating

· Superior Chemical Resistance: Withstands acids, alkalis, salts, and hydrocarbons, perfect for aggressive environments like chemical plants.

· Rapid curing: Curing in a few minutes, improving the production efficiency of large-scale projects.

· Eco-Friendly: Solvent-free, no VOCs, complying with global environmental rules.

Specification of FBE

· Surface pretreatment: Sandblasting to SA2.5 (roughness of 50-100 microns) to obtain the best adhesion.

· Curing: The temperature/time depends on powder type;

· Testing: Adhesion, impact, chemical resistance, and UV tests.

Why Choose ISO 21809-Compliant Coatings?

Over regional/outdated standards, ISO 21809-compliant 3 LPE/FBE offers key benefits:

· Total Control: Covering all production steps (from material to inspection), to prevent incomplete regional standards from causing inconsistent quality.

· Verifiable performance: Rigorous and quantifiable testing allows manufacturers to provide high-quality reports, unlike vague regional standards.

Main Applications

· Oil/Gas: 3 LPE for onshore/offshore pipelines (80°C; 3 LPP for 110°C+); FBE for well casings/subsea pipes.

· Chemical processing: FBE; of corrosive liquids; 3 LPE for less aggressive chemicals, ensuring safety.

· Power Generation: 3 LPE for moderate-temp steam pipes; FBE for indoor pipelines (easy to install)

· Infrastructure: 3 LPE is used for above/underground pipelines (UV-resistant/impact-resistant); FBE for indoor pipes (easy install).

Conclusion

ISO 21809, 3 LPE coating standard, and FBE coating standard are essential for steel pipe protection. ISO 21809 ensures global quality, 3 LPE offers multi-layer durability, and FBE provides single-layer efficiency.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.

Related Articles

ASTM A53 vs. API 5L: A Guide to Selection and Application

Introduction:Technology differences determine success or failure, and selection needs to be “precise”

Steel Density Analysis: Core Differences between Mild and Medium Carbon Steels and Industrial Applications

3LPE coated steel pipe: a solid barrier in the field of industrial corrosion protection

3LPP coated pipe: anti-corrosion guard in high temperature and high pressure environment

FBE steel pipe: the technological armor of the steel defense line

HOT TAGS

latest posts

- FBE steel pipe: the technological armor of the steel defense line

- Precision Engineering Redefined Dubai’s Stadium Dome Construction

- An Engineer’s Guide: A Deep Dive into UOE vs. JCOE LSAW Steel Pipe Manufacturing

- Floating Pipelines: Key Views on Offshore Dynamic Risers & Marine Transportation Pipelines

- The Dance of Spiral Forming: How SSAW Steel Pipes Are Made