Why Does Your “2-Inch” Steel Pipe Measure 2.375 Inches? A Guide to Steel Pipe Diameter Charts, o.D. I.D. And NPS

Introduction

A new purchasing expert or engineer ordered a “2-inch steel pipe“, but found that the outer edge of the steel pipe was 2.375 inches. This is not a mistake-this is the size system of steel pipe industry, in which “nominal” ≠ “practical”.

Its core is Nominal Pipe Size (NPS), which is a North American “label” (not a measure). In order to avoid wrong, delayed or mismatched parts, anyone who uses steel pipe must understand NPS, outside diameter (O. Outside diameter) and inside diameter (inside diameter).

This guide breaks down these concepts, provides a chart of steel pipe size (according to global standards), explains measurement method, and answers common questions. By the end, you’ll never doubt the pipeline orders again.

Core concepts-—NPS, O.D.,I.D.

Master these basic knowledge before using a steel pipe size drawing.

1. What Is Nominal Pipe Size (NPS)?

Nominal Diameter (NPS) is a standardized compatibility “name”, not a measurement. ASME B 36.10 m has formulated the NPS standards for steel pipe.

Critical split was 12 inches.

· NPS ≤ 12: NPS ≠ Outside diameter of steel pipe (e.g., NPS 2 = 2.375 external diameter, NPS 1 = 1.315 external diameter).

· NPS ≥ 14: NPS = outer diameter of steel pipe (e.g., NPS 14 = 14 outer diameter NPS 24 = 24 outer diameter)

This balances historical inner-flow standards with modern fitting compatibility.

2. Outside diameter (O.D.) Fixed dimension

Unlike NPS, the outer diameter of steel pipe is fixed according to the size of NPS. This ensures that different brands of fittings (elbows, tees) are suitable for the same NPS pipeline.

Examples:

Nominal diameter 1/2: external diameter = 0.840 inches.

Outside diameter = 2.375 inches.

Outside diameter = 16.000 inches.

3. The inner diameter (I.D.) Variable size

The inner diameter depends on fixed outer diameter (according to NPS) and wall thickness.

Wall thickness is defined by SCHedule (sch) (ASME B 36.10 m).

· SCH 40: general application

· SCH 80: High Pressure/Temperature

· School 160/XS: heavy industry

Inner diameter = outer diameter (2 x wall thickness). For example, NPS 2 SCH 40 = 2.067 inner diameter. NPS 2 SCH 80 = 1.939 inner diameter-different flow rates.

Steel pipe dimension drawing (ASME B36.10M)

The steel pipe size drawing includes the general NPS sizes, outer diameter, SCH values, wall thicknesses and inner diameter (source: ASME B 36.10 m).

| NPS (in) | Outside Diameter (O.D.) (in) | Schedule (SCH) | Wall Thickness (in) | Inside Diameter (I.D.) (in) |

| 1/2” | 0.840 | 40 | 0.109 | 0.622 |

| 1/2” | 0.840 | 80 | 0.147 | 0.546 |

| 3/4” | 1.050 | 40 | 0.113 | 0.824 |

| 3/4” | 1.050 | 80 | 0.154 | 0.742 |

| 1” | 1.315 | 40 | 0.133 | 1.049 |

| 1” | 1.315 | 80 | 0.179 | 0.957 |

| 1-1/4” | 1.660 | 40 | 0.140 | 1.380 |

| 1-1/4” | 1.660 | 80 | 0.191 | 1.278 |

| 1-1/2” | 1.900 | 40 | 0.145 | 1.610 |

| 1-1/2” | 1.900 | 80 | 0.200 | 1.500 |

| 2” | 2.375 | 40 | 0.154 | 2.067 |

| 2” | 2.375 | 80 | 0.218 | 1.939 |

| 3” | 3.500 | 40 | 0.216 | 3.068 |

| 3” | 3.500 | 80 | 0.300 | 2.900 |

| 4” | 4.500 | 40 | 0.237 | 4.026 |

| 4” | 4.500 | 80 | 0.337 | 3.826 |

| 6” | 6.625 | 40 | 0.280 | 6.065 |

| 6” | 6.625 | 80 | 0.432 | 5.761 |

| 8” | 8.625 | 40 | 0.322 | 8.001 |

| 8” | 8.625 | 80 | 0.500 | 7.625 |

| 10” | 10.750 | 40 | 0.365 | 10.020 |

| 10” | 10.750 | 80 | 0.594 | 9.562 |

| 12” | 12.750 | 40 | 0.406 | 11.938 |

| 12” | 12.750 | 80 | 0.688 | 11.374 |

| 14” | 14.000 | 40 | 0.438 | 13.124 |

| 14” | 14.000 | 80 | 0.750 | 12.500 |

| 16” | 16.000 | 40 | 0.500 | 15.000 |

| 16” | 16.000 | 80 | 0.844 | 14.312 |

| 18” | 18.000 | 40 | 0.562 | 16.876 |

| 18” | 18.000 | 80 | 0.938 | 16.124 |

| 20” | 20.000 | 40 | 0.625 | 18.750 |

| 20” | 20.000 | 80 | 1.031 | 17.938 |

| 24” | 24.000 | 40 | 0.750 | 22.500 |

| 24” | 24.000 | 80 | 1.219 | 21.562 |

How to Measure Steel Pipe Dimensions

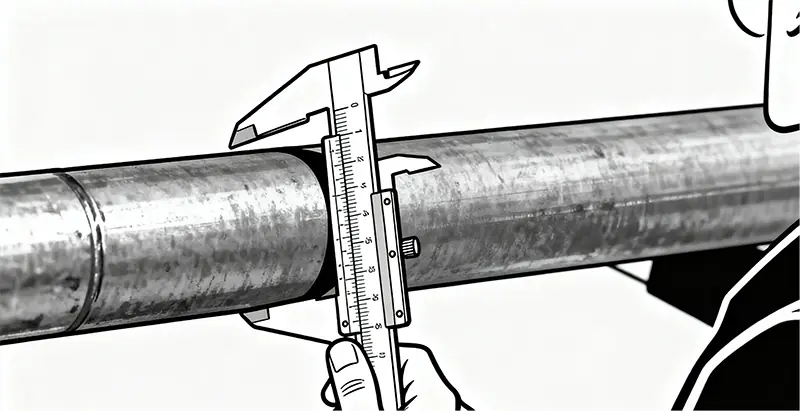

For high-stakes projects (oil/gas, chemicals), use a caliper and straightedge.

Step 1: Measure O.D.

1. Clean the pipeline (debris can distort the pipeline).

2. Place the clamp jaws around the pipeline perpendicular to the length of the pipeline.

3. Measure for 3 times (top/bottom/side).

4. Average values of actual outer diameter of steel pipe; Cross-check with the steel pipe size chart to confirm NPS.

Step 2: Measure wall thickness

1. Make a line along the pipeline.

2. Align the jaw of the caliper with the mark (inner/outer edges).

3. Measure for 3 times along the route.

4. Mean values; Find the corresponding SCH on the steel tube size table.

Step 3: Calculate the I.D.

Usage: inner diameter = outer diameter (2 × wall thickness.

For example: NPS 2 pipeline (O. Diameter 2.375, wall thickness 0.154) → inner diameter = 2.067 (matching SCH 40).

Conclusion

With the disappearance of this core relationship, the confusion also disappeared.

NPS is a label (separated by 12 inches to facilitate outside diameter alignment).

The outer diameter is fixed (to ensure the compatibility of accessories).

The inner diameter changes with SCH (determines the flow/pressure capacity).

This knowledge avoids costly mistakes-wrong steel pipe size will delay construction or damage equipment. Use the chart and steps here to get the correct orders.

FAQ

Q 1: NPS vs DN (nominal diameter)

NPS is in North America (inches); DN is internationally accepted (ISO, mm). Rough transformation (according to the standards):

NPS 1/2 = DN 15, NPS 1 = DN 25, NPS 2 = DN 50, NPS 4 = DN 100, NPS 6 = DN 150.

DN is also a label, and it is not an accurate mm measurement.

Q 2: Does Schedule 40 mean 40 psi?

No. SCH defines the wall thickness of steel pipe, which is independent of pressure.

Pressure depends on material (carbon steel/stainless steel), temperature and SCH. Calculated by ASME B 31 specification (source: ASME b31.3); SCH 40 carbon steel can withstand a pressure of 1000+PSI at room temperature.

Q 3: Why is the outer diameter of NPS 2 pipeline 2.375?

Welded steel pipe in the 19th century were sized according to the inner diameter (for flowing), so “2 inch means 2 inch of inner diameter. Seamless manufacturing later standardized the outer diameter (for fittings), but kept NPS label-2.375.

Share:

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.

Related Articles

ASTM A53 vs. API 5L: A Guide to Selection and Application

Introduction:Technology differences determine success or failure, and selection needs to be “precise”

Steel Density Analysis: Core Differences between Mild and Medium Carbon Steels and Industrial Applications

3LPE coated steel pipe: a solid barrier in the field of industrial corrosion protection

3LPP coated pipe: anti-corrosion guard in high temperature and high pressure environment

FBE steel pipe: the technological armor of the steel defense line

HOT TAGS

latest posts

- 3LPE coated steel pipe: a solid barrier in the field of industrial corrosion protection

- Breakthrough of spiral welded pipe technology: How does SSAW steel pipe conquer the water supply project in rugged mountain areas of South America?

- What is offshore pipeline and its Applications in offshore oil and gas development

- 3PP Coating for High-Temp Pipe Corrosion | Case Study

- A Guide to ISO 21809: 3LPE & FBE Pipe Coating Standards