UOE Process: High-Efficiency LSAW Pipe Manufacturing

A project manager is now sourcing 50 kilometers of large-diameter LSAW pipe for a mission-critical cross-country natural gas pipeline. It’s an aggressive schedule with an exceptionally tight specification on dimensional accuracy. Finding a supplier is the easy part, the difficult part is ensuring the supplier is able to consistently produce high quality and meet the production rate.

The secret to satisfying this demand lies as much in the raw material as in the basic pipe manufacturing technology. For high volume, standardised production projects, it is vital to understand the difference between the LSAW forming process methods. UOE processing is very capital intensive and highly automated process which is a quite different answer made for this exact type of problem.

In this article, you will learn a technical step-by-step process analysis of UOE process of LSAW steel pipe. We are going to dissect the phases of the mechanical expansion process: from forming at the outset to the critical mechanical expansion, showing a data driven analysis of how it benefits your production efficiency and quality of the final product.This will give engineers and purchasing managers a concise decision-making guide.

The UOE Process: A Step-by-Step Technical Breakdown

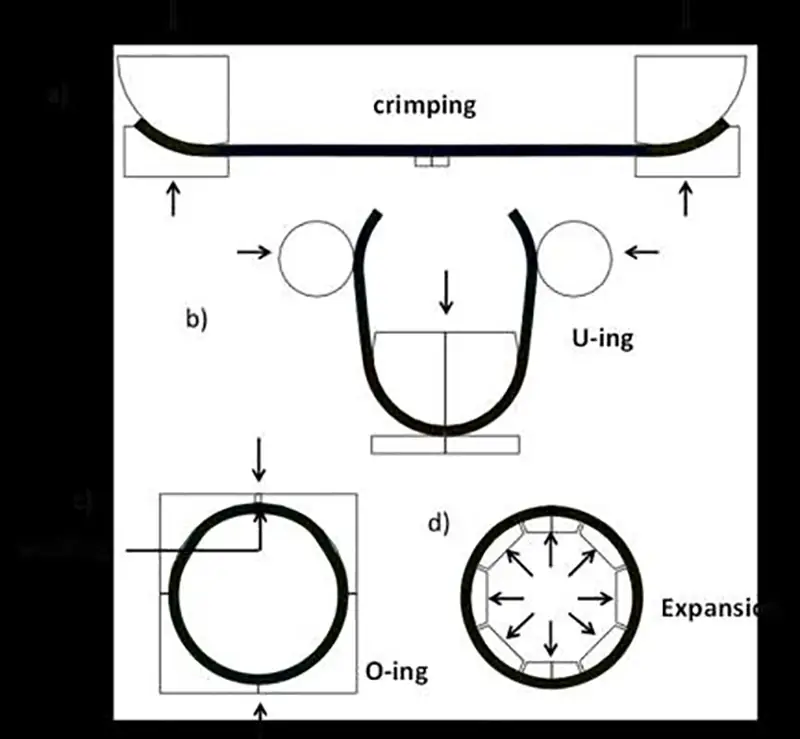

The term UOE the process is referred to the forming processes of U-ing, O-ing and Expanding which represents qualities main sequential steps of the process. It is characterized by extremely high production rates, being very well suited for producing large diameter and thick walls LSAW pipes.

1. Pre-Processing: Preparing the Steel Plate

The raw steel plate is processed through two essential preparation stages prior to forming. The first is Edge Milling, where the plate edges are milled to the proper weld fit-up geometry. Then there is Edge Crimping, Edge Crimping: A powerful press bends the very edges of the plate to the curvature of the finished pipe.”Crimp” is also called flanging, perform flange 4.0mm for 1.0mm thickness pipe~no more than.10mm-thick pipe before heating ripening spiral. This first crimp avoids imperfections in the O-ing main stage and guarantees a perfectly circular profile.

2. The U-ing Press: The First Forming Stage

Next, the prepared steel plate is transferred to the U-ing press. Here, a colossal, top die — which curves like a ”U” — comes crashing down and smashes the flat panel into a “U” form with incredible force. It is performed in one single stroke and it is very fast which makes the successive forming step possible.

3. The O-ing Press: Final Forming and Welding

The U-shaped plate is moved to the O-ing press. This is a press with a very powerful semi-circular top die that comes down and close the “U” in a “O” (practically a circle tube) . The two milled edges are now perfectly matched. While subjected to pressure in the O-press, the joint is tack welded and then internally and externally submerged arc welded (SAW) to produce a high quality, continuous weld joint.

4. The “E”: Mechanical Expanding – The Core of the UOE Process

This stage is what truly defines the UOE process and gives its products superior qualities. After welding, the pipe is moved to a mechanical expander. An internal expansion head with multiple segments is inserted into the pipe and hydraulically expanded, pushing outwards against the pipe’s inner walls. This action does several critical things simultaneously:

· Sizes the pipe to its exact final diameter with outstanding accuracy.

· Perfects its circularity (out-of-roundness).

· Straightens the pipe along its entire length.

· Relieves internal stresses that were induced during the forming and welding processes. This phenomenon, known as the Bauschinger effect, significantly improves the pipe’s final mechanical properties.

5. Final Testing and Inspection

Post-expansion, each pipe is tested through a rigorous series of tests, such as hydrostatic testing, ultrasonic testing (UT) of weld seam and pipe body, and dimensional checks for confirming that it meets all project and international standard requirements including API 5L.

Quantitative Analysis: UOE vs. JCOE Process

| Feature | UOE Process | JCOE Process | Quantifiable Metric / Rationale |

| Production Efficiency | High-Speed, Continuous Flow | Slower, Incremental Forming | UOE lines are automated for mass production, often achieving rates of up to 60 pipes/hour for certain sizes. |

| Dimensional Accuracy | Excellent | Very Good | The mandatory mechanical expansion stage in the UOE process ensures superior circularity and diameter tolerance, typically within ±0.5% of the diameter. |

| Residual Stress | Low | Moderate | Mechanical expansion actively relieves internal stresses, leading to better material stability and resistance to stress corrosion cracking. |

| Diameter Flexibility | Limited | High | UOE tooling is specific to a narrow range of diameters. JCOE presses are more adaptable to producing smaller batches of varied sizes. |

| Capital Investment | Very High | High | The specialized, high-tonnage U- and O-presses and the mechanical expander make UOE a significantly higher initial investment. |

The UOE process is a high technology LSAW pipe manufacturing process due to its efficiency, automation, and the unique last step of mechanical expansion.This expansion step is directly the source for the essential benefits of the method: high dimensional accuracy and low residual stresses in the end-product.

The choice between manufacturing processes should be driven by project specifics.

· Select a provider that uses the UOE process: If your project needs a very large volume of a standard pipe diameter, the production schedule is tight, and the technical requirements to achieve the tightest tolerances in dimensions is a critical facto.

· Consider a supplier employing a technique such as JCOE:when Your project deals with small volumes across different pipe diameters, needing more flexibility in production, or if the highest production velocity is not the principal driver in your costs.

In the end, knowing the technology of the product is the key for the purchasing success. At Allland Steel Pipe, we do more than just LSAW pipe, we offer the technical transparency and know-how that allows you to choose the best processing route for your unique project schedule/specification/budget trade off.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.

Related Articles

ASTM A53 vs. API 5L: A Guide to Selection and Application

Introduction:Technology differences determine success or failure, and selection needs to be “precise”

Steel Density Analysis: Core Differences between Mild and Medium Carbon Steels and Industrial Applications

3LPE coated steel pipe: a solid barrier in the field of industrial corrosion protection

3LPP coated pipe: anti-corrosion guard in high temperature and high pressure environment

FBE steel pipe: the technological armor of the steel defense line

HOT TAGS

latest posts

- 3LPE coated steel pipe: a solid barrier in the field of industrial corrosion protection

- Breakthrough of spiral welded pipe technology: How does SSAW steel pipe conquer the water supply project in rugged mountain areas of South America?

- What is offshore pipeline and its Applications in offshore oil and gas development

- 3PP Coating for High-Temp Pipe Corrosion | Case Study

- A Guide to ISO 21809: 3LPE & FBE Pipe Coating Standards