HOT PRODUCTS TAGS

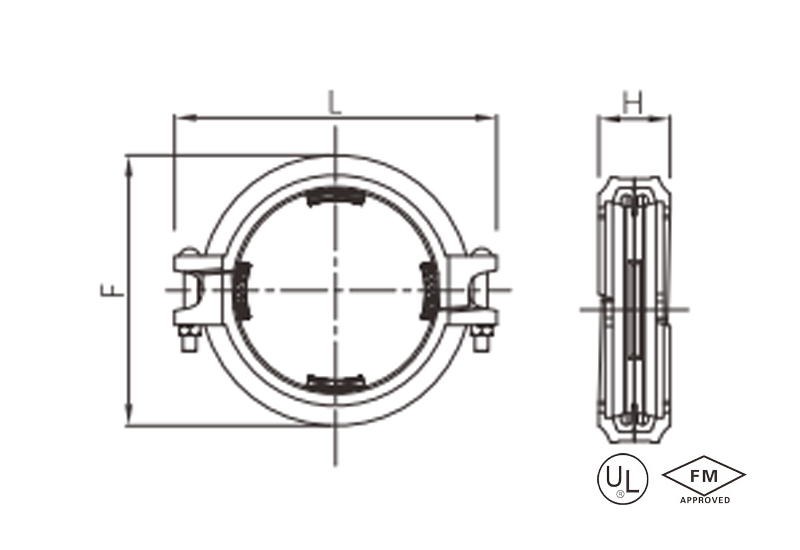

Quick rigid grooved coupling

·Standard: ANSI / UL 213 UL / FM

·Material: Ductile iron ASTM A536, 65-45-12

·Bolt & nut: Carbon steel

·Gasket: EPDM, nitrile, silicone rubber, etc

·Rated pressure: 300 – 500 psi

·Surface: Red painting / hot dip galvanized

·Size range: 1-1/4″×12″

description

Quick rigid grooved coupling is a rigid pipe joint that achieves rigid connection between pipes through clamps and bolts. It significantly shortens the installation time while ensuring a stable connection and is suitable for pipeline systems with high requirements for sealing and installation efficiency

Specification

Available size

Size | Dimension (mm) | Bolting (n x bolt size) | |||||

Inch | DN | mm | F | L | H | ANSI | EN |

1-1/4″ | 32 | 42.4 | 65 | 108 | 47 | 2 – 3/8″ × 60 | 2 – M10 × 57 |

1-1/2″ | 40 | 48.3 | 72 | 115 | 47 | 2 – 3/8″ × 60 | 2 – M10 × 57 |

2″ | 50 | 60.3 | 85 | 126 | 48 | 2 – 3/8″ × 60 | 2 – M10 × 57 |

2-1/2″ | 65 | 73.0 | 97 | 140 | 48 | 2 – 3/8″ × 60 | 2 – M10 × 57 |

2-1/2″ | 65 | 76.1 | 100 | 140 | 48 | 2 – 3/8″ × 60 | 2 – M10 × 57 |

3″ | 80 | 88.9 | 112 | 160 | 48 | 2 – 3/8″ × 60 | 2 – M10 × 63 |

4″ | 100 | 114.3 | 138 | 194 | 50 | 2 – 1/2″ × 65 | 2 – M12 × 70 |

5″ | 125 | 139.7 | 168 | 226 | 50 | 2 – 1/2″ × 65 | 2 – M12 × 70 |

5″ | 125 | 141.3 | 170 | 228 | 50 | 2 – 1/2″ × 65 | 2 – M12 × 70 |

6″ | 150 | 165.1 | 191 | 249 | 51 | 2 – 1/2″ × 80 | 2 – M12 × 82 |

6″ | 150 | 168.3 | 198 | 257 | 51 | 2 – 1/2″ × 80 | 2 – M12 × 82 |

8″ | 200 | 219.1 | 252 | 323 | 61 | 2 – 5/8″ × 85 | 2 – M16 × 89 |

10″ | 250 | 273.0 | 349 | 432 | 70 | 2 – 7/8″ × 6-1/2″ | 2 – M22 × 165 |

12″ | 300 | 323.9 | 406 | 483 | 70 | 2 – 7/8″ × 6-1/2″ | 2 – M22 × 165 |

application

- Emergency repairs & rapid construction: Mainly suitable for projects of tight schedule or emergency repair scenario, with the example scenarios like emergency repair of municipal water pipes, quick replacement of factory pipes and fire system retrofit etc.

- Space-constrained operations: Designed for use in narrow trenches, high-altitude work and other environments where large tools are not easy to operate, the installation process is more streamlined.

- High sealing standard: UL / FM certified, can be used on important pipeline systems in hospitals, laboratories and other places where leaks are not allowed at all.

- Any Pipe Connections: Powder coating finish with no edges, covering steel pipes and ductile iron pipes.

advantages

1. Quick and easy installation in a matter of minutes: Its snap-fit design allows for sealing from the outside with two bolts so the time spent is only a receiver when compared to traditional methods;

2. Stability absolute : A stable mode which the circular structure fixes tube to ensure enough earthquake resistance and prevent a pipe out of position for long time alignment.

3. 100% leakproof sealing: Adopt high-quality rubber gaskets, excellent water, oil or gas media permeability zero leaks safe and reliable performance.

4. Singe person operation: Light weight allow without auxiliary equipment or multiple operators, Savi small labor cost.

5. Rust protection with a lifespan: The use of a high-strength cast iron and coating to prevent corrosion in permanent, damp or subterranean installations.

6. Low maintenance cost: Demountable, can be used directly after inspection, saving time and material cost.

packing

- Ready-to-use portable packaging:

- Each item comes in an individual cardboard box (with shock-resistant inner lining), ready to install upon opening, with a simple installation diagram included.

- Outer box clearly labeled: Quick-connect fitting, 4 inches, for emergency repairs.

- Large-size smart protection:

- 6 inches and above feature an integrated handle design for easy handling; internal bolts/washers are stored in separate compartments to prevent loss.

- Optimized for bulk transportation:

- Flat cardboard boxes are stacked on pallets and secured with stretch film to maximize loading capacity, suitable for emergency supply transportation.

Available size

Size | Dimension (mm) | Bolting (n x bolt size) | |||||

Inch | DN | mm | F | L | H | ANSI | EN |

1-1/4″ | 32 | 42.4 | 65 | 108 | 47 | 2 – 3/8″ × 60 | 2 – M10 × 57 |

1-1/2″ | 40 | 48.3 | 72 | 115 | 47 | 2 – 3/8″ × 60 | 2 – M10 × 57 |

2″ | 50 | 60.3 | 85 | 126 | 48 | 2 – 3/8″ × 60 | 2 – M10 × 57 |

2-1/2″ | 65 | 73.0 | 97 | 140 | 48 | 2 – 3/8″ × 60 | 2 – M10 × 57 |

2-1/2″ | 65 | 76.1 | 100 | 140 | 48 | 2 – 3/8″ × 60 | 2 – M10 × 57 |

3″ | 80 | 88.9 | 112 | 160 | 48 | 2 – 3/8″ × 60 | 2 – M10 × 63 |

4″ | 100 | 114.3 | 138 | 194 | 50 | 2 – 1/2″ × 65 | 2 – M12 × 70 |

5″ | 125 | 139.7 | 168 | 226 | 50 | 2 – 1/2″ × 65 | 2 – M12 × 70 |

5″ | 125 | 141.3 | 170 | 228 | 50 | 2 – 1/2″ × 65 | 2 – M12 × 70 |

6″ | 150 | 165.1 | 191 | 249 | 51 | 2 – 1/2″ × 80 | 2 – M12 × 82 |

6″ | 150 | 168.3 | 198 | 257 | 51 | 2 – 1/2″ × 80 | 2 – M12 × 82 |

8″ | 200 | 219.1 | 252 | 323 | 61 | 2 – 5/8″ × 85 | 2 – M16 × 89 |

10″ | 250 | 273.0 | 349 | 432 | 70 | 2 – 7/8″ × 6-1/2″ | 2 – M22 × 165 |

12″ | 300 | 323.9 | 406 | 483 | 70 | 2 – 7/8″ × 6-1/2″ | 2 – M22 × 165 |

- Emergency repairs & rapid construction: Mainly suitable for projects of tight schedule or emergency repair scenario, with the example scenarios like emergency repair of municipal water pipes, quick replacement of factory pipes and fire system retrofit etc.

- Space-constrained operations: Designed for use in narrow trenches, high-altitude work and other environments where large tools are not easy to operate, the installation process is more streamlined.

- High sealing standard: UL / FM certified, can be used on important pipeline systems in hospitals, laboratories and other places where leaks are not allowed at all.

- Any Pipe Connections: Powder coating finish with no edges, covering steel pipes and ductile iron pipes.

1. Quick and easy installation in a matter of minutes: Its snap-fit design allows for sealing from the outside with two bolts so the time spent is only a receiver when compared to traditional methods;

2. Stability absolute : A stable mode which the circular structure fixes tube to ensure enough earthquake resistance and prevent a pipe out of position for long time alignment.

3. 100% leakproof sealing: Adopt high-quality rubber gaskets, excellent water, oil or gas media permeability zero leaks safe and reliable performance.

4. Singe person operation: Light weight allow without auxiliary equipment or multiple operators, Savi small labor cost.

5. Rust protection with a lifespan: The use of a high-strength cast iron and coating to prevent corrosion in permanent, damp or subterranean installations.

6. Low maintenance cost: Demountable, can be used directly after inspection, saving time and material cost.

- Ready-to-use portable packaging:

- Each item comes in an individual cardboard box (with shock-resistant inner lining), ready to install upon opening, with a simple installation diagram included.

- Outer box clearly labeled: Quick-connect fitting, 4 inches, for emergency repairs.

- Large-size smart protection:

- 6 inches and above feature an integrated handle design for easy handling; internal bolts/washers are stored in separate compartments to prevent loss.

- Optimized for bulk transportation:

- Flat cardboard boxes are stacked on pallets and secured with stretch film to maximize loading capacity, suitable for emergency supply transportation.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.