HOT PRODUCTS TAGS

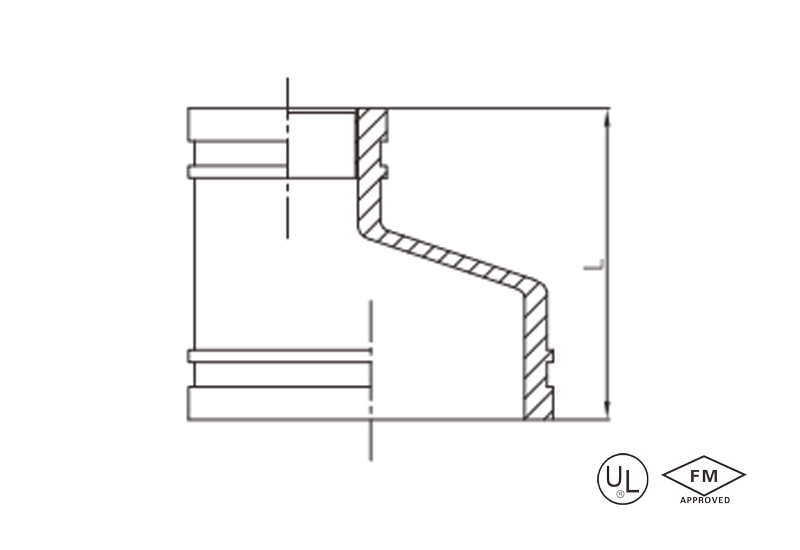

Grooved eccentric reducer with female threaded outlet

·Standard: ANSI / UL 213C UL / FM

·Material: Ductile iron ASTM A536, 65-45-12

·Type: Short / Standard

·Branch: Female thread, NPT / BSPT

·Rated pressure: 300 – 500 psi

·Surface: Red painting / hot dip galvanized

·Size range: 4″×2-1/2″ – 6″×3″

description

Grooved eccentric reducer with female threaded outlet is an eccentric reducer with different diameters at both ends and a misaligned centerline, and the outlet end is designed with an internal thread. It is used to connect pipes of different diameters, to prevent fluid accumulation or gas blockage, and to fit internal threaded components

Specification

Available size

Size | End to end | ||

Inch | DN | mm | L(mm) |

4″ × 2-1/2″ | 100 × 65 | 114.3 × 76.1 | 102 |

5″ × 3″ | 125 × 80 | 139.7 × 88.9 | 127 |

6″ × 3″ | 150 × 80 | 165.1 × 88.9 | 140 |

application

- Fire protection systems: Building fire protection pipe diameter conversion connections, adapting to different pipe diameters for pump valve and pipe network connections.

- HVAC engineering: Transporting gas/liquid in air conditioning hot and cold water pipes, preventing liquid accumulation in inclined pipe sections.

- Industrial pipes: Connecting internal threaded instruments, valves, and other equipment in chemical and water supply and drainage systems.

- Special conditions: Inclined/horizontal pipe diameter conversion sections where air blockages or residual liquid accumulation must be prevented.

advantages

1. Anti-clogging and blocking: Eccentric structure make sure there is no crimping phenomenon in the corresponding tube.

2. Save time in labor with grooved connection (no welding is necessary) and direct screw-on assembly through internal threaded interface.

3. High-strength & long lifetime: Made of Ductile Iron, withstands pressure and impact plus hot-dip galvanized/coated proceeded surface, 50%+ life expectancy.

4. Safety certification: UL/FM internationally certified to be safe and the system can work with 150–300 psi orhigher.

5. Flexible Compatibility: NPT and BSPT thread standards, universal to global standard pipe fittings

packing

- Single-item protection: Surface coated with anti-rust oil film + bubble wrap packaging to prevent scratches and moisture damage.

- Standard packaging: Corrugated cardboard boxes with foam inserts for secure positioning. Each box includes product labels, certificates of conformity, and installation instructions.

- Reinforced packaging for large sizes: Custom wooden boxes (additional charge) are provided for sizes 6″ and above, with steel straps securing the box.

- Clear labeling: The outer box is printed with the product name, dimensions, quantity, weight, and “This Side Up” and “Keep Dry” icons.

Available size

Size | End to end | ||

Inch | DN | mm | L(mm) |

4″ × 2-1/2″ | 100 × 65 | 114.3 × 76.1 | 102 |

5″ × 3″ | 125 × 80 | 139.7 × 88.9 | 127 |

6″ × 3″ | 150 × 80 | 165.1 × 88.9 | 140 |

- Fire protection systems: Building fire protection pipe diameter conversion connections, adapting to different pipe diameters for pump valve and pipe network connections.

- HVAC engineering: Transporting gas/liquid in air conditioning hot and cold water pipes, preventing liquid accumulation in inclined pipe sections.

- Industrial pipes: Connecting internal threaded instruments, valves, and other equipment in chemical and water supply and drainage systems.

- Special conditions: Inclined/horizontal pipe diameter conversion sections where air blockages or residual liquid accumulation must be prevented.

1. Anti-clogging and blocking: Eccentric structure make sure there is no crimping phenomenon in the corresponding tube.

2. Save time in labor with grooved connection (no welding is necessary) and direct screw-on assembly through internal threaded interface.

3. High-strength & long lifetime: Made of Ductile Iron, withstands pressure and impact plus hot-dip galvanized/coated proceeded surface, 50%+ life expectancy.

4. Safety certification: UL/FM internationally certified to be safe and the system can work with 150–300 psi orhigher.

5. Flexible Compatibility: NPT and BSPT thread standards, universal to global standard pipe fittings

- Single-item protection: Surface coated with anti-rust oil film + bubble wrap packaging to prevent scratches and moisture damage.

- Standard packaging: Corrugated cardboard boxes with foam inserts for secure positioning. Each box includes product labels, certificates of conformity, and installation instructions.

- Reinforced packaging for large sizes: Custom wooden boxes (additional charge) are provided for sizes 6″ and above, with steel straps securing the box.

- Clear labeling: The outer box is printed with the product name, dimensions, quantity, weight, and “This Side Up” and “Keep Dry” icons.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.