HOT PRODUCTS TAGS

Grooved reducing tee wye

·Standard: ANSI / UL 213C FM

·Material: Ductile iron ASTM A536, 65-45-12

·Rated pressure: 300 – 500 psi

·Surface: Black / red painting / hot dip galvanized

·Size range: 4”×4”×2-1/2′

description

Grooved reducing tee wye is a reducer inclined three-way pipe fitting. The branch interface is inclined at a certain Angle to the main pipeline and has a different pipe diameter. It is used to achieve the inclined branch connection of the reducer pipeline and facilitate the smooth transition of the fluid.

Specification

Available size

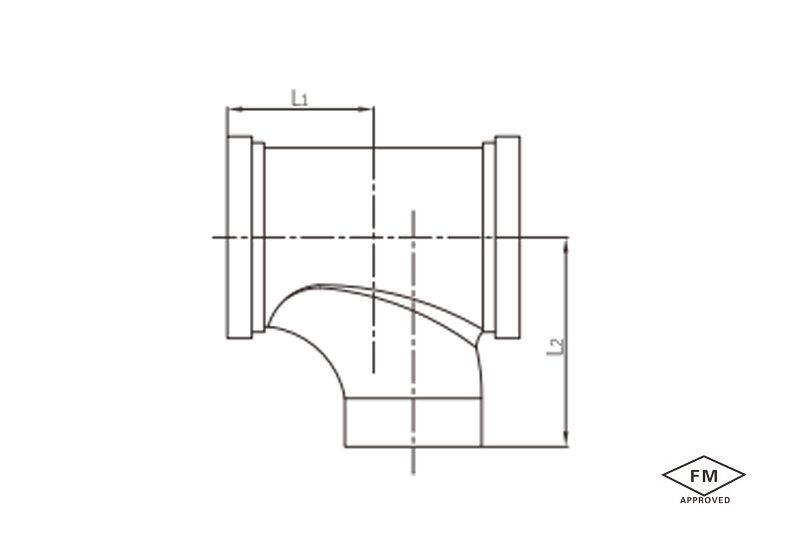

| Size | Center to end(mm) | |||

| Inch | DN | mm | L1 | L2 |

| 4” × 4” × 2-1/2” | 100 × 100 × 65 | 114.3 × 114.3 × 76.1 | 96 | 134.5 |

application

- Smooth transition: The fluid transferring tool is specifically designed for connections with inclined branches of different pipe diameters, and the branch pipes are connected at a 45°angle to the main channel to reduce fluid resistance.

- Space-efficient layout: Applicable in more complex situations, where pipe systems are to circumvent obstacles (like beam, column and equipment).

- Industrial fluid systems: such as those in chemical engineering or for HVAC systems, where the flow needs to be directed from one pipe of a certain diameter to another.

advantages

1. Hydraulic Efficiency Improvement — Angled branch shape reduces turbulence, leading to higher flow efficiency and energy savings of the system.

2. One-Piece Ductile Iron Body for Compact Structure, ASTM A536-cast without weld seam risk of pressure leak-welded end nippled connections rated to 300-500 psi

3. Installations Convenience: Thanks to the use of grooved connections, which does not require any special tool but uses easy-to-install click technology and that allows fast assembly and reduces installation time by more than 50%.

4. Wide application: Black paint/red paint or hot-dip galvanized surface treatment; it is the best choice to use in corrosive media and humid environments.

5. ANSI/UL/FM certified ensuring safe and effective certification for fire protection and industrial systems

packing

- Protection of inclined surfaces: Replace the delicate foam corner protectors that cover the inclined interfaces, and place them to prevent deformation caused by bumps during transport.

- Moisture-proof packaging: all items are individually vacuumed with rust-proof film, put in a moisture-proof carton and filled with desiccant.

- Obvious labelling: Carton is printed with ↑ Inclined surface facing up and Do not crush icon with sizing labels for easy warehouse management(s).

Available size

| Size | Center to end(mm) | |||

| Inch | DN | mm | L1 | L2 |

| 4” × 4” × 2-1/2” | 100 × 100 × 65 | 114.3 × 114.3 × 76.1 | 96 | 134.5 |

- Smooth transition: The fluid transferring tool is specifically designed for connections with inclined branches of different pipe diameters, and the branch pipes are connected at a 45°angle to the main channel to reduce fluid resistance.

- Space-efficient layout: Applicable in more complex situations, where pipe systems are to circumvent obstacles (like beam, column and equipment).

- Industrial fluid systems: such as those in chemical engineering or for HVAC systems, where the flow needs to be directed from one pipe of a certain diameter to another.

1. Hydraulic Efficiency Improvement — Angled branch shape reduces turbulence, leading to higher flow efficiency and energy savings of the system.

2. One-Piece Ductile Iron Body for Compact Structure, ASTM A536-cast without weld seam risk of pressure leak-welded end nippled connections rated to 300-500 psi

3. Installations Convenience: Thanks to the use of grooved connections, which does not require any special tool but uses easy-to-install click technology and that allows fast assembly and reduces installation time by more than 50%.

4. Wide application: Black paint/red paint or hot-dip galvanized surface treatment; it is the best choice to use in corrosive media and humid environments.

5. ANSI/UL/FM certified ensuring safe and effective certification for fire protection and industrial systems

- Protection of inclined surfaces: Replace the delicate foam corner protectors that cover the inclined interfaces, and place them to prevent deformation caused by bumps during transport.

- Moisture-proof packaging: all items are individually vacuumed with rust-proof film, put in a moisture-proof carton and filled with desiccant.

- Obvious labelling: Carton is printed with ↑ Inclined surface facing up and Do not crush icon with sizing labels for easy warehouse management(s).

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.