HOT PRODUCTS TAGS

Grooved reducing tee

·Standard: ANSI / UL 213C UL / FM

·Material: Ductile iron ASTM A536, 65-45-12

·Type: Short / Standard

·Rated pressure: 300 – 500 psi

·Surface: Red painting / hot dip galvanized

·Size range: 2″×1″ – 14″×8″

description

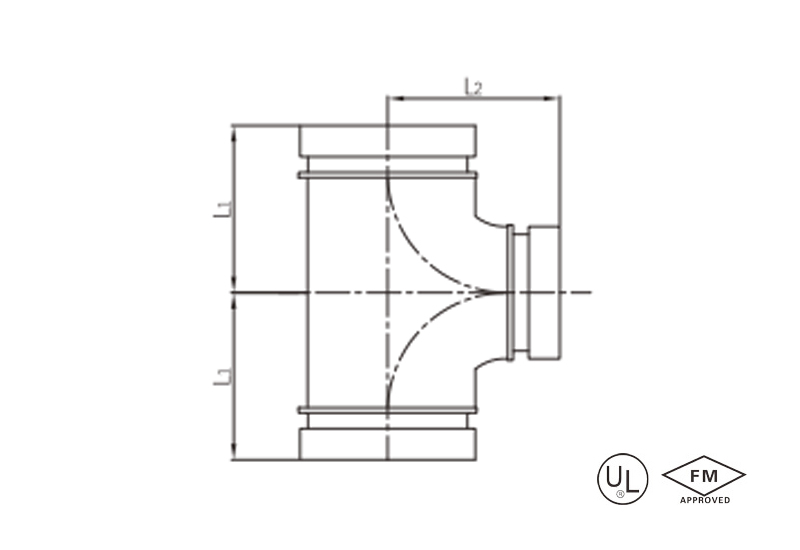

Grooved reducing tee is a reducer three-way pipe fitting with a grooved connection structure. The pipe diameters of the three interfaces are not exactly the same, and it is used to achieve vertical branch connections of pipelines with different pipe diameters

Specification

Available size

| Size | Center to end (mm),Short | Center to end (mm),Standard | ||||

| Inch | DN | mm | L1 | L2 | L1 | L2 |

| 2″ × 1″ | 50 × 25 | 60.3 × 33.7 | 70 | 70 | 83 | 83 |

| 2″ × 1-1/4″ | 50 × 32 | 60.3 × 42.4 | 70 | 70 | / | / |

| 2″ × 1-1/2″ | 50 × 40 | 60.3 × 48.3 | 70 | 70 | 83 | 83 |

| 2-1/2″ × 1″ | 65 × 25 | 73.0 × 33.7 | 76 | 76 | 95 | 95 |

| 2-1/2″ × 1-1/4″ | 65 × 32 | 73.0 × 42.4 | 76 | 76 | 95 | 95 |

| 2-1/2″ × 1-1/2″ | 65 × 40 | 73.0 × 48.3 | 76 | 76 | 95 | 95 |

| 2-1/2″ × 2″ | 65 × 50 | 73.0 × 60.3 | 76 | 76 | 95 | 95 |

| 2-1/2″ × 1″ | 65 × 25 | 76.1 × 33.7 | 76 | 76 | / | / |

| 2-1/2″ × 1-1/4″ | 65 × 32 | 76.1 × 42.4 | 76 | 76 | / | / |

| 2-1/2″ × 1-1/2″ | 65 × 40 | 76.1 × 48.3 | 76 | 76 | / | / |

| 2-1/2″ × 2″ | 65 × 50 | 76.1 × 60.3 | 76 | 76 | / | / |

| 3″ × 1″ | 80 × 25 | 88.9 × 33.7 | 86 | 86 | 108 | 108 |

| 3″ × 1-1/4″ | 80 × 32 | 88.9 × 42.4 | 86 | 86 | 108 | 108 |

| 3″ × 1-1/2″ | 80 × 40 | 88.9 × 48.3 | 86 | 86 | 108 | 108 |

| 3″ × 2″ | 80 × 50 | 88.9 × 60.3 | 86 | 86 | 108 | 108 |

| 3″ × 2-1/2″ | 80 × 65 | 88.9 × 73.0 | 86 | 86 | 108 | 108 |

| 3″ × 2-1/2″ | 80 × 65 | 88.9 × 76.1 | 86 | 86 | / | / |

| 4″ × 1″ | 100 × 25 | 114.3 × 33.7 | 101 | 101 | 127 | 127 |

| 4″ × 1-1/2″ | 100 × 40 | 114.3 × 48.3 | 101 | 101 | 127 | 127 |

| 4″ × 2″ | 100 × 50 | 114.3 × 60.3 | 101 | 101 | 127 | 127 |

| 4″ × 2-1/2″ | 100 × 65 | 114.3 × 73.0 | 101 | 101 | 127 | 127 |

| 4″ × 2-1/2″ | 100 × 65 | 114.3 × 76.1 | 101 | 101 | / | / |

| 4″ × 3″ | 100 × 80 | 114.3 × 88.9 | 101 | 101 | 127 | 127 |

| 5″ × 1-1/2″ | 125 × 40 | 139.7 × 48.3 | 124 | 124 | / | / |

| 5″ × 2″ | 125 × 50 | 139.7 × 60.3 | 124 | 124 | / | / |

| 5″ × 2-1/2″ | 125 × 65 | 139.7 × 76.1 | 124 | 124 | / | / |

| 5″ × 3″ | 125 × 80 | 139.7 × 88.9 | 124 | 124 | / | / |

| 5″ × 4″ | 125 × 100 | 139.7 × 114.3 | 124 | 124 | / | / |

| 5″ × 2″ | 125 × 50 | 141.3 × 60.3 | 124 | 124 | / | / |

| 5″ × 3″ | 125 × 80 | 141.3 × 88.9 | 124 | 124 | 140 | 140 |

| 5″ × 4″ | 125 × 100 | 141.3 × 114.3 | 124 | 124 | 140 | 140 |

| 6″ × 1-1/2″ | 150 × 40 | 165.1 × 48.3 | 140 | 140 | / | / |

| 6″ × 2″ | 150 × 50 | 165.1 × 60.3 | 140 | 140 | / | / |

| 6″ × 2-1/2″ | 150 × 65 | 165.1 × 76.1 | 140 | 140 | / | / |

| 6″ × 3″ | 150 × 80 | 165.1 × 88.9 | 140 | 140 | / | / |

| 6″ × 4″ | 150 × 100 | 165.1 × 114.3 | 140 | 140 | / | / |

| 6″ × 5″ | 150 × 125 | 165.1 × 139.7 | 140 | 140 | / | / |

| 6″ × 1-1/2″ | 150 × 40 | 168.3 × 48.3 | 140 | 140 | / | / |

| 6″ × 2″ | 150 × 50 | 168.3 × 60.3 | 140 | 140 | 165 | 165 |

| 6″ × 2-1/2″ | 150 × 65 | 168.3 × 73.0 | 140 | 140 | 165 | 165 |

| 6″ × 2-1/2″ | 150 × 65 | 168.3 × 76.1 | 140 | 140 | / | / |

| 6″ × 3″ | 150 × 80 | 168.3 × 88.9 | 140 | 140 | 165 | 165 |

| 6″ × 4″ | 150 × 100 | 168.3 × 114.3 | 140 | 140 | 165 | 165 |

| 6″ × 5″ | 150 × 126 | 168.3 × 139.7 | 140 | 140 | / | / |

| 6″ × 5″ | 150 × 125 | 168.3 × 141.3 | 140 | 140 | 165 | 165 |

| 8″ × 2″ | 200 × 50 | 219.1 × 60.3 | 175 | 175 | / | / |

| 8″ × 2-1/2″ | 200 × 65 | 219.1 × 76.1 | 175 | 175 | / | / |

| 8″ × 3″ | 200 × 80 | 219.1 × 88.9 | 175 | 175 | / | / |

| 8″ × 4″ | 200 × 100 | 219.1 × 114.3 | 175 | 175 | 197 | 197 |

| 8″ × 5″ | 200 × 125 | 219.1 × 139.7 | 175 | 175 | / | / |

| 8″ × 6″ | 200 × 150 | 219.1 × 165.1 | 175 | 175 | / | / |

| 8″ × 6″ | 200 × 150 | 219.1 × 168.3 | 175 | 175 | 197 | 197 |

| 10″ × 4″ | 250 × 100 | 273.0 × 114.3 | 215 | 215 | / | / |

| 10″ × 4″ | 250 × 100 | 273.0 × 114.3 | 229 | 229 | / | / |

| 10″ × 6″ | 250 × 150 | 273.0 × 165.1 | 229 | 229 | / | / |

| 10″ × 6″ | 250 × 150 | 273.0 × 168.3 | 229 | 229 | / | / |

| 10″ × 8″ | 250 × 200 | 273.0 × 219.1 | 229 | 229 | / | / |

| 12″ × 4″ | 300 × 100 | 323.9 × 114.3 | 254 | 254 | / | / |

| 12″ × 6″ | 300 × 150 | 323.9 × 165.1 | 254 | 254 | / | / |

| 12″ × 6″ | 300 × 150 | 323.9 × 168.3 | 254 | 254 | / | / |

| 12″ × 8″ | 300 × 200 | 323.9 × 219.1 | 254 | 254 | / | / |

| 12″ × 10″ | 300 × 250 | 323.9 × 273.0 | 254 | 254 | / | / |

| 14″ × 8″ | 350 × 200 | 355.6 × 219.1 | 280 | 280 | 279 | 279 |

application

- Used for vertical branch connections in piping systems, it adapts to main pipes and branch pipes of different diameters.

- Suitable for fire protection, HVAC, industrial water supply, and drainage systems.

- It has significant advantages in renovation projects with limited space or requiring quick installation.

advantages

1. Flexible adaptation: Both sides of the three end interfaces can be combined into multiple pipe diameters, thereby simplifying the connection between pipes with different diameters.

2. Nickel coated groove: Ease of installation with no welding or specialist tools required = quick and efficient installation!

3. Certified products to ANSI/UL/FM international standards, high pressure resistance with reliability.

4. Facilitative maintenance: Modular design enables local fault repair and lessens need for system-wide repairs.

5. Rust-Resistant and Lasting: Silver painted or hot-dipped galvanized surface, conducive to natural wet corrosion conditions.

packing

- Individual items are wrapped in bubble wrap to prevent scratches and placed securely in pressure-resistant cardboard boxes.

- Large pipe fittings are reinforced with custom wooden boxes and filled with shock-absorbing materials.

- The boxes are labeled with the product model, dimensions, and protective markings to ensure safe transport.

Available size

Size | Center to end (mm),Short | Center to end (mm),Standard | ||||

Inch | DN | mm | L1 | L2 | L1 | L2 |

2″ × 1″ | 50 × 25 | 60.3 × 33.7 | 70 | 70 | 83 | 83 |

2″ × 1-1/4″ | 50 × 32 | 60.3 × 42.4 | 70 | 70 | / | / |

2″ × 1-1/2″ | 50 × 40 | 60.3 × 48.3 | 70 | 70 | 83 | 83 |

2-1/2″ × 1″ | 65 × 25 | 73.0 × 33.7 | 76 | 76 | 95 | 95 |

2-1/2″ × 1-1/4″ | 65 × 32 | 73.0 × 42.4 | 76 | 76 | 95 | 95 |

2-1/2″ × 1-1/2″ | 65 × 40 | 73.0 × 48.3 | 76 | 76 | 95 | 95 |

2-1/2″ × 2″ | 65 × 50 | 73.0 × 60.3 | 76 | 76 | 95 | 95 |

2-1/2″ × 1″ | 65 × 25 | 76.1 × 33.7 | 76 | 76 | / | / |

2-1/2″ × 1-1/4″ | 65 × 32 | 76.1 × 42.4 | 76 | 76 | / | / |

2-1/2″ × 1-1/2″ | 65 × 40 | 76.1 × 48.3 | 76 | 76 | / | / |

2-1/2″ × 2″ | 65 × 50 | 76.1 × 60.3 | 76 | 76 | / | / |

3″ × 1″ | 80 × 25 | 88.9 × 33.7 | 86 | 86 | 108 | 108 |

3″ × 1-1/4″ | 80 × 32 | 88.9 × 42.4 | 86 | 86 | 108 | 108 |

3″ × 1-1/2″ | 80 × 40 | 88.9 × 48.3 | 86 | 86 | 108 | 108 |

3″ × 2″ | 80 × 50 | 88.9 × 60.3 | 86 | 86 | 108 | 108 |

3″ × 2-1/2″ | 80 × 65 | 88.9 × 73.0 | 86 | 86 | 108 | 108 |

3″ × 2-1/2″ | 80 × 65 | 88.9 × 76.1 | 86 | 86 | / | / |

4″ × 1″ | 100 × 25 | 114.3 × 33.7 | 101 | 101 | 127 | 127 |

4″ × 1-1/2″ | 100 × 40 | 114.3 × 48.3 | 101 | 101 | 127 | 127 |

4″ × 2″ | 100 × 50 | 114.3 × 60.3 | 101 | 101 | 127 | 127 |

4″ × 2-1/2″ | 100 × 65 | 114.3 × 73.0 | 101 | 101 | 127 | 127 |

4″ × 2-1/2″ | 100 × 65 | 114.3 × 76.1 | 101 | 101 | / | / |

4″ × 3″ | 100 × 80 | 114.3 × 88.9 | 101 | 101 | 127 | 127 |

5″ × 1-1/2″ | 125 × 40 | 139.7 × 48.3 | 124 | 124 | / | / |

5″ × 2″ | 125 × 50 | 139.7 × 60.3 | 124 | 124 | / | / |

5″ × 2-1/2″ | 125 × 65 | 139.7 × 76.1 | 124 | 124 | / | / |

5″ × 3″ | 125 × 80 | 139.7 × 88.9 | 124 | 124 | / | / |

5″ × 4″ | 125 × 100 | 139.7 × 114.3 | 124 | 124 | / | / |

5″ × 2″ | 125 × 50 | 141.3 × 60.3 | 124 | 124 | / | / |

5″ × 3″ | 125 × 80 | 141.3 × 88.9 | 124 | 124 | 140 | 140 |

5″ × 4″ | 125 × 100 | 141.3 × 114.3 | 124 | 124 | 140 | 140 |

6″ × 1-1/2″ | 150 × 40 | 165.1 × 48.3 | 140 | 140 | / | / |

6″ × 2″ | 150 × 50 | 165.1 × 60.3 | 140 | 140 | / | / |

6″ × 2-1/2″ | 150 × 65 | 165.1 × 76.1 | 140 | 140 | / | / |

6″ × 3″ | 150 × 80 | 165.1 × 88.9 | 140 | 140 | / | / |

6″ × 4″ | 150 × 100 | 165.1 × 114.3 | 140 | 140 | / | / |

6″ × 5″ | 150 × 125 | 165.1 × 139.7 | 140 | 140 | / | / |

6″ × 1-1/2″ | 150 × 40 | 168.3 × 48.3 | 140 | 140 | / | / |

6″ × 2″ | 150 × 50 | 168.3 × 60.3 | 140 | 140 | 165 | 165 |

6″ × 2-1/2″ | 150 × 65 | 168.3 × 73.0 | 140 | 140 | 165 | 165 |

6″ × 2-1/2″ | 150 × 65 | 168.3 × 76.1 | 140 | 140 | / | / |

6″ × 3″ | 150 × 80 | 168.3 × 88.9 | 140 | 140 | 165 | 165 |

6″ × 4″ | 150 × 100 | 168.3 × 114.3 | 140 | 140 | 165 | 165 |

6″ × 5″ | 150 × 126 | 168.3 × 139.7 | 140 | 140 | / | / |

6″ × 5″ | 150 × 125 | 168.3 × 141.3 | 140 | 140 | 165 | 165 |

8″ × 2″ | 200 × 50 | 219.1 × 60.3 | 175 | 175 | / | / |

8″ × 2-1/2″ | 200 × 65 | 219.1 × 76.1 | 175 | 175 | / | / |

8″ × 3″ | 200 × 80 | 219.1 × 88.9 | 175 | 175 | / | / |

8″ × 4″ | 200 × 100 | 219.1 × 114.3 | 175 | 175 | 197 | 197 |

8″ × 5″ | 200 × 125 | 219.1 × 139.7 | 175 | 175 | / | / |

8″ × 6″ | 200 × 150 | 219.1 × 165.1 | 175 | 175 | / | / |

8″ × 6″ | 200 × 150 | 219.1 × 168.3 | 175 | 175 | 197 | 197 |

10″ × 4″ | 250 × 100 | 273.0 × 114.3 | 215 | 215 | / | / |

10″ × 4″ | 250 × 100 | 273.0 × 114.3 | 229 | 229 | / | / |

10″ × 6″ | 250 × 150 | 273.0 × 165.1 | 229 | 229 | / | / |

10″ × 6″ | 250 × 150 | 273.0 × 168.3 | 229 | 229 | / | / |

10″ × 8″ | 250 × 200 | 273.0 × 219.1 | 229 | 229 | / | / |

12″ × 4″ | 300 × 100 | 323.9 × 114.3 | 254 | 254 | / | / |

12″ × 6″ | 300 × 150 | 323.9 × 165.1 | 254 | 254 | / | / |

12″ × 6″ | 300 × 150 | 323.9 × 168.3 | 254 | 254 | / | / |

12″ × 8″ | 300 × 200 | 323.9 × 219.1 | 254 | 254 | / | / |

12″ × 10″ | 300 × 250 | 323.9 × 273.0 | 254 | 254 | / | / |

14″ × 8″ | 350 × 200 | 355.6 × 219.1 | 280 | 280 | 279 | 279 |

- Used for vertical branch connections in piping systems, it adapts to main pipes and branch pipes of different diameters.

- Suitable for fire protection, HVAC, industrial water supply, and drainage systems.

- It has significant advantages in renovation projects with limited space or requiring quick installation.

1. Flexible adaptation: Both sides of the three end interfaces can be combined into multiple pipe diameters, thereby simplifying the connection between pipes with different diameters.

2. Nickel coated groove: Ease of installation with no welding or specialist tools required = quick and efficient installation!

3. Certified products to ANSI/UL/FM international standards, high pressure resistance with reliability.

4. Facilitative maintenance: Modular design enables local fault repair and lessens need for system-wide repairs.

5. Rust-Resistant and Lasting: Silver painted or hot-dipped galvanized surface, conducive to natural wet corrosion conditions.

- Individual items are wrapped in bubble wrap to prevent scratches and placed securely in pressure-resistant cardboard boxes.

- Large pipe fittings are reinforced with custom wooden boxes and filled with shock-absorbing materials.

- The boxes are labeled with the product model, dimensions, and protective markings to ensure safe transport.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.