HOT PRODUCTS TAGS

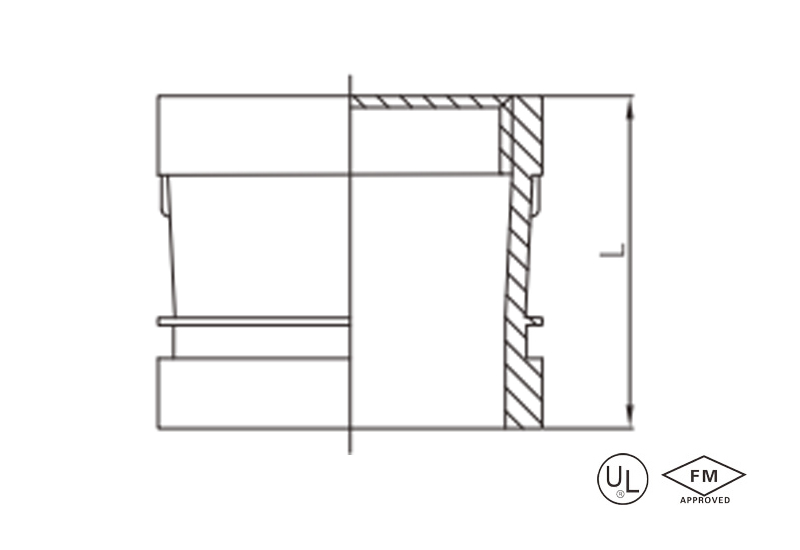

Grooved x female threaded adapter nipple

·Standard: ANSI / UL 213C UL / FM

·Material: Ductile iron ASTM A536, 65-45-12

·Thread run: Female thread, NPT / BSPT

·Rated pressure: 300 – 500 psi

·Surface: Red painting / hot dip galvanized

·Size range: 2” – 4”

description

Grooved x female threaded adapter nipple is a short threaded adapter with a grooved connection structure at one end and an internal thread at the other end, used for the transitional connection between the grooved connection and the internal thread connection

Specification

Available size

Size | End to end | ||

Inch | DN | mm | L(mm) |

2″ | 50 | 60.3 | 64 |

2-1/2″ | 65 | 73.0 | 70 |

3″ | 80 | 88.9 | 70 |

4″ | 100 | 114.3 | 83 |

application

- Interface Conversion Connection: Enables quick transition connections between groove pipe systems and internal thread valves, instruments, and equipment.

- Fire Protection/HVAC Systems: Connections between groove main pipes and threaded branch pipes in fire sprinkler systems and HVAC water systems.

- Equipment Installation: Expanding existing groove pipe systems with pressure gauges, sensors, and other monitoring devices featuring external threads.

- Repair and Replacement: Replacing damaged pipe ends while maintaining compatibility with groove clamps and threaded components, thereby reducing renovation costs.

advantages

- Seamless interface conversion: One piece of clothes can achieve the connection of groove end clamp and internal thread end (NPT/BSPT standard) screw without adapter.

- Efficient installation: Lock the groove end with clamp in seconds, and may rotate the threaded end manually, 70% time saved without any special tools.

- Ductile iron construction enables high strength and impact resistance, while the hot-dip galvanized/red paint coating results in corrosion prevention — together this makes for a lifetime more than 15 years.

- Pressure safety higher: UL/ FM Certified, no leakage at pressure 300~500 PSI

- Compatible with NPT and BSPT thread standards, which are globally adaptable to equipment in North America, Europe and Asia

packing

- Individual items are protected with a rust-proof oil coating and wrapped in cushioning film to prevent scratches and moisture damage during transportation.

- Standard packaging consists of a corrugated cardboard box with EPE foam inserts for product positioning. The box includes a product label (with dimensions and thread type), a certificate of conformity, and a warranty card.

- The outer box is clearly printed with the product name, specifications (e.g., 2“ NPT), quantity, weight, and certification marks (UL/FM), and marked with ”This Side Up“ and ”Keep Dry” icons.

- For 4-inch specifications, thickened cardboard boxes with corner protectors are provided, and custom wooden boxes are available upon request (additional charges apply).

- All packaging meets the ISTA 3E export transportation testing standards.

Available size

Size | End to end | ||

Inch | DN | mm | L(mm) |

2″ | 50 | 60.3 | 64 |

2-1/2″ | 65 | 73.0 | 70 |

3″ | 80 | 88.9 | 70 |

4″ | 100 | 114.3 | 83 |

- Interface Conversion Connection: Enables quick transition connections between groove pipe systems and internal thread valves, instruments, and equipment.

- Fire Protection/HVAC Systems: Connections between groove main pipes and threaded branch pipes in fire sprinkler systems and HVAC water systems.

- Equipment Installation: Expanding existing groove pipe systems with pressure gauges, sensors, and other monitoring devices featuring external threads.

- Repair and Replacement: Replacing damaged pipe ends while maintaining compatibility with groove clamps and threaded components, thereby reducing renovation costs.

- Seamless interface conversion: One piece of clothes can achieve the connection of groove end clamp and internal thread end (NPT/BSPT standard) screw without adapter.

- Efficient installation: Lock the groove end with clamp in seconds, and may rotate the threaded end manually, 70% time saved without any special tools.

- Ductile iron construction enables high strength and impact resistance, while the hot-dip galvanized/red paint coating results in corrosion prevention — together this makes for a lifetime more than 15 years.

- Pressure safety higher: UL/ FM Certified, no leakage at pressure 300~500 PSI

- Compatible with NPT and BSPT thread standards, which are globally adaptable to equipment in North America, Europe and Asia

- Individual items are protected with a rust-proof oil coating and wrapped in cushioning film to prevent scratches and moisture damage during transportation.

- Standard packaging consists of a corrugated cardboard box with EPE foam inserts for product positioning. The box includes a product label (with dimensions and thread type), a certificate of conformity, and a warranty card.

- The outer box is clearly printed with the product name, specifications (e.g., 2“ NPT), quantity, weight, and certification marks (UL/FM), and marked with ”This Side Up“ and ”Keep Dry” icons.

- For 4-inch specifications, thickened cardboard boxes with corner protectors are provided, and custom wooden boxes are available upon request (additional charges apply).

- All packaging meets the ISTA 3E export transportation testing standards.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.