HOT PRODUCTS TAGS

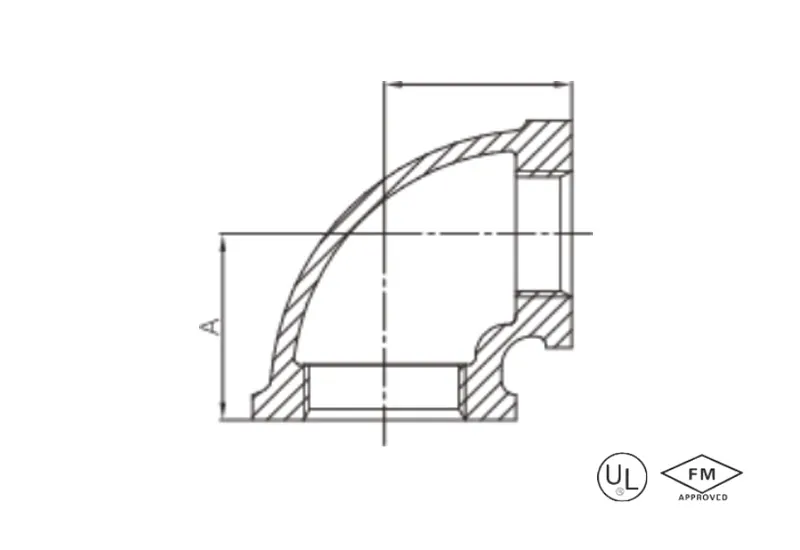

Malleable cast iron 90° reducing elbow

·Standard: ISO 49 / EN 10242

UL/FM

·Material: BS EN 1562, EN-GJMB-350-10

·Thread: BSPT

·W. pressure: 20 ~ 25 bar, ≤ PN25

·Surface: Black iron / hot dip galvanized

·Size Range: 1/2″ x 3/8″–6″ x 4″

description

Malleable cast iron 90° reducing elbow, for pipe diameter change and redirection, suitable for multiple scenarios.

Specification

Available size

SIZE | A | B | ||

INCH | DN | MM | MM | MM |

1/2″ x 3/8″ | 15 x 10 | 21.3 x 17.2 | 26 | 26 |

3/4″ x 3/8″ | 20 x 10 | 26.9 x 17.2 | 28 | 28 |

3/4″ x 1/2″ | 20 x 15 | 26.9 x 21.3 | 30 | 31 |

1″ x 3/8″ | 25 x 10 | 33.7 x 17.2 | 30 | 32 |

1″ x 1/2″ | 25 x 15 | 33.7 x 21.3 | 32 | 34 |

1″ x 3/4″ | 25 x 20 | 33.7 x 26.9 | 35 | 36 |

1-1/4″ x 3/8″ | 32 x 10 | 42.4 x 17.2 | 32 | 36.5 |

1-1/4″ x 1/2″ | 32 x 15 | 42.4 x 21.3 | 32 | 37 |

1-1/4″ x 3/4″ | 32 x 20 | 42.4 x 26.9 | 36 | 41 |

1-1/4″ x 1″ | 32 x 25 | 42.4 x 33.7 | 40 | 42 |

1-1/2″ x 1/2″ | 40 x 15 | 48.3 x 21.3 | 34 | 41 |

1-1/2″ x 3/4″ | 40 x 20 | 48.3 x 26.9 | 37 | 42 |

1-1/2″ x 1″ | 40 x 25 | 48.3 x 33.7 | 42 | 46 |

1-1/2″ x 1-1/4″ | 40 x 32 | 48.3 x 42.4 | 46 | 48 |

2″ x 1/2″ | 50 x 15 | 60.3 x 21.3 | 35 | 47 |

2″ x 3/4″ | 50 x 20 | 60.3 x 26.9 | 40 | 48 |

2″ x 1″ | 50 x 25 | 60.3 x 33.7 | 43 | 50 |

2″ x 1-1/4″ | 50 x 32 | 60.3 x 42.4 | 47 | 53 |

2″ x 1-1/2″ | 50 x 40 | 60.3 x 48.3 | 52 | 56 |

2-1/2″ x 1/2″ | 65 x 15 | 76.1 x 21.3 | 40 | 56 |

2-1/2″ x 3/4″ | 65 x 20 | 76.1 x 26.9 | 42.5 | 57 |

2-1/2″ x 1″ | 65 x 25 | 76.1 x 33.7 | 46.5 | 58.5 |

2-1/2″ x 1-1/4″ | 65 x 32 | 76.1 x 42.4 | 50.5 | 60 |

2-1/2″ x 1-1/2″ | 65 x 40 | 76.1 x 48.3 | 53.5 | 61 |

2-1/2″ x 2″ | 65 x 50 | 76.1 x 60.3 | 61 | 66 |

3″ x 1/2″ | 80 x 15 | 88.9 x 21.3 | 43 | 64 |

3″ x 3/4″ | 80 x 20 | 88.9 x 26.9 | 45 | 65 |

3″ x 1″ | 80 x 25 | 88.9 x 33.7 | 50 | 68 |

3″ x 1-1/4″ | 80 x 32 | 88.9 x 42.4 | 53.5 | 68 |

3″ x 1-1/2″ | 80 x 40 | 88.9 x 48.3 | 56 | 69 |

3″ x 2″ | 80 x 50 | 88.9 x 60.3 | 60.5 | 71 |

3″ x 2-1/2″ | 80 x 65 | 88.9 x 76.1 | 71 | 74 |

4″ x 1/2″ | 100 x 15 | 114.3 x 21.3 | 54 | 70 |

4″ x 3/4″ | 100 x 20 | 114.3 x 26.9 | 56 | 74 |

4″ x 1″ | 100 x 25 | 114.3 x 33.7 | 58 | 76 |

4″ x 1-1/4″ | 100 x 32 | 114.3 x 42.4 | 60 | 80 |

4″ x 1-1/2″ | 100 x 40 | 114.3 x 48.3 | 62 | 85 |

4″ x 2″ | 100 x 50 | 114.3 x 60.3 | 68 | 86 |

4″ x 2-1/2″ | 100 x 65 | 114.3 x 76.1 | 77 | 89 |

4″ x 3″ | 100 x 80 | 114.3 x 88.9 | 82 | 90 |

6″ x 4″ | 150 x 100 | 165.1 x 114.3 | 102 | 125 |

Note: NSF 61 certificate is available for M0206 ~ M0253, except M0209, M0215, M0254.

application

- Building Plumbing Systems: Right-angle turns and diameter transitions for vertical and horizontal pipes.

- Fire Protection System Upgrades: UL/FM-certified safety turns for high-pressure diameter transitions in sprinkler systems.

- HVAC Engineering: Compact right-angle diameter transitions between chilled water mains and terminal equipment.

- Industrial Fluid Conveyance: Pressure-resistant diameter transitions for steam/compressed air pipes.

- Municipal Water Supply Network: 90° diameter transition space optimization layout between main and branch pipes.

- Outdoor Exposed Piping: Hot-dip galvanized surfaces resisting corrosion from wind and rain.

- Energy Transportation Hub: Right-angle diameter transition connections between oil and gas pipeline segments of different specifications.

- Ship Engine Room Piping: Pipe turns and diameter transitions achieved in confined spaces.

advantages

- Dual-function integrated design: Single-piece design enables simultaneous 90° turning and pipe diameter conversion.

- High-pressure sealing assurance: Zero leakage operation under 25 bar working pressure with BSPT tapered threads.

- Full environmental corrosion resistance: Hot-dip galvanized coating resists corrosion from moisture and weak chemical media.

- Wide temperature range stability: Maintains material strength and seal integrity from -30°C to 120°C.

- Dual international certifications: Certified for UL/FM fire safety and NSF 61 drinking water standards (applicable to models M0206 to M0253).

- Optimized fluid efficiency: Smooth inner wall channels reduce pressure loss and turbulence noise.

- Lifetime durability guarantee: Forged cast iron base enhances impact resistance by three times.

- Compact space adaptation: Right-angle structure saves 30% installation space for optimized layout.

packing

- Curved Surface Protective Pad: Custom PE foam fully wraps the 90° curved corner for collision protection.

- Different Diameter End Protection: Dual-diameter injection-molded threaded covers match the port specifications.

- Shock-Absorbing Full Coverage: Bubble column bags wrap the surface to prevent transportation scratches and damage.

- Size-Specific Positioning: Honeycomb cardboard compartments are categorized by size to secure and prevent shifting.

- Dual-color flow direction indicators: Outer boxes printed with installation flow direction arrows and diameter change direction indicators.

- Load-bearing graded packaging: ≤2“ uses five-layer corrugated boxes / ≥2.5” uses steel-edged wooden boxes.

- Full-process traceability management: Laser-engraved batch numbers + smart QR codes for traceability.

- Anti-rolling structural design: Concave grooves inside the box lock the elbow in place during transportation to prevent displacement.

Available size

SIZE | A | B | ||

INCH | DN | MM | MM | MM |

1/2″ x 3/8″ | 15 x 10 | 21.3 x 17.2 | 26 | 26 |

3/4″ x 3/8″ | 20 x 10 | 26.9 x 17.2 | 28 | 28 |

3/4″ x 1/2″ | 20 x 15 | 26.9 x 21.3 | 30 | 31 |

1″ x 3/8″ | 25 x 10 | 33.7 x 17.2 | 30 | 32 |

1″ x 1/2″ | 25 x 15 | 33.7 x 21.3 | 32 | 34 |

1″ x 3/4″ | 25 x 20 | 33.7 x 26.9 | 35 | 36 |

1-1/4″ x 3/8″ | 32 x 10 | 42.4 x 17.2 | 32 | 36.5 |

1-1/4″ x 1/2″ | 32 x 15 | 42.4 x 21.3 | 32 | 37 |

1-1/4″ x 3/4″ | 32 x 20 | 42.4 x 26.9 | 36 | 41 |

1-1/4″ x 1″ | 32 x 25 | 42.4 x 33.7 | 40 | 42 |

1-1/2″ x 1/2″ | 40 x 15 | 48.3 x 21.3 | 34 | 41 |

1-1/2″ x 3/4″ | 40 x 20 | 48.3 x 26.9 | 37 | 42 |

1-1/2″ x 1″ | 40 x 25 | 48.3 x 33.7 | 42 | 46 |

1-1/2″ x 1-1/4″ | 40 x 32 | 48.3 x 42.4 | 46 | 48 |

2″ x 1/2″ | 50 x 15 | 60.3 x 21.3 | 35 | 47 |

2″ x 3/4″ | 50 x 20 | 60.3 x 26.9 | 40 | 48 |

2″ x 1″ | 50 x 25 | 60.3 x 33.7 | 43 | 50 |

2″ x 1-1/4″ | 50 x 32 | 60.3 x 42.4 | 47 | 53 |

2″ x 1-1/2″ | 50 x 40 | 60.3 x 48.3 | 52 | 56 |

2-1/2″ x 1/2″ | 65 x 15 | 76.1 x 21.3 | 40 | 56 |

2-1/2″ x 3/4″ | 65 x 20 | 76.1 x 26.9 | 42.5 | 57 |

2-1/2″ x 1″ | 65 x 25 | 76.1 x 33.7 | 46.5 | 58.5 |

2-1/2″ x 1-1/4″ | 65 x 32 | 76.1 x 42.4 | 50.5 | 60 |

2-1/2″ x 1-1/2″ | 65 x 40 | 76.1 x 48.3 | 53.5 | 61 |

2-1/2″ x 2″ | 65 x 50 | 76.1 x 60.3 | 61 | 66 |

3″ x 1/2″ | 80 x 15 | 88.9 x 21.3 | 43 | 64 |

3″ x 3/4″ | 80 x 20 | 88.9 x 26.9 | 45 | 65 |

3″ x 1″ | 80 x 25 | 88.9 x 33.7 | 50 | 68 |

3″ x 1-1/4″ | 80 x 32 | 88.9 x 42.4 | 53.5 | 68 |

3″ x 1-1/2″ | 80 x 40 | 88.9 x 48.3 | 56 | 69 |

3″ x 2″ | 80 x 50 | 88.9 x 60.3 | 60.5 | 71 |

3″ x 2-1/2″ | 80 x 65 | 88.9 x 76.1 | 71 | 74 |

4″ x 1/2″ | 100 x 15 | 114.3 x 21.3 | 54 | 70 |

4″ x 3/4″ | 100 x 20 | 114.3 x 26.9 | 56 | 74 |

4″ x 1″ | 100 x 25 | 114.3 x 33.7 | 58 | 76 |

4″ x 1-1/4″ | 100 x 32 | 114.3 x 42.4 | 60 | 80 |

4″ x 1-1/2″ | 100 x 40 | 114.3 x 48.3 | 62 | 85 |

4″ x 2″ | 100 x 50 | 114.3 x 60.3 | 68 | 86 |

4″ x 2-1/2″ | 100 x 65 | 114.3 x 76.1 | 77 | 89 |

4″ x 3″ | 100 x 80 | 114.3 x 88.9 | 82 | 90 |

6″ x 4″ | 150 x 100 | 165.1 x 114.3 | 102 | 125 |

Note: NSF 61 certificate is available for M0206 ~ M0253, except M0209, M0215, M0254.

- Building Plumbing Systems: Right-angle turns and diameter transitions for vertical and horizontal pipes.

- Fire Protection System Upgrades: UL/FM-certified safety turns for high-pressure diameter transitions in sprinkler systems.

- HVAC Engineering: Compact right-angle diameter transitions between chilled water mains and terminal equipment.

- Industrial Fluid Conveyance: Pressure-resistant diameter transitions for steam/compressed air pipes.

- Municipal Water Supply Network: 90° diameter transition space optimization layout between main and branch pipes.

- Outdoor Exposed Piping: Hot-dip galvanized surfaces resisting corrosion from wind and rain.

- Energy Transportation Hub: Right-angle diameter transition connections between oil and gas pipeline segments of different specifications.

- Ship Engine Room Piping: Pipe turns and diameter transitions achieved in confined spaces.

- Dual-function integrated design: Single-piece design enables simultaneous 90° turning and pipe diameter conversion.

- High-pressure sealing assurance: Zero leakage operation under 25 bar working pressure with BSPT tapered threads.

- Full environmental corrosion resistance: Hot-dip galvanized coating resists corrosion from moisture and weak chemical media.

- Wide temperature range stability: Maintains material strength and seal integrity from -30°C to 120°C.

- Dual international certifications: Certified for UL/FM fire safety and NSF 61 drinking water standards (applicable to models M0206 to M0253).

- Optimized fluid efficiency: Smooth inner wall channels reduce pressure loss and turbulence noise.

- Lifetime durability guarantee: Forged cast iron base enhances impact resistance by three times.

- Compact space adaptation: Right-angle structure saves 30% installation space for optimized layout.

- Curved Surface Protective Pad: Custom PE foam fully wraps the 90° curved corner for collision protection.

- Different Diameter End Protection: Dual-diameter injection-molded threaded covers match the port specifications.

- Shock-Absorbing Full Coverage: Bubble column bags wrap the surface to prevent transportation scratches and damage.

- Size-Specific Positioning: Honeycomb cardboard compartments are categorized by size to secure and prevent shifting.

- Dual-color flow direction indicators: Outer boxes printed with installation flow direction arrows and diameter change direction indicators.

- Load-bearing graded packaging: ≤2“ uses five-layer corrugated boxes / ≥2.5” uses steel-edged wooden boxes.

- Full-process traceability management: Laser-engraved batch numbers + smart QR codes for traceability.

- Anti-rolling structural design: Concave grooves inside the box lock the elbow in place during transportation to prevent displacement.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.