HOT PRODUCTS TAGS

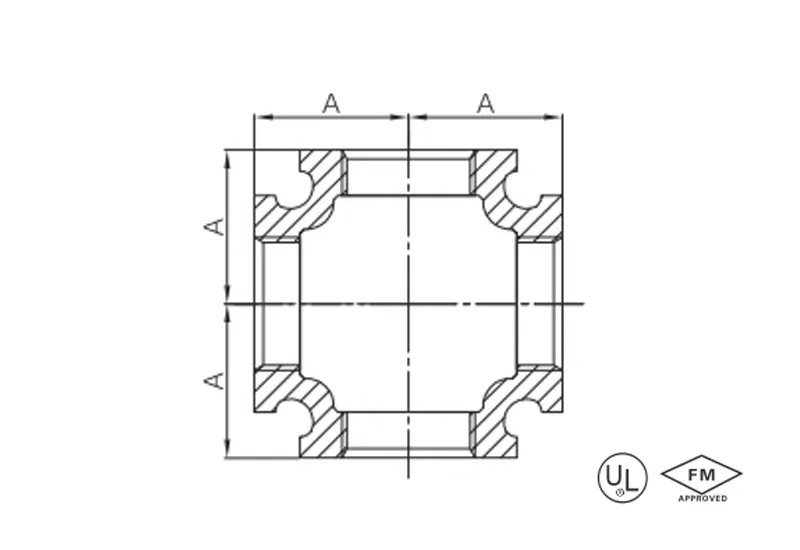

Malleable iron straight cross

·Standard: ANSI/ASME B16.3

UL/FM

·Material: Malleable iron ASTM A197

·Thread: NPT

·W. pressure: Class 150, 300 psi (-29°C to 66°C)

·Surface: Black iron / hot dip galvanized

·Size Range: 1/2″ —4″ (Class 150)

description

Malleable iron straight cross offers strong four-way connectivity, even flow distribution, pressure and corrosion resistance, and easy installation.

Specification

Available size

SIZE | A | ||

INCH | DN | MM | MM |

1/2″ | 15 | 21.3 | 28.5 |

3/4″ | 20 | 26.7 | 33.3 |

1″ | 25 | 33.4 | 38.1 |

1-1/4″ | 32 | 42.2 | 44.5 |

1-1/2″ | 40 | 48.3 | 49.3 |

2″ | 50 | 60.3 | 57.2 |

2-1/2″ | 65 | 73 | 68.6 |

3″ | 80 | 88.9 | 78.2 |

4″ | 100 | 114.3 | 96.3 |

application

- Central air conditioning main pipeline network: Four-way balanced distribution of chilled water to terminal units in each area.

- Industrial circulating cooling system: Synchronous connection of multiple heat exchange devices to achieve uniform flow temperature control.

- Fire sprinkler core hub: Cross-flow distribution ensures full coverage of fire extinguishing across multiple areas of the building.

- Chemical multi-reactor feeding: Stable delivery of raw materials to a cluster of parallel reaction devices.

- Ship Integrated Piping System: Balances the distribution of ballast water to the four-way compartment pipelines.

- Regional Heating Transmission Hub: Uniformly distributes thermal energy to the secondary heating network.

- Data Center Cooling Main Trunk: Efficiently distributes coolant to server cabinet clusters.

advantages

- Balanced Crossflow: Flow surfaces are optimized for maximum effluent quality with equal flow pressure at each outlet.

- Comprehensive anti-corrosion: external and inner layer of duct is coated with imported hot-dip galvanized sheet, which can resist the corrosion of chemical media.

- Zero leak sealing: precision threaded connections assure a long-term seal.

- Certified explosion-proof: tested to dual international standards for use in hazardous areas

- A wide range of temperature adaptability: Stable performance under very hot or cold climate.

- Fast modular installation: standardized interfaces make multi-pipe connections easy.

- Longer product life: Highly efficient manufacturing methods result in lower maintenance costs.

packing

- Single-unit 3D protection: Custom EPS coating protects the four-way pipe body from collisions.

- Threaded omnidirectional protective cover: Special screw cap protects the four-way threaded interface.

- Layered earthquake-resistant packaging: Honeycomb cardboard dividers secure and prevent shifting.

- Waterproof outer box labeling: Printed flow direction arrows and moisture-proof stacking marks.

- Heavy-duty export wooden boxes: Steel band matrix strapping enhances compression strength.

- Strict transportation testing: Complies with international logistics safety certification standards.

- Full-process traceability system: Dual information traceability for pipe bodies and packaging.

Available size

SIZE | A | ||

INCH | DN | MM | MM |

1/2″ | 15 | 21.3 | 28.5 |

3/4″ | 20 | 26.7 | 33.3 |

1″ | 25 | 33.4 | 38.1 |

1-1/4″ | 32 | 42.2 | 44.5 |

1-1/2″ | 40 | 48.3 | 49.3 |

2″ | 50 | 60.3 | 57.2 |

2-1/2″ | 65 | 73 | 68.6 |

3″ | 80 | 88.9 | 78.2 |

4″ | 100 | 114.3 | 96.3 |

- Central air conditioning main pipeline network: Four-way balanced distribution of chilled water to terminal units in each area.

- Industrial circulating cooling system: Synchronous connection of multiple heat exchange devices to achieve uniform flow temperature control.

- Fire sprinkler core hub: Cross-flow distribution ensures full coverage of fire extinguishing across multiple areas of the building.

- Chemical multi-reactor feeding: Stable delivery of raw materials to a cluster of parallel reaction devices.

- Ship Integrated Piping System: Balances the distribution of ballast water to the four-way compartment pipelines.

- Regional Heating Transmission Hub: Uniformly distributes thermal energy to the secondary heating network.

- Data Center Cooling Main Trunk: Efficiently distributes coolant to server cabinet clusters.

- Balanced Crossflow: Flow surfaces are optimized for maximum effluent quality with equal flow pressure at each outlet.

- Comprehensive anti-corrosion: external and inner layer of duct is coated with imported hot-dip galvanized sheet, which can resist the corrosion of chemical media.

- Zero leak sealing: precision threaded connections assure a long-term seal.

- Certified explosion-proof: tested to dual international standards for use in hazardous areas

- A wide range of temperature adaptability: Stable performance under very hot or cold climate.

- Fast modular installation: standardized interfaces make multi-pipe connections easy.

- Longer product life: Highly efficient manufacturing methods result in lower maintenance costs.

- Single-unit 3D protection: Custom EPS coating protects the four-way pipe body from collisions.

- Threaded omnidirectional protective cover: Special screw cap protects the four-way threaded interface.

- Layered earthquake-resistant packaging: Honeycomb cardboard dividers secure and prevent shifting.

- Waterproof outer box labeling: Printed flow direction arrows and moisture-proof stacking marks.

- Heavy-duty export wooden boxes: Steel band matrix strapping enhances compression strength.

- Strict transportation testing: Complies with international logistics safety certification standards.

- Full-process traceability system: Dual information traceability for pipe bodies and packaging.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.