HOT PRODUCTS TAGS

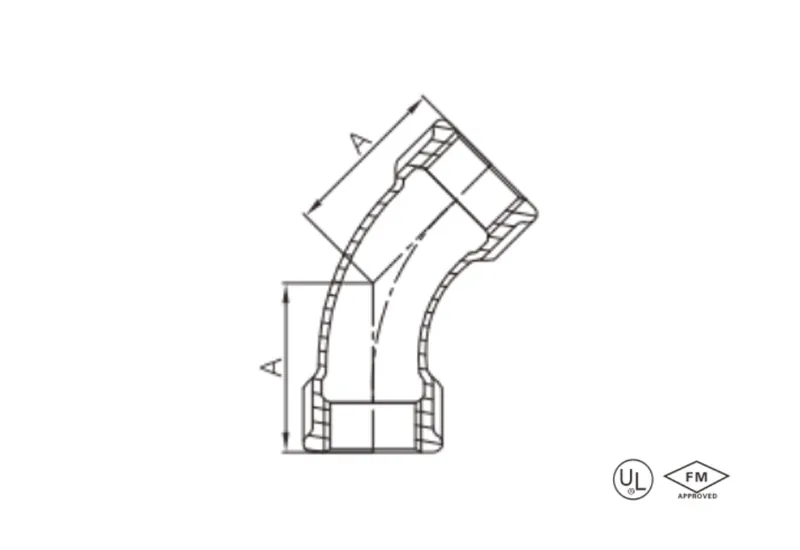

Malleable cast iron 45° long sweep bend

·Standard: ISO 49 / EN 10242

UL/FM

·Material: BS EN 1562, EN-GJMB-350-10

·Thread: BSPT

·W. pressure: 20 ~ 25 bar, ≤ PN25

·Surface: Black iron / hot dip galvanized

·Size Range: 1/4″ —4″

description

Malleable cast iron 45° long sweep bend, gentle arc guides flow and reduces resistance, sturdy, corrosion-resistant, fits complex pipelines.

Specification

Available size

SIZE | A | ||

INCH | DN | MM | MM |

1/4″ | 8 | 13.5 | 26 |

3/8″ | 10 | 17.2 | 30 |

1/2″ | 15 | 21.3 | 36 |

3/4″ | 20 | 26.9 | 43 |

1″ | 25 | 33.7 | 51 |

1-1/4″ | 32 | 42.4 | 64 |

1-1/2″ | 40 | 48.3 | 68 |

2″ | 50 | 60.3 | 81 |

2-1/2″ | 65 | 76.1 | 99 |

3″ | 80 | 88.9 | 113 |

4″ | 100 | 114.3 | 142 |

application

- Chemical process systems: 45° long-radius elbows enable smooth turns for high-viscosity media.

- Fire protection network layout: UL-certified structures ensure low flow resistance angle adjustments for sprinkler systems.

- Ship power piping: Smooth angle transitions for fuel/cooling water systems in engine rooms.

- Energy transmission networks: Gradual angle transitions for oil and gas pipelines reduce pressure loss.

- Municipal water supply renovation: Gentle angle transitions for main road networks reduce water hammer effects.

- Industrial Equipment Integration: Space-optimized angle transitions for compressor inlet/outlet pipelines.

- Agricultural Irrigation Systems: Water-saving angle adjustment solutions for pump station main pipelines.

- Mining Slurry Conveyance: High wear-resistant properties for angle transitions in slurry pipelines.

advantages

- Optimized fluid dynamics: 45° long radius results in the least amount of flow resistance when turning.

- Pressure Capacity: To satisfy the demands of industrial plumbing systems.

- Proven wear resistance: Base material tested in industrial wear.

- Durable corrosion protection system: Zinc plated finish offers full corrosion defense Ease to Install: Seals are quick by BSPT threads.

- Resistance to High Stresses: Low-radius bend minimizes potential for stress concentration.

- Maneuverable in tight spaces: 45° Steering angle for optimum complex Aerobic spatial layouts.

- Rich Specifications: DN8-DN100 Across a Wide Range of Pipelines.

packing

- Thread protection system: Plastic screw cap protection nested from both sides.

- Curved Surface Cushioning Design: EPE pearl cotton wrapped with flexural bending pipe.

- Corrosion Protection: Vapor phase corrosion inhibitor (VCI) vacuum sealing.

- An Imprinted Identification Management System : symbols at 45° on the outer box and elbow markers.

- Anti-displacement design :Inner box angle fixation frame, which guaranteed transportation stability.

Available size

SIZE | A | ||

INCH | DN | MM | MM |

1/4″ | 8 | 13.5 | 26 |

3/8″ | 10 | 17.2 | 30 |

1/2″ | 15 | 21.3 | 36 |

3/4″ | 20 | 26.9 | 43 |

1″ | 25 | 33.7 | 51 |

1-1/4″ | 32 | 42.4 | 64 |

1-1/2″ | 40 | 48.3 | 68 |

2″ | 50 | 60.3 | 81 |

2-1/2″ | 65 | 76.1 | 99 |

3″ | 80 | 88.9 | 113 |

4″ | 100 | 114.3 | 142 |

- Chemical process systems: 45° long-radius elbows enable smooth turns for high-viscosity media.

- Fire protection network layout: UL-certified structures ensure low flow resistance angle adjustments for sprinkler systems.

- Ship power piping: Smooth angle transitions for fuel/cooling water systems in engine rooms.

- Energy transmission networks: Gradual angle transitions for oil and gas pipelines reduce pressure loss.

- Municipal water supply renovation: Gentle angle transitions for main road networks reduce water hammer effects.

- Industrial Equipment Integration: Space-optimized angle transitions for compressor inlet/outlet pipelines.

- Agricultural Irrigation Systems: Water-saving angle adjustment solutions for pump station main pipelines.

- Mining Slurry Conveyance: High wear-resistant properties for angle transitions in slurry pipelines.

- Optimized fluid dynamics: 45° long radius results in the least amount of flow resistance when turning.

- Pressure Capacity: To satisfy the demands of industrial plumbing systems.

- Proven wear resistance: Base material tested in industrial wear.

- Durable corrosion protection system: Zinc plated finish offers full corrosion defense Ease to Install: Seals are quick by BSPT threads.

- Resistance to High Stresses: Low-radius bend minimizes potential for stress concentration.

- Maneuverable in tight spaces: 45° Steering angle for optimum complex Aerobic spatial layouts.

- Rich Specifications: DN8-DN100 Across a Wide Range of Pipelines.

- Thread protection system: Plastic screw cap protection nested from both sides.

- Curved Surface Cushioning Design: EPE pearl cotton wrapped with flexural bending pipe.

- Corrosion Protection: Vapor phase corrosion inhibitor (VCI) vacuum sealing.

- An Imprinted Identification Management System : symbols at 45° on the outer box and elbow markers.

- Anti-displacement design :Inner box angle fixation frame, which guaranteed transportation stability.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.