ГОРЯЧИЕ ТЕГИ ПРОДУКТОВ

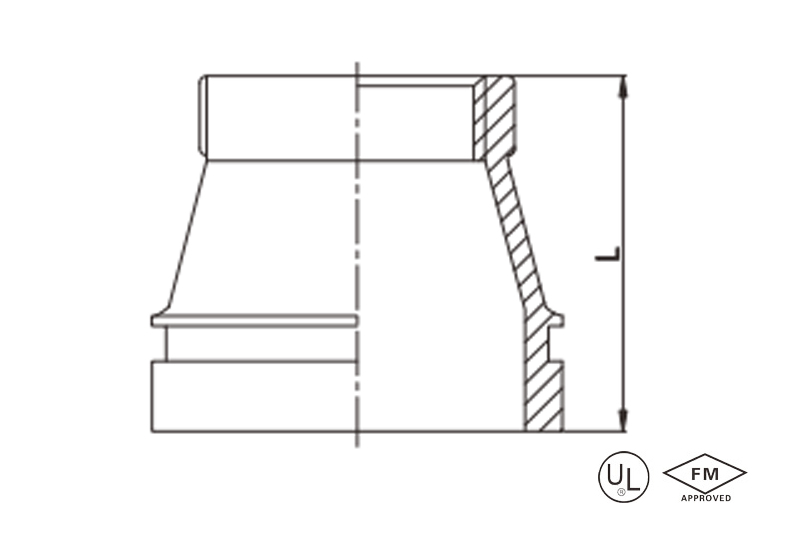

Концентрический редуктор с канавкой и внутренней резьбой на выходе

-Стандарт: ANSI / UL 213C UL / FM

-Материал: Ковкий чугун ASTM A536, 65-45-12

-Поток: Внутренняя резьба, NPT / BSPT

-Номинальное давление: 300 - 500 фунтов на кв. дюйм

-Поверхность: Красная окраска / горячая гальванизация

-Размерный ряд: 1-1/2”×1” - 8″×4″

описание

Концентрический редуктор с желобком и внутренней резьбой на выходе - это концентрический редуктор с разными диаметрами труб на обоих концах и перекрывающимися осевыми линиями. Выходной конец имеет внутреннюю резьбу и используется для соединения труб разного диаметра и адаптации к компонентам с внутренней резьбой

Технические характеристики

Доступный размер

Размер | От конца до конца | ||

Дюйм | DN | мм | L (мм) |

1-1/2” × 1” | 40 × 25 | 48.3 × 33.7 | 64 |

2″ × 1/2″ | 50 × 15 | 60.3 × 21.3 | 64 |

2″ × 3/4″ | 50 × 20 | 60.3 × 26.9 | 64 |

2″ × 1″ | 50 × 25 | 60.3 × 33.7 | 64 |

2″ × 1-1/4″ | 50 × 32 | 60.3 × 42.4 | 64 |

2″ × 1-1/2″ | 50 × 40 | 60.3 × 48.3 | 64 |

2-1/2″ × 1″ | 65 × 25 | 73.0 × 33.7 | 64 |

2-1/2″ × 1-1/4″ | 65 × 32 | 73.0 × 42.4 | 64 |

2-1/2″ × 1-1/2″ | 65 × 40 | 73.0 × 48.3 | 64 |

2-1/2″ × 2″ | 65 × 50 | 73.0 × 60.3 | 64 |

2-1/2″ × 1/2″ | 65 × 15 | 76.1 × 21.3 | 64 |

2-1/2″ × 3/4″ | 65 × 20 | 76.1 × 26.9 | 64 |

2-1/2″ × 1″ | 65 × 25 | 76.1 × 33.7 | 64 |

2-1/2″ × 1-1/4″ | 65 × 32 | 76.1 × 42.4 | 64 |

2-1/2″ × 1-1/2″ | 65 × 40 | 76.1 × 48.3 | 64 |

2-1/2″ × 2″ | 65 × 50 | 76.1 × 60.3 | 64 |

3″ × 1″ | 80 × 25 | 88.9 × 33.7 | 64 |

3″ × 1-1/4″ | 80 × 32 | 88.9 × 42.4 | 64 |

3″ × 1-1/2″ | 80 × 40 | 88.9 × 48.3 | 64 |

3″ × 2″ | 80 × 50 | 88.9 × 60.3 | 64 |

3″ × 2-1/2″ | 80 × 65 | 88.9 × 73.0 | 64 |

3″ × 2-1/2″ | 80 × 65 | 88.9 × 76.1 | 64 |

4″ × 1″ | 100 × 25 | 114.3 × 33.7 | 76 |

4″ × 1-1/4″ | 100 × 32 | 114.3 × 42.4 | 76 |

4″ × 1-1/2″ | 100 × 40 | 114.3 × 48.3 | 76 |

4″ × 2″ | 100 × 50 | 114.3 × 60.3 | 76 |

4″ × 2-1/2″ | 100 × 65 | 114.3 × 73.0 | 76 |

4″ × 2-1/2″ | 100 × 65 | 114.3 × 76.1 | 76 |

4″ × 3″ | 100 × 80 | 114.3 × 88.9 | 76 |

5″ × 1″ | 125 × 25 | 139.7 × 33.7 | 89 |

5″ × 1-1/4″ | 125 × 32 | 139.7 × 42.4 | 89 |

5″ × 1-1/2″ | 125 × 40 | 139.7 × 48.3 | 89 |

5″ × 2″ | 125 × 50 | 139.7 × 60.3 | 89 |

5″ × 2-1/2″ | 125 × 65 | 139.7 × 76.1 | 89 |

5″ × 3″ | 125 × 80 | 139.7 × 88.9 | 89 |

5″ × 4″ | 125 × 100 | 139.7 × 114.3 | 89 |

6″ × 1″ | 150 × 25 | 165.1 × 33.7 | 102 |

6″ × 1-1/4″ | 150 × 32 | 165.1 × 42.4 | 102 |

6″ × 1-1/2″ | 150 × 40 | 165.1 × 48.3 | 102 |

6″ × 2″ | 150 × 50 | 165.1 × 60.3 | 102 |

6″ × 2-1/2″ | 150 × 65 | 165.1 × 76.1 | 102 |

6″ × 3″ | 150 × 80 | 165.1 × 88.9 | 102 |

6″ × 4″ | 150 × 100 | 165.1 × 114.3 | 102 |

6″ × 1″ | 150 × 25 | 168.3 × 33.7 | 102 |

6″ × 2″ | 150 × 50 | 168.3 × 60.3 | 102 |

6″ × 3″ | 150 × 80 | 168.3 × 88.9 | 102 |

6″ × 4″ | 150 × 100 | 168.3 × 114.3 | 102 |

8″ × 1-1/2″ | 200 × 40 | 219.1 × 48.3 | 127 |

6″ × 4″ | 150 × 100 | 168.3 × 114.3 | 102 |

8″ × 1-1/2″ | 200 × 40 | 219.1 × 48.3 | 127 |

8″ × 2″ | 200 × 50 | 219.1 × 60.3 | 127 |

8″ × 2-1/2″ | 200 × 65 | 219.1 × 76.1 | 127 |

8″ × 3″ | 200 × 80 | 219.1 × 88.9 | 127 |

8″ × 4″ | 200 × 100 | 219.1 × 114.3 | 127 |

приложение

- Обновление интеграции оборудования: Специально разработанные для систем, требующих одновременного изменения диаметра труб и подключения оборудования, ответвления с внутренней резьбой напрямую подключаются к таким приборам, как манометры и предохранительные клапаны, что подходит для таких ответственных узлов, как насосные станции и энергетические установки.

- Компактная оптимизация пространства: Концентрическая структура изменения диаметра экономит монтажное пространство, подходит для узких мест, таких как трубные колодцы и слои оборудования, предотвращая риски утечки, вызванные несколькими адаптерами.

- Прецизионный контроль жидкости: Это решение, разработанное для малорасходных ответвлений в системах ОВКВ и водоподготовки, требующих мониторинга в режиме реального времени, объединяет уменьшение диаметра трубы с интеграцией приборов

преимущества

1. Три интегративных дизайна:Концентрический редуктор: Коаксиальное выравнивание, плавный поток жидкости при переходе и 30% меньшая потеря давления;Соединение с канавкой: Система GROOVE с быстроразъемными фитингами на основных линиях с обоих концов, высокая сейсмостойкость и класс номинального давления 300-500 psi; Трубы ответвления с внутренней резьбой (NPT/BSPT): все калибровочное оборудование путем затягивания внутренней резьбы для устранения места уплотнения.

2. Установка в течение минуты: Соединение с энергетической канавкой, экономия на сварке или выравнивании фланцев; Прямое прикручивание резьбовой ветки трубопровода к оборудованию (например, топливному баку); Тройная скорость при монтаже резьбовых ветвей трубопроводов

3. Чрезвычайная устойчивость к воздействию окружающей среды: Корпус из ковкого чугуна (ASTM A536) с красной краской/горячей оцинковкой, жидким эпоксидным покрытием, который устойчив к химической коррозии и обеспечивает отличную механическую устойчивость в диапазоне температур от -30°C до 150°.

4. Совместимость со всеми сценариями: Совместимость с трубами размером от 1-1¼”×1” до 8”×4” (DN40-DN200), что позволяет удовлетворить широкий спектр потребностей от бытового до промышленного применения

упаковка

- Тройной интерфейс Специальная защита:

- Порт канавки: Покрыт полиэтиленовой пленкой против царапин + защитное кольцо из пены EVA;

- Внутренняя резьба патрубка: Заливается антикоррозийной смазкой + вкручивается силиконовая уплотнительная втулка;

- Редукционный конус: Обернут амортизирующим слоем из пузырьковой прокладки, маркирован стрелкой направления потока “большой конец → малый конец”.

- Многослойная упаковка для защиты от терроризма:

- ≤4″: 10 штук в коробке, патрубки закреплены вверху на перегородках из сотового картона;

- >4″: Каждая деталь поддерживается специальными формами из пенопласта, а снаружи добавлена восьмиугольная картонная коробка для защиты от давления.

- Интеллектуальная система отслеживания:

- Коробки с маркировкой резьбовых патрубков ↑ и предупреждающими надписями о номинальном давлении;

- В комплект входит запечатанный пакет, содержащий двустороннюю карту проверки (включая направление редуктора + указания по резьбовому адаптеру).

Доступный размер

Размер | От конца до конца | ||

Дюйм | DN | мм | L (мм) |

1-1/2” × 1” | 40 × 25 | 48.3 × 33.7 | 64 |

2″ × 1/2″ | 50 × 15 | 60.3 × 21.3 | 64 |

2″ × 3/4″ | 50 × 20 | 60.3 × 26.9 | 64 |

2″ × 1″ | 50 × 25 | 60.3 × 33.7 | 64 |

2″ × 1-1/4″ | 50 × 32 | 60.3 × 42.4 | 64 |

2″ × 1-1/2″ | 50 × 40 | 60.3 × 48.3 | 64 |

2-1/2″ × 1″ | 65 × 25 | 73.0 × 33.7 | 64 |

2-1/2″ × 1-1/4″ | 65 × 32 | 73.0 × 42.4 | 64 |

2-1/2″ × 1-1/2″ | 65 × 40 | 73.0 × 48.3 | 64 |

2-1/2″ × 2″ | 65 × 50 | 73.0 × 60.3 | 64 |

2-1/2″ × 1/2″ | 65 × 15 | 76.1 × 21.3 | 64 |

2-1/2″ × 3/4″ | 65 × 20 | 76.1 × 26.9 | 64 |

2-1/2″ × 1″ | 65 × 25 | 76.1 × 33.7 | 64 |

2-1/2″ × 1-1/4″ | 65 × 32 | 76.1 × 42.4 | 64 |

2-1/2″ × 1-1/2″ | 65 × 40 | 76.1 × 48.3 | 64 |

2-1/2″ × 2″ | 65 × 50 | 76.1 × 60.3 | 64 |

3″ × 1″ | 80 × 25 | 88.9 × 33.7 | 64 |

3″ × 1-1/4″ | 80 × 32 | 88.9 × 42.4 | 64 |

3″ × 1-1/2″ | 80 × 40 | 88.9 × 48.3 | 64 |

3″ × 2″ | 80 × 50 | 88.9 × 60.3 | 64 |

3″ × 2-1/2″ | 80 × 65 | 88.9 × 73.0 | 64 |

3″ × 2-1/2″ | 80 × 65 | 88.9 × 76.1 | 64 |

4″ × 1″ | 100 × 25 | 114.3 × 33.7 | 76 |

4″ × 1-1/4″ | 100 × 32 | 114.3 × 42.4 | 76 |

4″ × 1-1/2″ | 100 × 40 | 114.3 × 48.3 | 76 |

4″ × 2″ | 100 × 50 | 114.3 × 60.3 | 76 |

4″ × 2-1/2″ | 100 × 65 | 114.3 × 73.0 | 76 |

4″ × 2-1/2″ | 100 × 65 | 114.3 × 76.1 | 76 |

4″ × 3″ | 100 × 80 | 114.3 × 88.9 | 76 |

5″ × 1″ | 125 × 25 | 139.7 × 33.7 | 89 |

5″ × 1-1/4″ | 125 × 32 | 139.7 × 42.4 | 89 |

5″ × 1-1/2″ | 125 × 40 | 139.7 × 48.3 | 89 |

5″ × 2″ | 125 × 50 | 139.7 × 60.3 | 89 |

5″ × 2-1/2″ | 125 × 65 | 139.7 × 76.1 | 89 |

5″ × 3″ | 125 × 80 | 139.7 × 88.9 | 89 |

5″ × 4″ | 125 × 100 | 139.7 × 114.3 | 89 |

6″ × 1″ | 150 × 25 | 165.1 × 33.7 | 102 |

6″ × 1-1/4″ | 150 × 32 | 165.1 × 42.4 | 102 |

6″ × 1-1/2″ | 150 × 40 | 165.1 × 48.3 | 102 |

6″ × 2″ | 150 × 50 | 165.1 × 60.3 | 102 |

6″ × 2-1/2″ | 150 × 65 | 165.1 × 76.1 | 102 |

6″ × 3″ | 150 × 80 | 165.1 × 88.9 | 102 |

6″ × 4″ | 150 × 100 | 165.1 × 114.3 | 102 |

6″ × 1″ | 150 × 25 | 168.3 × 33.7 | 102 |

6″ × 2″ | 150 × 50 | 168.3 × 60.3 | 102 |

6″ × 3″ | 150 × 80 | 168.3 × 88.9 | 102 |

6″ × 4″ | 150 × 100 | 168.3 × 114.3 | 102 |

8″ × 1-1/2″ | 200 × 40 | 219.1 × 48.3 | 127 |

6″ × 4″ | 150 × 100 | 168.3 × 114.3 | 102 |

8″ × 1-1/2″ | 200 × 40 | 219.1 × 48.3 | 127 |

8″ × 2″ | 200 × 50 | 219.1 × 60.3 | 127 |

8″ × 2-1/2″ | 200 × 65 | 219.1 × 76.1 | 127 |

8″ × 3″ | 200 × 80 | 219.1 × 88.9 | 127 |

8″ × 4″ | 200 × 100 | 219.1 × 114.3 | 127 |

- Обновление интеграции оборудования: Специально разработанные для систем, требующих одновременного изменения диаметра труб и подключения оборудования, ответвления с внутренней резьбой напрямую подключаются к таким приборам, как манометры и предохранительные клапаны, что подходит для таких ответственных узлов, как насосные станции и энергетические установки.

- Компактная оптимизация пространства: Концентрическая структура изменения диаметра экономит монтажное пространство, подходит для узких мест, таких как трубные колодцы и слои оборудования, предотвращая риски утечки, вызванные несколькими адаптерами.

- Прецизионный контроль жидкости: Это решение, разработанное для малорасходных ответвлений в системах ОВКВ и водоподготовки, требующих мониторинга в режиме реального времени, объединяет уменьшение диаметра трубы с интеграцией приборов

1. Три интегративных дизайна:Концентрический редуктор: Коаксиальное выравнивание, плавный поток жидкости при переходе и 30% меньшая потеря давления;Соединение с канавкой: Система GROOVE с быстроразъемными фитингами на основных линиях с обоих концов, высокая сейсмостойкость и класс номинального давления 300-500 psi; Трубы ответвления с внутренней резьбой (NPT/BSPT): все калибровочное оборудование путем затягивания внутренней резьбы для устранения места уплотнения.

2. Установка в течение минуты: Соединение с энергетической канавкой, экономия на сварке или выравнивании фланцев; Прямое прикручивание резьбовой ветки трубопровода к оборудованию (например, топливному баку); Тройная скорость при монтаже резьбовых ветвей трубопроводов

3. Чрезвычайная устойчивость к воздействию окружающей среды: Корпус из ковкого чугуна (ASTM A536) с красной краской/горячей оцинковкой, жидким эпоксидным покрытием, который устойчив к химической коррозии и обеспечивает отличную механическую устойчивость в диапазоне температур от -30°C до 150°.

4. Совместимость со всеми сценариями: Совместимость с трубами размером от 1-1¼”×1” до 8”×4” (DN40-DN200), что позволяет удовлетворить широкий спектр потребностей от бытового до промышленного применения

- Тройной интерфейс Специальная защита:

- Порт канавки: Покрыт полиэтиленовой пленкой против царапин + защитное кольцо из пены EVA;

- Внутренняя резьба патрубка: Заливается антикоррозийной смазкой + вкручивается силиконовая уплотнительная втулка;

- Редукционный конус: Обернут амортизирующим слоем из пузырьковой прокладки, маркирован стрелкой направления потока “большой конец → малый конец”.

- Многослойная упаковка для защиты от терроризма:

- ≤4″: 10 штук в коробке, патрубки закреплены вверху на перегородках из сотового картона;

- >4″: Каждая деталь поддерживается специальными формами из пенопласта, а снаружи добавлена восьмиугольная картонная коробка для защиты от давления.

- Интеллектуальная система отслеживания:

- Коробки с маркировкой резьбовых патрубков ↑ и предупреждающими надписями о номинальном давлении;

- В комплект входит запечатанный пакет, содержащий двустороннюю карту проверки (включая направление редуктора + указания по резьбовому адаптеру).

Получите коммерческое предложение на заказ стальных труб сегодня!

Предоставьте нам детали вашего проекта (например, применение, спецификации, количество). Наша опытная команда предложит индивидуальное решение и конкурентоспособное предложение в течение 24 рабочих часов.