HOT PRODUCTS TAGS

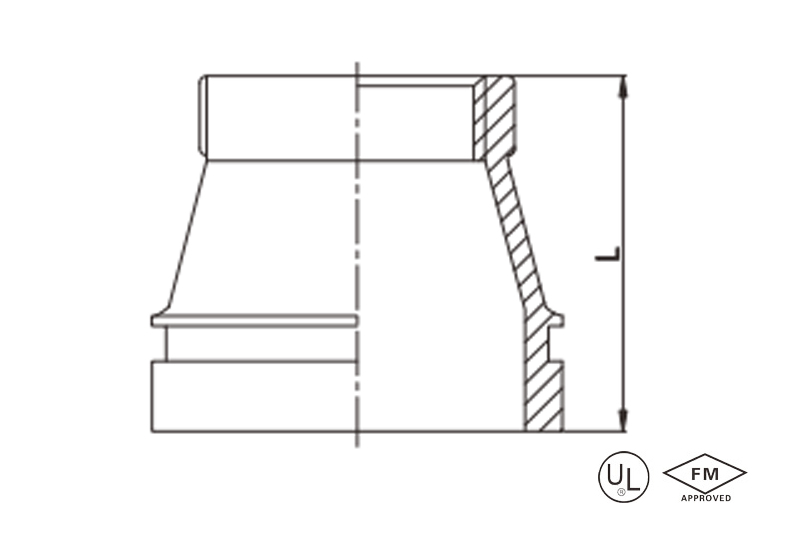

Grooved concentric reducer with female threaded outlet

·Standard: ANSI / UL 213C UL / FM

·Material: Ductile iron ASTM A536, 65-45-12

·Thread run: Female thread, NPT / BSPT

·Rated pressure: 300 – 500 psi

·Surface: Red painting / hot dip galvanized

·Size range: 1-1/2”×1” – 8″×4″

description

Grooved concentric reducer with female threaded outlet is a concentric reducer with different pipe diameters at both ends and overlapping centerlines. The outlet end is designed with an internal thread and is used to connect pipes of different pipe diameters and adapt to internal thread components

Specification

Available size

Size | End to end | ||

Inch | DN | mm | L(mm) |

1-1/2” × 1” | 40 × 25 | 48.3 × 33.7 | 64 |

2″ × 1/2″ | 50 × 15 | 60.3 × 21.3 | 64 |

2″ × 3/4″ | 50 × 20 | 60.3 × 26.9 | 64 |

2″ × 1″ | 50 × 25 | 60.3 × 33.7 | 64 |

2″ × 1-1/4″ | 50 × 32 | 60.3 × 42.4 | 64 |

2″ × 1-1/2″ | 50 × 40 | 60.3 × 48.3 | 64 |

2-1/2″ × 1″ | 65 × 25 | 73.0 × 33.7 | 64 |

2-1/2″ × 1-1/4″ | 65 × 32 | 73.0 × 42.4 | 64 |

2-1/2″ × 1-1/2″ | 65 × 40 | 73.0 × 48.3 | 64 |

2-1/2″ × 2″ | 65 × 50 | 73.0 × 60.3 | 64 |

2-1/2″ × 1/2″ | 65 × 15 | 76.1 × 21.3 | 64 |

2-1/2″ × 3/4″ | 65 × 20 | 76.1 × 26.9 | 64 |

2-1/2″ × 1″ | 65 × 25 | 76.1 × 33.7 | 64 |

2-1/2″ × 1-1/4″ | 65 × 32 | 76.1 × 42.4 | 64 |

2-1/2″ × 1-1/2″ | 65 × 40 | 76.1 × 48.3 | 64 |

2-1/2″ × 2″ | 65 × 50 | 76.1 × 60.3 | 64 |

3″ × 1″ | 80 × 25 | 88.9 × 33.7 | 64 |

3″ × 1-1/4″ | 80 × 32 | 88.9 × 42.4 | 64 |

3″ × 1-1/2″ | 80 × 40 | 88.9 × 48.3 | 64 |

3″ × 2″ | 80 × 50 | 88.9 × 60.3 | 64 |

3″ × 2-1/2″ | 80 × 65 | 88.9 × 73.0 | 64 |

3″ × 2-1/2″ | 80 × 65 | 88.9 × 76.1 | 64 |

4″ × 1″ | 100 × 25 | 114.3 × 33.7 | 76 |

4″ × 1-1/4″ | 100 × 32 | 114.3 × 42.4 | 76 |

4″ × 1-1/2″ | 100 × 40 | 114.3 × 48.3 | 76 |

4″ × 2″ | 100 × 50 | 114.3 × 60.3 | 76 |

4″ × 2-1/2″ | 100 × 65 | 114.3 × 73.0 | 76 |

4″ × 2-1/2″ | 100 × 65 | 114.3 × 76.1 | 76 |

4″ × 3″ | 100 × 80 | 114.3 × 88.9 | 76 |

5″ × 1″ | 125 × 25 | 139.7 × 33.7 | 89 |

5″ × 1-1/4″ | 125 × 32 | 139.7 × 42.4 | 89 |

5″ × 1-1/2″ | 125 × 40 | 139.7 × 48.3 | 89 |

5″ × 2″ | 125 × 50 | 139.7 × 60.3 | 89 |

5″ × 2-1/2″ | 125 × 65 | 139.7 × 76.1 | 89 |

5″ × 3″ | 125 × 80 | 139.7 × 88.9 | 89 |

5″ × 4″ | 125 × 100 | 139.7 × 114.3 | 89 |

6″ × 1″ | 150 × 25 | 165.1 × 33.7 | 102 |

6″ × 1-1/4″ | 150 × 32 | 165.1 × 42.4 | 102 |

6″ × 1-1/2″ | 150 × 40 | 165.1 × 48.3 | 102 |

6″ × 2″ | 150 × 50 | 165.1 × 60.3 | 102 |

6″ × 2-1/2″ | 150 × 65 | 165.1 × 76.1 | 102 |

6″ × 3″ | 150 × 80 | 165.1 × 88.9 | 102 |

6″ × 4″ | 150 × 100 | 165.1 × 114.3 | 102 |

6″ × 1″ | 150 × 25 | 168.3 × 33.7 | 102 |

6″ × 2″ | 150 × 50 | 168.3 × 60.3 | 102 |

6″ × 3″ | 150 × 80 | 168.3 × 88.9 | 102 |

6″ × 4″ | 150 × 100 | 168.3 × 114.3 | 102 |

8″ × 1-1/2″ | 200 × 40 | 219.1 × 48.3 | 127 |

6″ × 4″ | 150 × 100 | 168.3 × 114.3 | 102 |

8″ × 1-1/2″ | 200 × 40 | 219.1 × 48.3 | 127 |

8″ × 2″ | 200 × 50 | 219.1 × 60.3 | 127 |

8″ × 2-1/2″ | 200 × 65 | 219.1 × 76.1 | 127 |

8″ × 3″ | 200 × 80 | 219.1 × 88.9 | 127 |

8″ × 4″ | 200 × 100 | 219.1 × 114.3 | 127 |

application

- Equipment integration renovation: Specifically designed for systems that require simultaneous pipe diameter changes and equipment connection, internal threaded branch pipes are directly connected to instruments such as pressure gauges and relief valves, suitable for critical nodes such as pump rooms and energy stations.

- Compact space optimization: The concentric diameter change structure saves installation space, suitable for narrow areas such as pipe wells and equipment layers, avoiding leakage risks caused by multiple adapters.

- Precision Fluid Control: Designed for small-flow branches in HVAC and water treatment systems that require real-time monitoring, this solution integrates pipe diameter reduction with instrumentation integration

advantages

1. Three integrative design:Concentric Reducer: Coaxial alignment, smooth fluid flow during transition, and 30% lower pressure loss;Groove Connection: GROOVE system with quick-fit fittings on main lines at both ends, high seismic resistance and 300-500 psi rated pressure class; Internal Threaded Branch Pipes (NPT/BSPT): All calibration equipment by tightening the internal thread to eliminate sealing point.

2. Installation Along Minute: Energy Groove Connection, Save Welding or Flange Alignment;Thread Branch pipeline Direct Screw to the equipment(e.g. fuel tank);Triple Speed for Installation of Thread branch pipelines

3. Extraordinary environmental resistance: Ductile iron body(ASTM A536) with red paint/hot-dip galvanized, liquid epoxy coated which is anti-resistant to chemical corrosion and provide excellent mechanical stabilities in the temperature range of -30°C to 150°

4. All-scenario compatibility: Compatible with pipe sizes ranging from 1-1¼”×1” to 8”×4” (DN40-DN200), so able to meet wide range of needs from residential to industrial applications

packing

- Triple Interface Special Protection:

- Groove Port: Covered with PE anti-scratch film + EVA foam protective ring;

- Internal Thread Branch Pipe: Injected with anti-rust grease + screwed-in silicone seal sleeve;

- Reducing Cone: Wrapped with bubble pad cushioning layer, marked with “large end → small end” flow direction arrow.

- Anti-error Layered Packaging:

- ≤4″: 10 pieces per box, branch pipes fixed upward on honeycomb cardboard partitions;

- >4″: Each piece supported by custom foam molds, with an octagonal anti-pressure cardboard box added externally.

- Smart Traceability System:

- Boxes printed with threaded branch pipe markings ↑ and pressure rating warning labels;

- Includes a sealed bag containing a two-way verification card (including reducer direction + threaded adapter guidelines).

Available size

Size | End to end | ||

Inch | DN | mm | L(mm) |

1-1/2” × 1” | 40 × 25 | 48.3 × 33.7 | 64 |

2″ × 1/2″ | 50 × 15 | 60.3 × 21.3 | 64 |

2″ × 3/4″ | 50 × 20 | 60.3 × 26.9 | 64 |

2″ × 1″ | 50 × 25 | 60.3 × 33.7 | 64 |

2″ × 1-1/4″ | 50 × 32 | 60.3 × 42.4 | 64 |

2″ × 1-1/2″ | 50 × 40 | 60.3 × 48.3 | 64 |

2-1/2″ × 1″ | 65 × 25 | 73.0 × 33.7 | 64 |

2-1/2″ × 1-1/4″ | 65 × 32 | 73.0 × 42.4 | 64 |

2-1/2″ × 1-1/2″ | 65 × 40 | 73.0 × 48.3 | 64 |

2-1/2″ × 2″ | 65 × 50 | 73.0 × 60.3 | 64 |

2-1/2″ × 1/2″ | 65 × 15 | 76.1 × 21.3 | 64 |

2-1/2″ × 3/4″ | 65 × 20 | 76.1 × 26.9 | 64 |

2-1/2″ × 1″ | 65 × 25 | 76.1 × 33.7 | 64 |

2-1/2″ × 1-1/4″ | 65 × 32 | 76.1 × 42.4 | 64 |

2-1/2″ × 1-1/2″ | 65 × 40 | 76.1 × 48.3 | 64 |

2-1/2″ × 2″ | 65 × 50 | 76.1 × 60.3 | 64 |

3″ × 1″ | 80 × 25 | 88.9 × 33.7 | 64 |

3″ × 1-1/4″ | 80 × 32 | 88.9 × 42.4 | 64 |

3″ × 1-1/2″ | 80 × 40 | 88.9 × 48.3 | 64 |

3″ × 2″ | 80 × 50 | 88.9 × 60.3 | 64 |

3″ × 2-1/2″ | 80 × 65 | 88.9 × 73.0 | 64 |

3″ × 2-1/2″ | 80 × 65 | 88.9 × 76.1 | 64 |

4″ × 1″ | 100 × 25 | 114.3 × 33.7 | 76 |

4″ × 1-1/4″ | 100 × 32 | 114.3 × 42.4 | 76 |

4″ × 1-1/2″ | 100 × 40 | 114.3 × 48.3 | 76 |

4″ × 2″ | 100 × 50 | 114.3 × 60.3 | 76 |

4″ × 2-1/2″ | 100 × 65 | 114.3 × 73.0 | 76 |

4″ × 2-1/2″ | 100 × 65 | 114.3 × 76.1 | 76 |

4″ × 3″ | 100 × 80 | 114.3 × 88.9 | 76 |

5″ × 1″ | 125 × 25 | 139.7 × 33.7 | 89 |

5″ × 1-1/4″ | 125 × 32 | 139.7 × 42.4 | 89 |

5″ × 1-1/2″ | 125 × 40 | 139.7 × 48.3 | 89 |

5″ × 2″ | 125 × 50 | 139.7 × 60.3 | 89 |

5″ × 2-1/2″ | 125 × 65 | 139.7 × 76.1 | 89 |

5″ × 3″ | 125 × 80 | 139.7 × 88.9 | 89 |

5″ × 4″ | 125 × 100 | 139.7 × 114.3 | 89 |

6″ × 1″ | 150 × 25 | 165.1 × 33.7 | 102 |

6″ × 1-1/4″ | 150 × 32 | 165.1 × 42.4 | 102 |

6″ × 1-1/2″ | 150 × 40 | 165.1 × 48.3 | 102 |

6″ × 2″ | 150 × 50 | 165.1 × 60.3 | 102 |

6″ × 2-1/2″ | 150 × 65 | 165.1 × 76.1 | 102 |

6″ × 3″ | 150 × 80 | 165.1 × 88.9 | 102 |

6″ × 4″ | 150 × 100 | 165.1 × 114.3 | 102 |

6″ × 1″ | 150 × 25 | 168.3 × 33.7 | 102 |

6″ × 2″ | 150 × 50 | 168.3 × 60.3 | 102 |

6″ × 3″ | 150 × 80 | 168.3 × 88.9 | 102 |

6″ × 4″ | 150 × 100 | 168.3 × 114.3 | 102 |

8″ × 1-1/2″ | 200 × 40 | 219.1 × 48.3 | 127 |

6″ × 4″ | 150 × 100 | 168.3 × 114.3 | 102 |

8″ × 1-1/2″ | 200 × 40 | 219.1 × 48.3 | 127 |

8″ × 2″ | 200 × 50 | 219.1 × 60.3 | 127 |

8″ × 2-1/2″ | 200 × 65 | 219.1 × 76.1 | 127 |

8″ × 3″ | 200 × 80 | 219.1 × 88.9 | 127 |

8″ × 4″ | 200 × 100 | 219.1 × 114.3 | 127 |

- Equipment integration renovation: Specifically designed for systems that require simultaneous pipe diameter changes and equipment connection, internal threaded branch pipes are directly connected to instruments such as pressure gauges and relief valves, suitable for critical nodes such as pump rooms and energy stations.

- Compact space optimization: The concentric diameter change structure saves installation space, suitable for narrow areas such as pipe wells and equipment layers, avoiding leakage risks caused by multiple adapters.

- Precision Fluid Control: Designed for small-flow branches in HVAC and water treatment systems that require real-time monitoring, this solution integrates pipe diameter reduction with instrumentation integration

1. Three integrative design:Concentric Reducer: Coaxial alignment, smooth fluid flow during transition, and 30% lower pressure loss;Groove Connection: GROOVE system with quick-fit fittings on main lines at both ends, high seismic resistance and 300-500 psi rated pressure class; Internal Threaded Branch Pipes (NPT/BSPT): All calibration equipment by tightening the internal thread to eliminate sealing point.

2. Installation Along Minute: Energy Groove Connection, Save Welding or Flange Alignment;Thread Branch pipeline Direct Screw to the equipment(e.g. fuel tank);Triple Speed for Installation of Thread branch pipelines

3. Extraordinary environmental resistance: Ductile iron body(ASTM A536) with red paint/hot-dip galvanized, liquid epoxy coated which is anti-resistant to chemical corrosion and provide excellent mechanical stabilities in the temperature range of -30°C to 150°

4. All-scenario compatibility: Compatible with pipe sizes ranging from 1-1¼”×1” to 8”×4” (DN40-DN200), so able to meet wide range of needs from residential to industrial applications

- Triple Interface Special Protection:

- Groove Port: Covered with PE anti-scratch film + EVA foam protective ring;

- Internal Thread Branch Pipe: Injected with anti-rust grease + screwed-in silicone seal sleeve;

- Reducing Cone: Wrapped with bubble pad cushioning layer, marked with “large end → small end” flow direction arrow.

- Anti-error Layered Packaging:

- ≤4″: 10 pieces per box, branch pipes fixed upward on honeycomb cardboard partitions;

- >4″: Each piece supported by custom foam molds, with an octagonal anti-pressure cardboard box added externally.

- Smart Traceability System:

- Boxes printed with threaded branch pipe markings ↑ and pressure rating warning labels;

- Includes a sealed bag containing a two-way verification card (including reducer direction + threaded adapter guidelines).

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.