3PE vs. FBE: How to Choose the Best Anti-Corrosion Coating for Your Steel Pipes?

Introduction: the best armor is “the most suitable” armor

For steel pipes in oil/gas, municipal water, or industrial fluid transport, corrosion is an invisible threat causing major losses and risks. Choosing the right anti-corrosion coating for steel pipes is a strategic investment-high quality coatings can extend the service life of pipelines from several years to several decades, reduce maintenance costs and avoid unexpected downtime.

In today’s market, 3PE corrosion protection and FBE corrosion protection are the main protection methods for medium/large diameter steel pipe. Both of them have unique advantages, but piping engineers, anti-corrosion experts, project managers and purchasing personnel often want to know “which is better” This article objectively compares 3PE and FBE, clarifying differences in structure, performance, application, and cost to guide your choice.

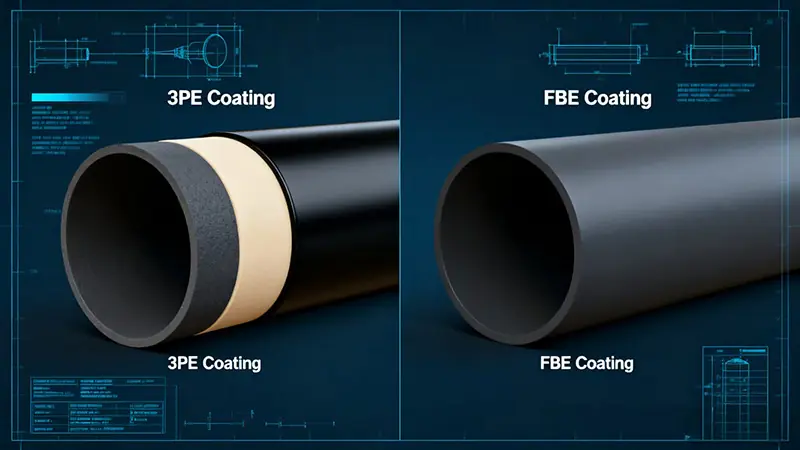

Structural Differences: single layer “shield” vs. three layers “heavy armor”

The core difference between 3PE anti-corrosion and FBE anti-corrosion is their structure, which determines their performance.

FBE Anti–corrosion: Single layer “shielding” with strong adhesion

FBE anti-corrosion (Fusion Bonded Epoxy) is a single-layer system. After steel pipe surface treatment (typically shot-blasted for roughness), special epoxy powder is sprayed uniformly.

3PE anti–corrosion: three layers of “heavy armor” with composite functions

Different from FBE anti–corrosion, 3PE anti–corrosion (three-layer polyethylene) is a multi-functional composite system with three synergistic layers.

· Inner Epoxy Layer: Directly contacts the pipe, made of epoxy powder (like FBE anti-corrosion). Applied to a thickness of 100-150 µm, this layer bonds the entire coating system to the steel and provides primary corrosion resistance.

· Intermediate adhesive layer: Modified polyethylene (150-200 microns) connects inner epoxy resin and outer polyethylene to solve compatibility and prevent peeling.

· Outer Polyethylene Layer: High-density polyethylene (2-3 mm, thicker if needed) resists impact, wear, and environmental cracking, shielding against mechanical damage and external corrosion (soil, water, microbes).

Performance comparison: Core Differences at a glance

The main performance indicators are summarized as follows.

| Performance Indicator | 3PE Anti-Corrosion | FBE Anti – corrosion |

| Structure | Three layers of structure (epoxy resin+adhesive+polyethylene) | single layer (welded epoxy resin). |

| Resistance to Mechanical Damage | Excellent: Thick polyethylene resists impact, wear, extrusion—ideal for harsh sites (trench less work, rocky soil). | Fair: While the coating is very hard, it can be brittle. It is susceptible to cracking or chipping under strong impact-not suitable for high damage areas. |

| Adhesion to Steel Pipes | High: Integrated three-layer structure, average adhesion ≥ 100 n/cm. | Excellent: The coating is fused directly to the steel substrate, creating a powerful bond that is highly resistant to peeling |

| Chemical Corrosion Resistance | Good: Resists soil, groundwater, general organics; Weak acid and strong acid/alkali (pH value < 4 or > 12). | Excellent: Resistant to strong acids, strong alkalis, salt and most organic substances, and ideal for harsh chemical environment. |

| Suitable Temperature range | -40℃ to 80℃: polyethylene will soften at high temperature-not suitable for steam pipes. | -40℃ to 120℃: Modified FBE handles up to 150℃—good for medium/high-temp pipes. |

| Weather Resistance | Good: UV-resistant polyethylene ages with long sunlight—needs protection for above-ground use. | Overview: epoxy chalk under ultraviolet light/aging-not suitable for unprotected above-ground use. |

| Construction Complexity | High: Precise control of each layer’s temp/speed/thickness; It needs professional equipment and personnel. | Low: simple single layer spray curing process; High efficiency, low demand for equipment/operators. |

Application Scenarios: who is the “king” in specific fields?

Performance differences defines their “domain”.

FBE Anti–corrosion: An Expert in High Temperature and Chemical Environment

· High-Temperature Pipes: With 120℃ resistance, FBE anti-corrosion suits thermal power steam pipes, refinery hot oil lines, and industrial high-temp water pipes.

· Inner Walls of pipeline: For corrosive media (acid sewage, chemicals and high-salt oilfield fluids), its single-layer structure avoids interlayer infiltration, and has strong chemical resistance and resistance to internal erosion.

· Chemical pipeline: shielded pipeline for transporting sulfuric acid, hydrochloric acid or methanol in chemical plants.

· Small/Complex Pipes: Simple processing suits DN 50-DN 200 pipes or elbows.

3PE Anti-Corrosion: the “Champion” in Buried and Harsh Construction Sites

· Buried Long-Distance Pipes: Widely used for oil/gas, municipal gas, and water pipelines. Thick polyethylene can resist buried damage (mechanical impact, soil friction) and corrosion (microorganisms, groundwater).

· Rocky/Complex Soil: Withstands impact/extrusion from soil settlement or rocks. FBE anti-corrosion is too brittle for this.

· Large-Diameter Pipes: Ensures uniform coating for DN 800+cross-river/sea or water pipes, adapting to thermal expansion to avoid cracking.

· Long-term maintenance-free Use: Although the initial cost is high, low maintenance and long life reduce failure risks of strategic oil/gas or cross-border water pipelines.

Cost Consideration: Initial Investment vs. Long-Term Value

Cost is very important, but we should pay attention to the life cycle costs (initial cost, maintenance cost, replacement cost, failure losses), not just upfront cost.

Initial Investment: FBE Anti-Corrosion Has an Advantage

FBE is 20% -30% cheaper in the early stage.

· Simpler Process: One spray-cure step lowers equipment/energy costs vs. 3PE’s three-layer line (needs adhesive/polyethylene gear).

· Less material: 300-500m FBE uses less material than 2.5mm +3 polyethylene.

· Lower labor/time: higher efficiency, handling more pipelines every day; 3PE requires skilled employees and longer production time.

For small systems (temporary industrial pipelines) with tight budget and time, FBE corrosion protection is cheaper in the short term.

Long-Term Value: 3PE Anti-Corrosion is More Cost – Effective

While the initial investment for 3PE coating is higher, it often delivers superior long-term value and a lower total cost of ownership (TCO).

· Longer service Life: 30-50 years, while FBE (harsh environment) is 15-25 years, reducing the expensive replacements cost.

· Low maintenance cost: resistance to damage; Local maintenance is enough. FBE is easy to crack/fall off, and needs to be repaired on a large scale.

· Less failure Loss: avoid shutdowns, accidents (oil leakage) or pollution for key pipelines-save more than the original cost gaps.

For long-term, large-scale and high-reliability projects (municipal buried and long-distance oil and gas pipelines), 3PE anti–corrosion has reduced the life cycle costs.

Conclusions and call for action

There’s no “better” choice between 3PE anti-corrosion and FBE anti-corrosion, only “suitable” Choose according to project requirements: environment (temperature, corrosion, pressure), scale, life expectancy and budget.

Choose FBE corrosion protection for high temperature, chemistry, small/complex pipelines or the situation of tight budgets in the early stage.

For buried pipelines with long distance, large diameter, harsh site or maintenance-free, choose 3PE for anti-corrosion.

As anti-corrosion experts, we have rich experience in 3PE anti-corrosion and FBE anti-corrosion. Whether you are a piping engineer who needs support, an anti-corrosion expert who explores technology, a project manager who pays attention to cost or a purchasing expert, please contact our team to obtain a free customized selection report to protect the long-term safety and efficiency of your pipeline.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.