How Many Steel Pipes Fit in a Container? (20GP vs 40HC)

Introduction

“How many pipes can we fit in one container?”

As a project manager or procurement specialist sourcing steel pipe from China, this is likely one of the first questions you ask after getting a product price. And for good reason—ocean freight can account for a significant percentage of your total landed cost, especially for large-diameter LSAW and SSAW pipes which take up immense volume.

Calculating loading capacity isn’t only about the weight; it’s a game of “Tetris” with pipe diameter, container size and the limits of length. Selecting a wrong container type (like booking for a 40GP when a 40HC could carry 20% more pipe) can cost you thousands of dollars in “dead freight.”

Consider this guide as your logistics calculator. Based on actual loading data (see our reference chart below), we’ll reveal exactly how many pipes of different diameters you can fit in a standard container, highlight the all-important differences between 20GP, 40GP and 40HC, and provide Allland’s best tips for helping you get the maximum from your shipment.

The Containers: 20GP vs. 40GP vs. 40HC

Before looking at the pipe count, you must understand the constraints of the box.

- 20ft General Purpose (20GP):

- Max Pipe Length: 5.8 meters (19 ft).

- Best For: Heavy, short pipes or small quantity orders. If your project accepts “Random Lengths” (e.g., 6m), these pipes often must be cut to 5.8m to fit, or shipped in a 40ft container.

- 40ft General Purpose (40GP):

- Max Pipe Length: 11.8 meters (39 ft).

- Best For: The industry standard for 12-meter pipes (cut slightly short).

- 40ft High Cube (40HC / 40HQ):

- Max Pipe Length: 11.8 meters.

- The Advantage: It is 30cm (1 foot) taller than a GP container.

- Best For: This extra height is critical for small-to-medium diameter pipes (e.g., 168mm – 406mm). As you will see in the chart below, a 40HC can often hold significantly more layers of pipe than a 40GP, reducing your average freight cost per ton.

The Loading Chart (Data Analysis)

Based on standard logistics data, here is a breakdown of how many pieces (pcs) of steel pipe fit into a single container based on the Outer Diameter (OD).

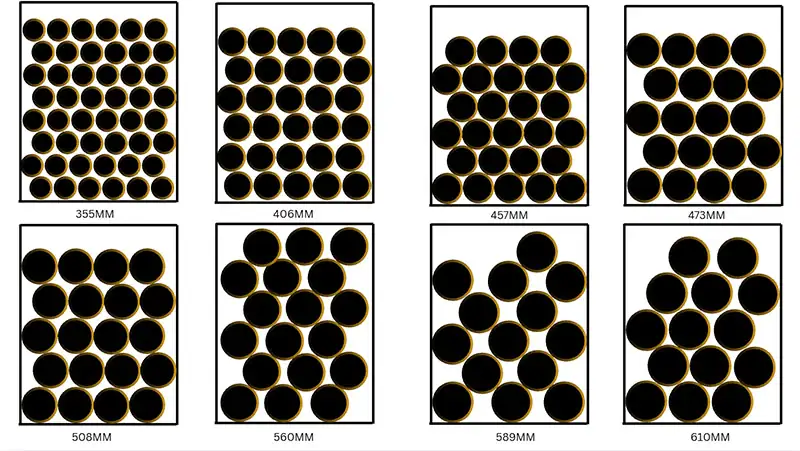

Figure 1: Cross-section view showing loading capacity for medium-to-large diameter pipes (355mm – 610mm) in a 40ft High Cube container. The square container shape limits stacking efficiency as diameter increases.

| Specification (OD) | 20ft Container (20GP) | 40ft General Container (40GP) | 40ft High Cube (40HC) |

| mm (inch) | Max Pieces (pcs) | Max Pieces (pcs) | Max Pieces (pcs) |

| 168 mm (6″) | 169 | 169 | 225 |

| 219 mm (8″) | 105 | 105 | 114 |

| 273 mm (10″) | 72 | 72 | 80 |

| 324 mm (12″) | 52 | 52 | 52 |

| 355.6 mm (14″) | 42 | 42 | 48 |

| 406.4 mm (16″) | 30 | 30 | 30 |

| 457 mm (18″) | 23 | 23 | 27 |

| 473 mm | 20 | 20 | 20 |

| 508 mm (20″) | 18 | 18 | 20 |

| 560 mm (22″) | 14 | 14 | 18 |

| 589 mm | 14 | 14 | 14 |

| 610 mm (24″) | 12 | 12 | 14 |

| 630 mm | 12 | 12 | 13 |

| 650 mm | 10 | 10 | 12 |

| 660.4 mm (26″) | 10 | 10 | 12 |

| 711.2 mm (28″) | 9 | 9 | 10 |

| 762 mm (30″) | 8 | 8 | 9 |

| 813 mm (32″) | 5 | 5 | 6 |

| 914 mm (36″) | 5 | 5 | 6 |

| 928 mm | 4 | 4 | 5 |

| 938 mm | 4 | 4 | 5 |

| 1016 mm (40″) | 4 | 4 | 4 |

| 1067 mm (42″) | 4 | 4 | 4 |

| 1118 mm (44″) | 4 | 4 | 4 |

| 1210 mm (48″) | 2 | 2 | 3 |

| 1422 mm (56″) | 1 | 1 | 1 |

(Note: This data assumes the pipes are loose loaded to maximize space. Values are approximate and depend on wall thickness/flange/coupling interference.)

1. Small to Medium Diameters (The 40HC Advantage)

For pipes under 400mm, the 40HC container is the clear winner for cost efficiency.

| Pipe OD (mm) | Pipe OD (inch) | 20GP / 40GP Capacity (pcs) | 40HC Capacity (pcs) | The Allland Insight |

| 168 mm | 6″ | 169 pcs | 225 pcs | +33% Gain!The extra height of the HC allows for extra rows. |

| 219 mm | 8″ | 105 pcs | 114 pcs | Using a 40HC allows you to ship ~9% more pipe for roughly the same freight rate. |

| 273 mm | 10″ | 72 pcs | 80 pcs | Optimized stacking makes the difference. |

| 324 mm | 12″ | 52 pcs | 52 pcs | At this size, the geometry limits stacking, so GP and HC hold the same amount. |

2. Large Diameter LSAW/SSAW (Space Limited)

As the diameter increases, the “packing density” decreases. The container creates a rigid square limit.

| Pipe OD (mm) | Pipe OD (inch) | 20GP / 40GP Capacity (pcs) | 40HC Capacity (pcs) |

| 406.4 mm | 16″ | 30 pcs | 30 pcs |

| 508 mm | 20″ | 18 pcs | 20 pcs |

| 610 mm | 24″ | 12 pcs | 14 pcs |

| 914 mm | 36″ | 5 pcs | 6 pcs |

| 1210 mm | 48″ | 2 pcs | 3 pcs |

| 1422 mm | 56″ | 1 pcs | 1 pcs |

The 1422mm Limit: Note that for a 56-inch pipe (1422mm), only one single pipe fits in a container because the container door width is approximately 2340mm. You cannot fit two side-by-side. This results in very high freight costs per ton.

How to Lower Freight Costs (Allland’s Strategies)

When purchasing large diameters pipes (e.g. 914mm or 1016mm), shipping “air” inside the pipes is costly. Here is how Allland helps you optimize:

1. Pipe Nesting (The ”Pipe-in-Pipe” Method) This is by far the best way to save.If you want the 36″ (914mm) and the 16″ (406mm) pipes, we can nest the smaller pipes inside the bigger ones prior to packing.

2. Benefit: You effectively ship the smaller pipes for free.

3. Requirement: Must be planned during the ordering phase.

4. Length Optimization If your project permits, ordering pipes in lengths of 5.8m or 11.8m allows you to take advantage of the full container capacity.Ordering “12m exact” pipes many times requires Open Top containers or Break Bulk shipping, which is much more expensive than normal containers.

5. Bulk Break vs. Containers For orders of massive diameters (greater than 60″) or massive quantities (1,000+ tons), Bulk Break (bulk ship) transportation is usually more cost effective than containers.Allland’s logistics team compare all daily ocean freight rate to identify the cheapest option for your particular destination port.

Conclusion

Successful steel pipe buying is not so much the price per ton of steel; it is the landed cost at your site. The selection of the container (20GP, 40HC, etc.) and the loading quantity optimization (please use our above chart) may help to save about 10-30% logistics cost.At Allland we don’t only produce pipe, we logistics the logistics. No matter if you are purchasing standard ERW pipe or large-diameter LSAW pipe, our team will work out the best loading plan for you under your contract in advance, so you always won’t pay for “shipping air”.

FAQ

Q1: Why are the number of pieces for 20GP and 40GP same in the chart?

A1: The chart shows how many pipes you get in a cross-section. For instance, for the 610mm pipe, the face of the container can accommodate 12 pipes. A 20GP 12 pipes (5.8m length), a 40GP 12 pipes (11.8m length). It’s the same amount, but the combined length/tonnage within a 40GP is twice that.

Q2: What is the container max. weight?

A2: “But you’re not allowed to go over the weight limit, even if you have room for more pipes.” The maximum weight should be 21-25 tons for 20ft container and 26-28 tons for 40 ft container (vary from shipping line to shipping line). With thick wall pipes, you reach the weight limit long before you fill the volume.

Q3: Are pipe lengths exceeding 12 meters shippable by Allland?

A3: Yes. For pipes longer than 11.8m (e.g. 12m to 18m pile pipes) we ship in Open Top Containers or Bulk Break. We will offer a side by side quote option for you most affordable one.

Share:

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.

Related Articles

ASTM A53 vs. API 5L: A Guide to Selection and Application

Introduction:Technology differences determine success or failure, and selection needs to be “precise”

Steel Density Analysis: Core Differences between Mild and Medium Carbon Steels and Industrial Applications

3LPE coated steel pipe: a solid barrier in the field of industrial corrosion protection

3LPP coated pipe: anti-corrosion guard in high temperature and high pressure environment

FBE steel pipe: the technological armor of the steel defense line

HOT TAGS

latest posts

- FBE steel pipe: the technological armor of the steel defense line

- Precision Engineering Redefined Dubai’s Stadium Dome Construction

- An Engineer’s Guide: A Deep Dive into UOE vs. JCOE LSAW Steel Pipe Manufacturing

- Floating Pipelines: Key Views on Offshore Dynamic Risers & Marine Transportation Pipelines

- The Dance of Spiral Forming: How SSAW Steel Pipes Are Made