HOT PRODUCTS TAGS

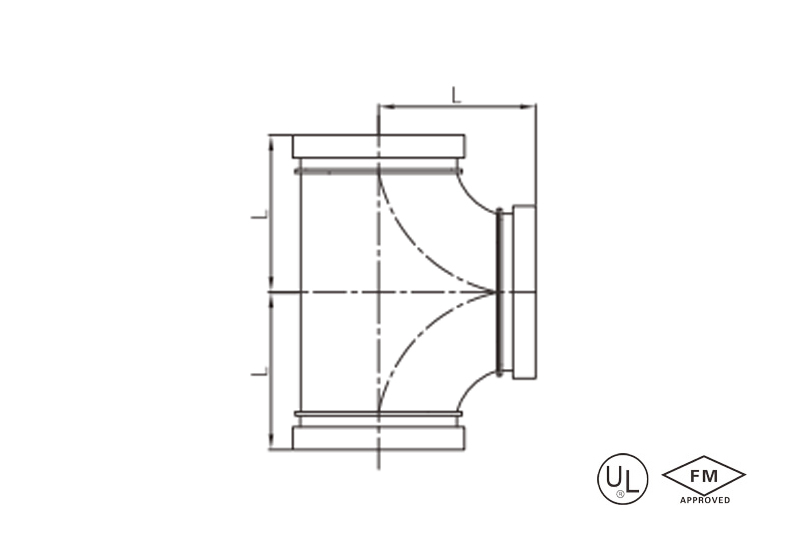

Grooved straight tee (Equal tee)

·Standard: ANSI / UL 213C UL / FM

·Material: Ductile iron ASTM A536, 65-45-12

·Type: Short / Standard

·Rated pressure: 300 – 500 psi

·Surface: Red painting / hot dip galvanized

·Size range: 1″ – 24″

description

Grooved straight tee (Equal tee) is an equal-diameter three-way pipe fitting with a grooved connection structure. The pipe diameters of the three interfaces are the same, and it is used in pipeline systems to achieve vertical branch connections of pipelines

Specification

Available size

Size | Center to end,L(mm) | |||

Inch | DN | mm | Short | Standard |

1″ | 25 | 33.7 | 57 | 57 |

1-1/4″ | 32 | 42.4 | 60 | 70 |

1-1/2″ | 40 | 48.3 | 60 | 70 |

2″ | 50 | 60.3 | 70 | 83 |

2-1/2″ | 65 | 73.0 | 76 | 95 |

2-1/2″ | 65 | 76.1 | 76 | 95 |

3″ | 80 | 88.9 | 86 | 108 |

4″ | 100 | 114.3 | 101 | 127 |

5″ | 125 | 139.7 | 124 | 140 |

5″ | 125 | 141.3 | 124 | 140 |

6″ | 150 | 165.1 | 140 | 165 |

6″ | 150 | 168.3 | 140 | 165 |

8″ | 200 | 219.1 | 175 | 197 |

10″ | 250 | 273.0 | 215 | 229 |

12″ | 300 | 323.9 | 245 | 254 |

14″ | 350 | 355.6 | / | 280 |

16″ | 400 | 406.4 | / | 305 |

18″ | 450 | 457.2 | / | 342 |

20″ | 500 | 508 | / | 381 |

24″ | 600 | 609.6 | / | 432 |

application

- Main pipeline diversion system: fire sprinkler piping network, HVAC main trunk pipes, achieving equal-diameter vertical branches to ensure balanced diversion flow.

- Equipment parallel connection: multiple devices in the pump room are connected in parallel for water supply/return, with three-way connectors reducing welding joints and lowering the risk of leakage.

- Space-optimized layout: building mechanical and electrical pipe shafts, ship pipe compartments, compact design (especially short types) saving 30% of installation space.

- Industrial Circulation System: Cooling tower circulation water and chemical medium transportation, with equal-diameter structures to prevent cavitation caused by sudden changes in local flow velocity.

- System Expansion and Renovation: Municipal water supply/industrial pipeline network upgrades, allowing new branches to be added without replacing the main pipeline (e.g., community water supply expansion).

advantages

- Dual types cover all scenarios:

- Short: Suitable for space-constrained areas (such as equipment compartments);

- Standard: Preferred for conventional branches, with less fluid disturbance;

- Long Type (Long) (14“-24”): Designed for extra-large pipe diameters, reducing high-pressure water hammer impact.

- Zero flow loss design: Equal-diameter three-way interface, branch pipe flow attenuation <5%, outperforming unequal-diameter tees.

- Triple sealing assurance:

- Ductile iron body (ASTM A536) resists deformation;

- Grooved ends with dual sealing rings for seismic resistance and anti-loosening;

- Hot-dip galvanized coating (≥80μm) resists chemical corrosion.

- Minute-level installation: Grooved connection requires only 3 steps (align pipes → clamp → bolts), 90% faster than flange connections.

- Full size coverage: 1“-24” meets all needs from residential branch pipes to industrial main pipes, UL/FM certification ensures fire system safety.

packing

- Smart Graded Packaging:

- ≤4 inches: 12 pieces per box, PE bag + bubble wrap, paper box with compartments to prevent collision;

- >4 inches: Single suspended wooden box, three-way interface with EVA protective cap, hollow box design for easy forklift handling.

- Error-proofing Identification System:

- Product body laser-engraved type identification (Short/Standard/Long);

- Outer box labeled with three-color tags for type classification (Blue label = Short type/Green label = Standard/Red label = Long type).

- Revolutionary protection for large items:

- 10“-24” long three-way connectors use a removable steel frame structure, with magnetic dust covers embedded at the interface;

- Equipped with RFID electronic tags, scan to access installation videos and pressucapacity parameters.

- Transportation safety technology:

- Acceleration sensors built into wooden boxes automatically alarm during transportation in case of abnormal vibrations;

- Stack height limit labels (≤3 layers) printed on all six sides of the box.

Available size

Size | Center to end,L(mm) | |||

Inch | DN | mm | Short | Standard |

1″ | 25 | 33.7 | 57 | 57 |

1-1/4″ | 32 | 42.4 | 60 | 70 |

1-1/2″ | 40 | 48.3 | 60 | 70 |

2″ | 50 | 60.3 | 70 | 83 |

2-1/2″ | 65 | 73.0 | 76 | 95 |

2-1/2″ | 65 | 76.1 | 76 | 95 |

3″ | 80 | 88.9 | 86 | 108 |

4″ | 100 | 114.3 | 101 | 127 |

5″ | 125 | 139.7 | 124 | 140 |

5″ | 125 | 141.3 | 124 | 140 |

6″ | 150 | 165.1 | 140 | 165 |

6″ | 150 | 168.3 | 140 | 165 |

8″ | 200 | 219.1 | 175 | 197 |

10″ | 250 | 273.0 | 215 | 229 |

12″ | 300 | 323.9 | 245 | 254 |

14″ | 350 | 355.6 | / | 280 |

16″ | 400 | 406.4 | / | 305 |

18″ | 450 | 457.2 | / | 342 |

20″ | 500 | 508 | / | 381 |

24″ | 600 | 609.6 | / | 432 |

- Main pipeline diversion system: fire sprinkler piping network, HVAC main trunk pipes, achieving equal-diameter vertical branches to ensure balanced diversion flow.

- Equipment parallel connection: multiple devices in the pump room are connected in parallel for water supply/return, with three-way connectors reducing welding joints and lowering the risk of leakage.

- Space-optimized layout: building mechanical and electrical pipe shafts, ship pipe compartments, compact design (especially short types) saving 30% of installation space.

- Industrial Circulation System: Cooling tower circulation water and chemical medium transportation, with equal-diameter structures to prevent cavitation caused by sudden changes in local flow velocity.

- System Expansion and Renovation: Municipal water supply/industrial pipeline network upgrades, allowing new branches to be added without replacing the main pipeline (e.g., community water supply expansion).

- Dual types cover all scenarios:

- Short: Suitable for space-constrained areas (such as equipment compartments);

- Standard: Preferred for conventional branches, with less fluid disturbance;

- Long Type (Long) (14“-24”): Designed for extra-large pipe diameters, reducing high-pressure water hammer impact.

- Zero flow loss design: Equal-diameter three-way interface, branch pipe flow attenuation <5%, outperforming unequal-diameter tees.

- Triple sealing assurance:

- Ductile iron body (ASTM A536) resists deformation;

- Grooved ends with dual sealing rings for seismic resistance and anti-loosening;

- Hot-dip galvanized coating (≥80μm) resists chemical corrosion.

- Minute-level installation: Grooved connection requires only 3 steps (align pipes → clamp → bolts), 90% faster than flange connections.

- Full size coverage: 1“-24” meets all needs from residential branch pipes to industrial main pipes, UL/FM certification ensures fire system safety.

- Smart Graded Packaging:

- ≤4 inches: 12 pieces per box, PE bag + bubble wrap, paper box with compartments to prevent collision;

- >4 inches: Single suspended wooden box, three-way interface with EVA protective cap, hollow box design for easy forklift handling.

- Error-proofing Identification System:

- Product body laser-engraved type identification (Short/Standard/Long);

- Outer box labeled with three-color tags for type classification (Blue label = Short type/Green label = Standard/Red label = Long type).

- Revolutionary protection for large items:

- 10“-24” long three-way connectors use a removable steel frame structure, with magnetic dust covers embedded at the interface;

- Equipped with RFID electronic tags, scan to access installation videos and pressucapacity parameters.

- Transportation safety technology:

- Acceleration sensors built into wooden boxes automatically alarm during transportation in case of abnormal vibrations;

- Stack height limit labels (≤3 layers) printed on all six sides of the box.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.