HOT PRODUCTS TAGS

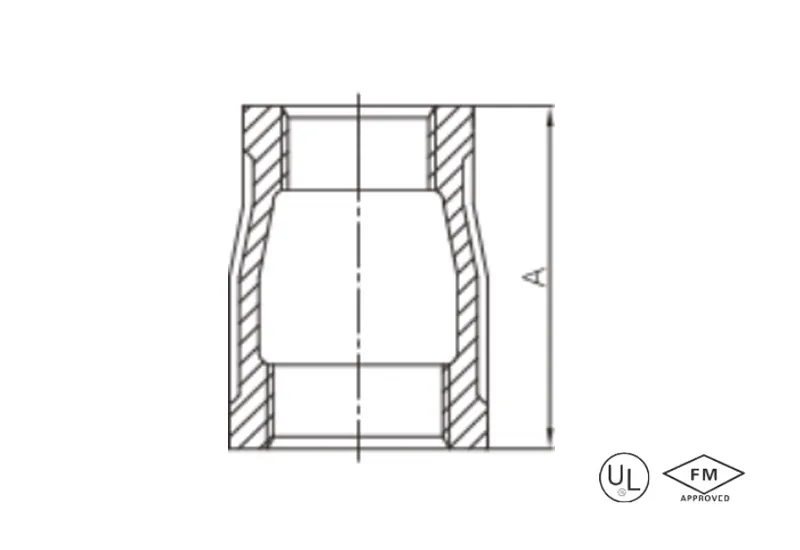

Malleable cast iron reducing socket (Reducing coupling / Reducer)

·Standard: ISO 49 / EN 10242

UL/FM

·Material: BS EN 1562, EN-GJMB-350-10

·Thread: BSPT

·W. pressure: 20 ~ 25 bar, ≤ PN25

·Surface: Black iron / hot dip galvanized

·Size Range: 3/8″ x 1/4″—4″ x 3″

description

Malleable cast iron reducing socket, seamless diameter-changing connection, fits multiple pipe diameters, pressure-resistant, leak-proof, easy to install.

Specification

Available size

SIZE | A | ||

INCH | DN | MM | MM |

3/8″ x 1/4″ | 10 x 8 | 17.2 x 13.5 | 30 |

1/2″ x 1/4″ | 15 x 8 | 21.3 x 13.5 | 36 |

1/2″ x 3/8″ | 15 x 10 | 21.3 x 17.2 | 36 |

3/4″ x 1/4″ | 20 x 8 | 26.9 x 13.5 | 39 |

3/4″ x 3/8″ | 20 x 10 | 26.9 x 17.2 | 39 |

3/4″ x 1/2″ | 20 x 15 | 26.9 x 21.3 | 39 |

1″ x 3/8″ | 25 x 10 | 33.7 x 17.2 | 45 |

1″ x 1/2″ | 25 x 15 | 33.7 x 21.3 | 45 |

1″ x 3/4″ | 25 x 20 | 33.7 x 26.9 | 45 |

1-1/4″ x 1/2″ | 32 x 15 | 42.4 x 21.3 | 50 |

1-1/4″ x 3/4″ | 32 x 20 | 42.4 x 26.9 | 50 |

1-1/4″ x 1″ | 32 x 25 | 42.4 x 33.7 | 50 |

1-1/2″ x 1/2″ | 40 x 15 | 48.3 x 21.3 | 55 |

1-1/2″ x 3/4″ | 40 x 20 | 48.3 x 26.9 | 55 |

1-1/2″ x 1″ | 40 x 25 | 48.3 x 33.7 | 55 |

1-1/2″ x 1-1/4″ | 40 x 32 | 48.3 x 42.4 | 55 |

2″ x 1/2″ | 50 x 15 | 60.3 x 21.3 | 65 |

2″ x 3/4″ | 50 x 20 | 60.3 x 26.9 | 65 |

2″ x 1″ | 50 x 25 | 60.3 x 33.7 | 65 |

2″ x 1-1/4″ | 50 x 32 | 60.3 x 42.4 | 65 |

2″ x 1-1/2″ | 50 x 40 | 60.3 x 48.3 | 65 |

2-1/2″ x 1/2″ | 65 x 15 | 76.1 x 21.3 | 74 |

2-1/2″ x 3/4″ | 65 x 20 | 76.1 x 26.9 | 74 |

2-1/2″ x 1″ | 65 x 25 | 76.1 x 33.7 | 74 |

2-1/2″ x 1-1/4″ | 65 x 32 | 76.1 x 42.4 | 74 |

2-1/2″ x 1-1/2″ | 65 x 40 | 76.1 x 48.3 | 74 |

2-1/2″ x 2″ | 65 x 50 | 76.1 x 60.3 | 74 |

3″ x 1/2″ | 80 x 15 | 76.1 x 21.3 | 80 |

3″ x 3/4″ | 80 x 20 | 88.9 x 26.9 | 80 |

3″ x 1″ | 80 x 25 | 88.9 x 33.7 | 80 |

3″ x 1-1/4″ | 80 x 32 | 88.9 x 42.4 | 80 |

3″ x 1-1/2″ | 80 x 40 | 88.9 x 48.3 | 80 |

3″ x 2″ | 80 x 50 | 88.9 x 60.3 | 80 |

3″ x 2-1/2″ | 80 x 65 | 88.9 x 76.1 | 80 |

4″ x 1″ | 100 x 25 | 114.3 x 33.7 | 94 |

4″ x 1-1/4″ | 100 x 32 | 114.3 x 42.4 | 94 |

4″ x 1-1/2″ | 100 x 40 | 114.3 x 48.3 | 94 |

4″ x 2″ | 100 x 50 | 114.3 x 60.3 | 94 |

4″ x 2-1/2″ | 100 x 65 | 114.3 x 76.1 | 94 |

4″ x 3″ | 100 x 80 | 114.3 x 88.9 | 94 |

Note: NSF 61 certificate is available for M2406 ~ M2453, except M2403, M2405, M2412.

application

- Chemical system renovation: Different diameter pipe clamps seamlessly connect the pressure gradients at the inlet and outlet of the reaction device.

- Fire protection network upgrade: UL-certified variable diameter connections ensure high-pressure integration of multiple pipe specifications in sprinkler systems.

- Ship power maintenance: Zero leakage connections for fuel/cooling water pipes of different diameters in the engine room under vibration conditions.

- Municipal water supply optimization: Leak-free connections between large-diameter main pipes and old branch pipes in water-saving renovations.

- Industrial Equipment Integration: Eliminate turbulent energy loss in compressor inlet/outlet pipes with different diameters.

- Mining Conveyance Network: High-wear-resistant pipe clamps for different diameters resist impact wear in slurry pipeline sections with different diameters.

- Agricultural Irrigation Hub: Rapid maintenance connections between main pipelines and branch pipelines with stepped different diameters at pump stations.

- Energy Pipeline System Retrofit: 4-inch large-diameter pipeline extensions with different diameters without welding.

advantages

- Dual-diameter high-pressure sealing: 25 bar operating conditions with different diameter BSPT tapered threads ensure zero leakage in both directions.

- NSF safety certification: Specific models feature a zinc-plated layer for drinking water applications, eliminating the risk of heavy metal leaching.

- Full range of diameter coverage: From 1/4“ to 4” diameter, suitable for applications ranging from miniature instruments to main pipeline renovations.

- Fluid Optimization Design: Conical flow channels ensure smooth medium transition in variable diameter sections with pressure loss ≤5%.

- Armor-Grade Corrosion Resistance: Hot-dip galvanized coating passes 3,000-hour industrial acid/alkali and salt spray tests.

- Vibration-resistant structure reinforcement: Thickened variable diameter wall design enhances impact resistance by 50% compared to standard components.

- Installation efficiency revolution: Single-piece replacement of flange assemblies + variable diameter pipes saves 85% installation time.

- Heavy-duty diameter assurance: 4-inch variable diameter pipe clamps maintain a 25 bar pressure-bearing structure with zero deformation.

packing

- Stepped port protection: dual-specification injection-molded caps nested with different diameter threads + silicone sealing rings.

- Conical cushioning system: EPE pearl cotton molded variable-diameter curved surface adaptive wrapping.

- Anti-corrosion armor layer: vapor-phase anti-corrosion film + honeycomb aluminum plate composite vacuum sealing.

- Precision anti-error structure: laser-cut pine wood irregular slots fitted and locked according to dimensions.

- Heavy-duty load-bearing solution: I-beam steel frame fumigated wooden box (compatible with DN100 load-bearing capacity).

- Anti-rolling design: inner box V-shaped steel rails locking tube clamps for zero displacement during transportation.

Available size

SIZE | A | ||

INCH | DN | MM | MM |

3/8″ x 1/4″ | 10 x 8 | 17.2 x 13.5 | 30 |

1/2″ x 1/4″ | 15 x 8 | 21.3 x 13.5 | 36 |

1/2″ x 3/8″ | 15 x 10 | 21.3 x 17.2 | 36 |

3/4″ x 1/4″ | 20 x 8 | 26.9 x 13.5 | 39 |

3/4″ x 3/8″ | 20 x 10 | 26.9 x 17.2 | 39 |

3/4″ x 1/2″ | 20 x 15 | 26.9 x 21.3 | 39 |

1″ x 3/8″ | 25 x 10 | 33.7 x 17.2 | 45 |

1″ x 1/2″ | 25 x 15 | 33.7 x 21.3 | 45 |

1″ x 3/4″ | 25 x 20 | 33.7 x 26.9 | 45 |

1-1/4″ x 1/2″ | 32 x 15 | 42.4 x 21.3 | 50 |

1-1/4″ x 3/4″ | 32 x 20 | 42.4 x 26.9 | 50 |

1-1/4″ x 1″ | 32 x 25 | 42.4 x 33.7 | 50 |

1-1/2″ x 1/2″ | 40 x 15 | 48.3 x 21.3 | 55 |

1-1/2″ x 3/4″ | 40 x 20 | 48.3 x 26.9 | 55 |

1-1/2″ x 1″ | 40 x 25 | 48.3 x 33.7 | 55 |

1-1/2″ x 1-1/4″ | 40 x 32 | 48.3 x 42.4 | 55 |

2″ x 1/2″ | 50 x 15 | 60.3 x 21.3 | 65 |

2″ x 3/4″ | 50 x 20 | 60.3 x 26.9 | 65 |

2″ x 1″ | 50 x 25 | 60.3 x 33.7 | 65 |

2″ x 1-1/4″ | 50 x 32 | 60.3 x 42.4 | 65 |

2″ x 1-1/2″ | 50 x 40 | 60.3 x 48.3 | 65 |

2-1/2″ x 1/2″ | 65 x 15 | 76.1 x 21.3 | 74 |

2-1/2″ x 3/4″ | 65 x 20 | 76.1 x 26.9 | 74 |

2-1/2″ x 1″ | 65 x 25 | 76.1 x 33.7 | 74 |

2-1/2″ x 1-1/4″ | 65 x 32 | 76.1 x 42.4 | 74 |

2-1/2″ x 1-1/2″ | 65 x 40 | 76.1 x 48.3 | 74 |

2-1/2″ x 2″ | 65 x 50 | 76.1 x 60.3 | 74 |

3″ x 1/2″ | 80 x 15 | 76.1 x 21.3 | 80 |

3″ x 3/4″ | 80 x 20 | 88.9 x 26.9 | 80 |

3″ x 1″ | 80 x 25 | 88.9 x 33.7 | 80 |

3″ x 1-1/4″ | 80 x 32 | 88.9 x 42.4 | 80 |

3″ x 1-1/2″ | 80 x 40 | 88.9 x 48.3 | 80 |

3″ x 2″ | 80 x 50 | 88.9 x 60.3 | 80 |

3″ x 2-1/2″ | 80 x 65 | 88.9 x 76.1 | 80 |

4″ x 1″ | 100 x 25 | 114.3 x 33.7 | 94 |

4″ x 1-1/4″ | 100 x 32 | 114.3 x 42.4 | 94 |

4″ x 1-1/2″ | 100 x 40 | 114.3 x 48.3 | 94 |

4″ x 2″ | 100 x 50 | 114.3 x 60.3 | 94 |

4″ x 2-1/2″ | 100 x 65 | 114.3 x 76.1 | 94 |

4″ x 3″ | 100 x 80 | 114.3 x 88.9 | 94 |

Note: NSF 61 certificate is available for M2406 ~ M2453, except M2403, M2405, M2412.

- Chemical system renovation: Different diameter pipe clamps seamlessly connect the pressure gradients at the inlet and outlet of the reaction device.

- Fire protection network upgrade: UL-certified variable diameter connections ensure high-pressure integration of multiple pipe specifications in sprinkler systems.

- Ship power maintenance: Zero leakage connections for fuel/cooling water pipes of different diameters in the engine room under vibration conditions.

- Municipal water supply optimization: Leak-free connections between large-diameter main pipes and old branch pipes in water-saving renovations.

- Industrial Equipment Integration: Eliminate turbulent energy loss in compressor inlet/outlet pipes with different diameters.

- Mining Conveyance Network: High-wear-resistant pipe clamps for different diameters resist impact wear in slurry pipeline sections with different diameters.

- Agricultural Irrigation Hub: Rapid maintenance connections between main pipelines and branch pipelines with stepped different diameters at pump stations.

- Energy Pipeline System Retrofit: 4-inch large-diameter pipeline extensions with different diameters without welding.

- Dual-diameter high-pressure sealing: 25 bar operating conditions with different diameter BSPT tapered threads ensure zero leakage in both directions.

- NSF safety certification: Specific models feature a zinc-plated layer for drinking water applications, eliminating the risk of heavy metal leaching.

- Full range of diameter coverage: From 1/4“ to 4” diameter, suitable for applications ranging from miniature instruments to main pipeline renovations.

- Fluid Optimization Design: Conical flow channels ensure smooth medium transition in variable diameter sections with pressure loss ≤5%.

- Armor-Grade Corrosion Resistance: Hot-dip galvanized coating passes 3,000-hour industrial acid/alkali and salt spray tests.

- Vibration-resistant structure reinforcement: Thickened variable diameter wall design enhances impact resistance by 50% compared to standard components.

- Installation efficiency revolution: Single-piece replacement of flange assemblies + variable diameter pipes saves 85% installation time.

- Heavy-duty diameter assurance: 4-inch variable diameter pipe clamps maintain a 25 bar pressure-bearing structure with zero deformation.

- Stepped port protection: dual-specification injection-molded caps nested with different diameter threads + silicone sealing rings.

- Conical cushioning system: EPE pearl cotton molded variable-diameter curved surface adaptive wrapping.

- Anti-corrosion armor layer: vapor-phase anti-corrosion film + honeycomb aluminum plate composite vacuum sealing.

- Precision anti-error structure: laser-cut pine wood irregular slots fitted and locked according to dimensions.

- Heavy-duty load-bearing solution: I-beam steel frame fumigated wooden box (compatible with DN100 load-bearing capacity).

- Anti-rolling design: inner box V-shaped steel rails locking tube clamps for zero displacement during transportation.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.