ГОРЯЧИЕ ТЕГИ ПРОДУКТОВ

Редукционный фланцевый тройник с желобком

-Стандарт: ANSI / UL 213C FM

-Материал: Ковкий чугун ASTM A536, 65-45-12

-Номинальное давление: 300 - 500 фунтов на кв. дюйм

-Поверхность: Черная / красная окраска / горячая гальванизация

-Размерный ряд: 4”×4”×2-1/2”

описание

Редукционный фланцевый тройник с желобком - это трубопроводная арматура с желобчатой структурой соединения и фланцевым интерфейсом на одном конце. Используется для диагонального ответвления редукционных трубопроводов и в случаях, когда требуется фланцевое соединение

Технические характеристики

Доступный размер

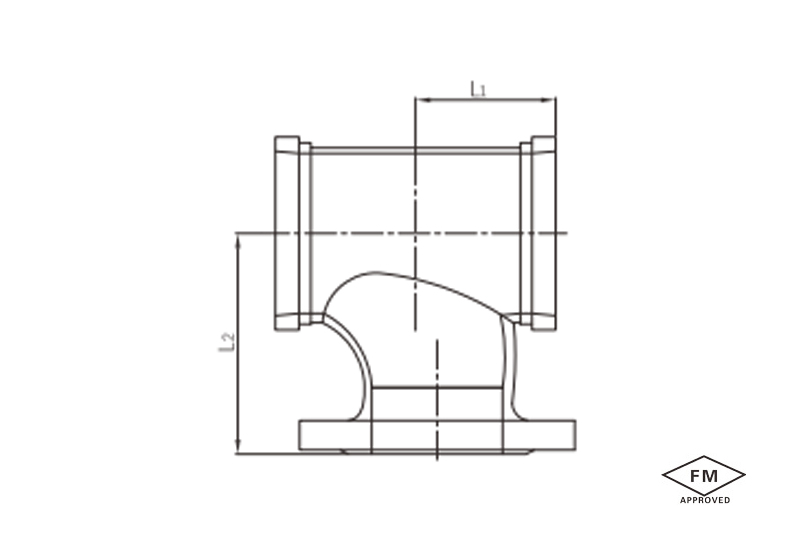

| Размер | Центр на конец (мм) | |||

| Дюйм | DN | мм | L1 | L2 |

| 4” × 4” × 2-1/2” | 100 × 100 × 65 | 114.3 × 114.3 × 76.1 | 96 | 134.5 |

приложение

- Полусварное соединение: Полусварное соединение используется для систем наклонных ответвлений, которые необходимо соединить между желобчатыми трубами и фланцевым оборудованием, например, адаптацией выхода насоса или клапана.

- Проект с ограниченным пространством: Этот вид конструкции может адаптироваться к требованиям проекта обхода трубопровода, и широко используется в плотном оборудовании, например, на химических заводах и в помещении трубопровода энергетической станции.

- Модернизация и расширение системы: упрощает подключение труб различного диаметра и фланцевого интерфейса оборудования (например, фильтров, расходомеров), уменьшает использование переходников.

преимущества

1. Интегрированные многофункциональные функции: цельный патрубок и патрубок с горизонтальными и вертикальными отверстиями под болты для подключения к водопроводу, обычные фланцевые соединения ответвлений; уменьшение угла наклона на 45 градусов снижает сложность монтажа

2. Безопасность уплотнения: Предварительно установленный уплотнительный паз на концах фланца соответствует стандартным прокладкам; конец повторно затягивается против разъединения, обеспечивая двустороннюю защиту герметичности при высоком давлении.

3. Использование материала из ковкого чугуна (ASTM A536) обеспечивает эффективную коррозионную стойкость, а обработка поверхности черной краской / красной краской / горячим цинкованием позволяет использовать их на открытом воздухе в течение длительного времени.

4. Преимущества установки: Отсутствие сварки благодаря конструкции канавок и предварительно выровненным отверстиям под фланцевые болты, что увеличивает скорость работы на месте установки более чем на 50%.

5. Сертификация надлежащая международная: ANSI/UL/FM сертификация, до 300-500 psi давление поддерживается противопожарные и промышленные системы безопасны для использования

упаковка

- Защита поверхности фланцевого соединения: Пластиковый колпачок и антикоррозийная пленка добавляются к фланцевым соединениям, силиконовая пробка используется для блокировки болтового отверстия, чтобы предотвратить деформацию

- Многослойная усиленная упаковка: модуль из пенополистирола EPS вложен в основной корпус, опорная рама из гофрированного картона добавлена к наклонной секции патрубка, и весь упаковочный слой со сталью внутри деревянного ящика.

- Интеллектуальная система идентификации: Коробка со стрелкой, обозначающей фланец со знаком ↑, рейтингом и QR-кодом.

Доступный размер

| Размер | Центр на конец (мм) | |||

| Дюйм | DN | мм | L1 | L2 |

| 4” × 4” × 2-1/2” | 100 × 100 × 65 | 114.3 × 114.3 × 76.1 | 96 | 134.5 |

- Полусварное соединение: Полусварное соединение используется для систем наклонных ответвлений, которые необходимо соединить между желобчатыми трубами и фланцевым оборудованием, например, адаптацией выхода насоса или клапана.

- Проект с ограниченным пространством: Этот вид конструкции может адаптироваться к требованиям проекта обхода трубопровода, и широко используется в плотном оборудовании, например, на химических заводах и в помещении трубопровода энергетической станции.

- Модернизация и расширение системы: упрощает подключение труб различного диаметра и фланцевого интерфейса оборудования (например, фильтров, расходомеров), уменьшает использование переходников.

1. Интегрированные многофункциональные функции: цельный патрубок и патрубок с горизонтальными и вертикальными отверстиями под болты для подключения к водопроводу, обычные фланцевые соединения ответвлений; уменьшение угла наклона на 45 градусов снижает сложность монтажа

2. Безопасность уплотнения: Предварительно установленный уплотнительный паз на концах фланца соответствует стандартным прокладкам; конец повторно затягивается против разъединения, обеспечивая двустороннюю защиту герметичности при высоком давлении.

3. Использование материала из ковкого чугуна (ASTM A536) обеспечивает эффективную коррозионную стойкость, а обработка поверхности черной краской / красной краской / горячим цинкованием позволяет использовать их на открытом воздухе в течение длительного времени.

4. Преимущества установки: Отсутствие сварки благодаря конструкции канавок и предварительно выровненным отверстиям под фланцевые болты, что увеличивает скорость работы на месте установки более чем на 50%.

5. Сертификация надлежащая международная: ANSI/UL/FM сертификация, до 300-500 psi давление поддерживается противопожарные и промышленные системы безопасны для использования

- Защита поверхности фланцевого соединения: Пластиковый колпачок и антикоррозийная пленка добавляются к фланцевым соединениям, силиконовая пробка используется для блокировки болтового отверстия, чтобы предотвратить деформацию

- Многослойная усиленная упаковка: модуль из пенополистирола EPS вложен в основной корпус, опорная рама из гофрированного картона добавлена к наклонной секции патрубка, и весь упаковочный слой со сталью внутри деревянного ящика.

- Интеллектуальная система идентификации: Коробка со стрелкой, обозначающей фланец со знаком ↑, рейтингом и QR-кодом.

Получите коммерческое предложение на заказ стальных труб сегодня!

Предоставьте нам детали вашего проекта (например, применение, спецификации, количество). Наша опытная команда предложит индивидуальное решение и конкурентоспособное предложение в течение 24 рабочих часов.